Company Brief Introduction

Jiangsu Xinrongplas Machinery Co., Ltd.

Jiangsu Xinrongplas Machinery Co., Ltd.

Jiangsu Xinrongplas Machinery Co., Ltd was founded in year 1996. With continuous focusing on plastic extrusion machinery, we have gained a certain awareness as one of professional manufacturer.

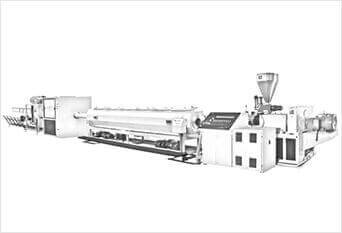

Our main products are: plastic pipe extrusion line, plastic profile extrusion line, plastic sheet extrusion line and plastic recycling machine.

We have provided turnkey project for more than 80 countries all over the world.

After many years’ development, now our company has modern workshop more than 50,000m².

Our team has grown up to 200 experienced staff.

Among them, 6 mechanical engineers to ensure innovation and development, they are also supported by 4 electrical and program engineers which to make whole system working stable and efficiently.

With more than 12 after sale engineers, everyone is after systematic learning and training. As we know the after sale service is the most important part of the turnkey project, our engineer can reach to your workshop within 72 hours all over the world.

We know the quality is the life of our company. Our company insists to manufacture all machine units by ourselves in order to control quality strictly by our quality inspectors. To implement this concept, we have built our own tooling and CNC workshop.

Even if some parts from our certified supplier, our quality inspector will check these parts before entering into our warehouse.

Warmly welcome to visit our workshop, and sincerely hope we can have long term cooperation in near future!

60000㎡

Factory Area

40000㎡

Workshop Area

200

Experienced Staff

20million

Annual Output Value

Jinagsu Xinrongplas Machinery Co., Ltd was founded by renting one workshop. And the company started to manufacture PEX-Al-PEX composite pipe extrusion line and small PE, PPR pipe extrusion line. From 1996 to 1998, the average annual sale is more than $10,000,000.

We moved to our own workshop and has successfully get certificate of ISO9001. We have developed larger diameter PE pipe extrusion line, size up to 450mm.

We have enriched the types of plastic extrusion machinery by adding PVC pipe extrusion line. And also developed our own belling machine for PVC pipe.

Company has expanded its sales network by establishing foreign sales department. In the same year, company has developed the first hollow wall winding pipe extrusion line in China, and act as one of the drafters for hollow wall winding pipe standard (GB/T 19472.2-2004).

Company successfully released PE double wall corrugated pipe extrusion line to add new types of drainage pipe into the market. And after extensive testing, we have designed the wave shape for corrugated mould for SN4 and SN8 pipe separately, in order to reach standard ring stiffness with lowest meter weight.

Company developed PE steel belt reinforced corrugated pipe extrusion line. This provided new idea about pipe type which is plastic and steel composite.

PE steel wire reinforced pipe extrusion line has been produced by our company. This pipe can replace pure PE pipe, and extend application of plastic and steel composite pipe to water and gas supply.

company has moved to new built workshop with area of 50,000m². Also, our machine size range, quality has improved continuously.

New designed single screw and barrel has been released by our company. The L/D ratio has increase from 33:1 to 38:1, realizing 30% increase in output capacity and 20% decrease in power consumption.

company announced socket injection machine which can inject socket/spigot on pipe directly. This provides a better way for pipe connection and reduce the manpower. ERA group high appreciated this machine and order more than 12 machines in this year.

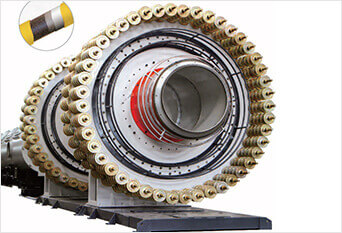

RTP pipe extrusion line is developed specially for high pressure fluid delivery, like oil, gas, etc. The maximum pressure can reach 200bar.

Company introduced new generation CNC machines to replace old ones to increase processing precision and capacity and reduce manpower further. In this case, quality of our machines have been a big step forward.

We upgraded the RTP winding machine, to make it working faster and more stable. And it can wind different types of UD tape such as steel wire tape, fiberglass tape, aramid tape, carbon fiber tape, basalt tape.

After 8 years of continuous research and development, testing and hard work, we successfully launched mature PVC-O pipe extrusion line, for pipe range 90 to 630mm, MRS class 500.

Our company keeping innovation and development, the story continues...