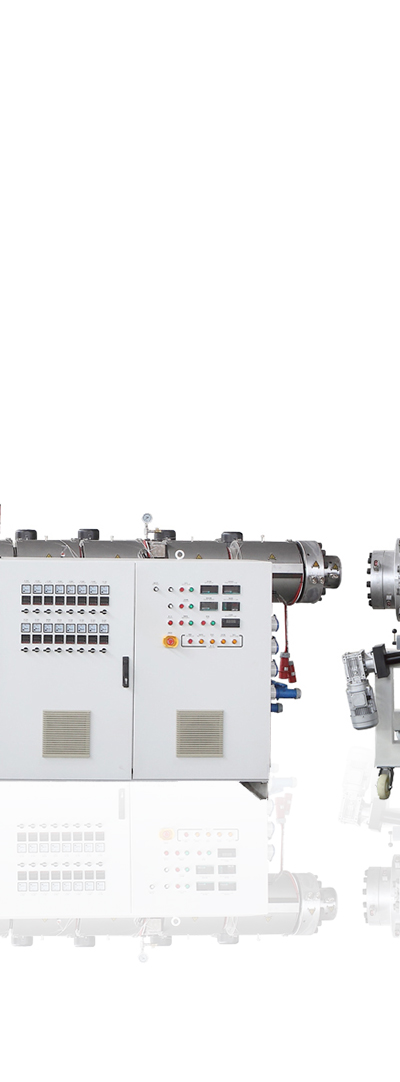

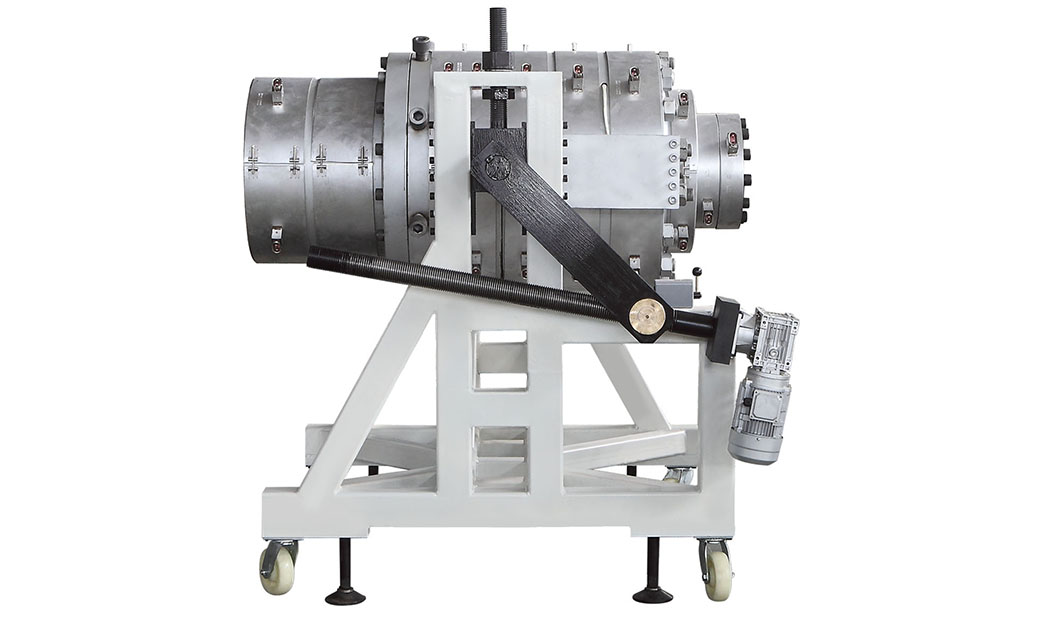

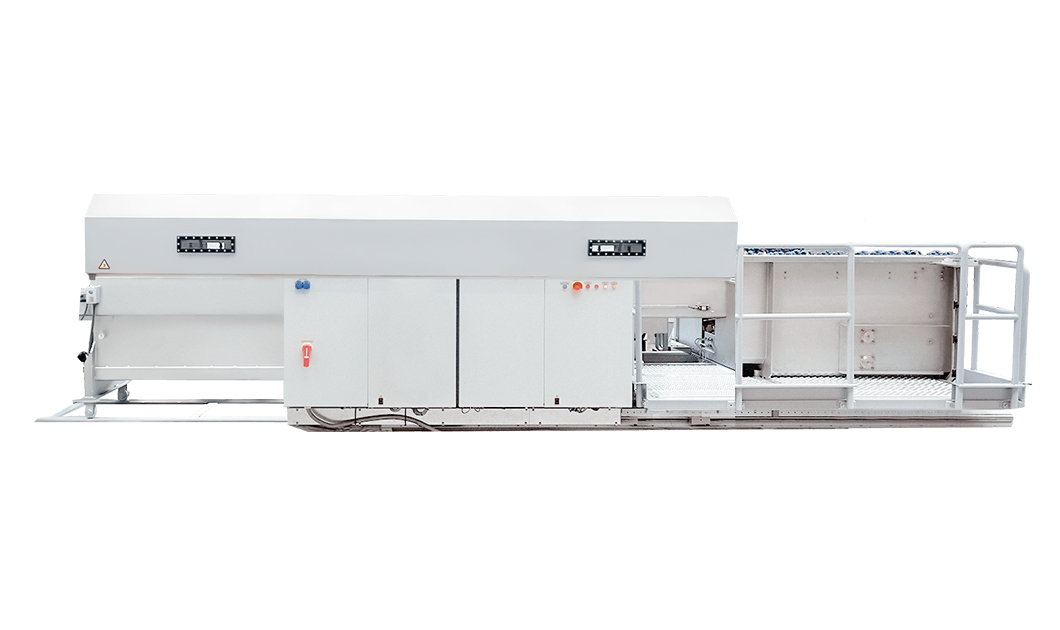

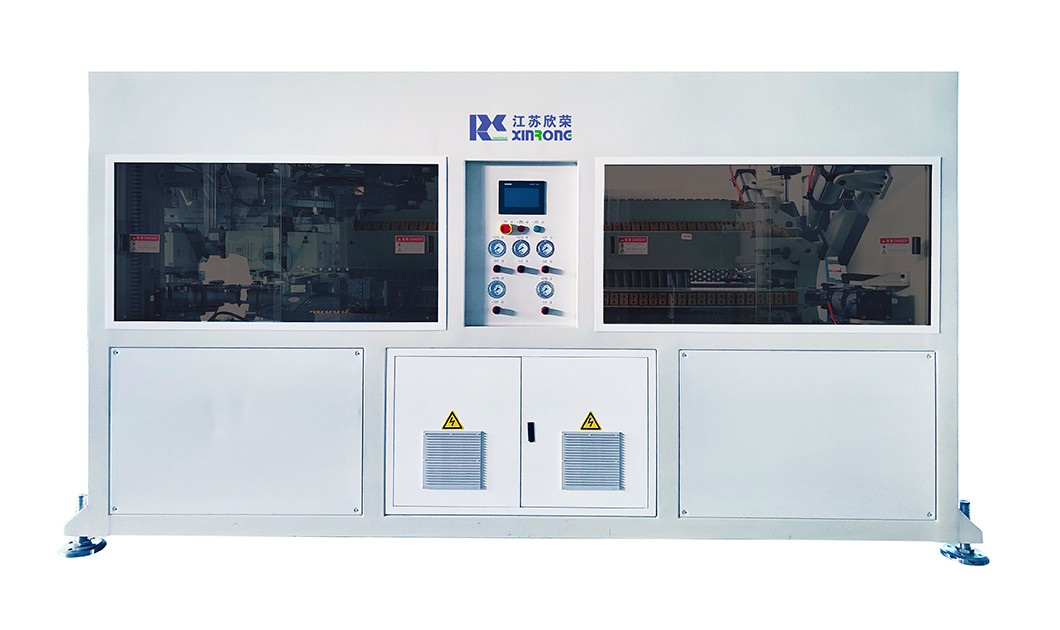

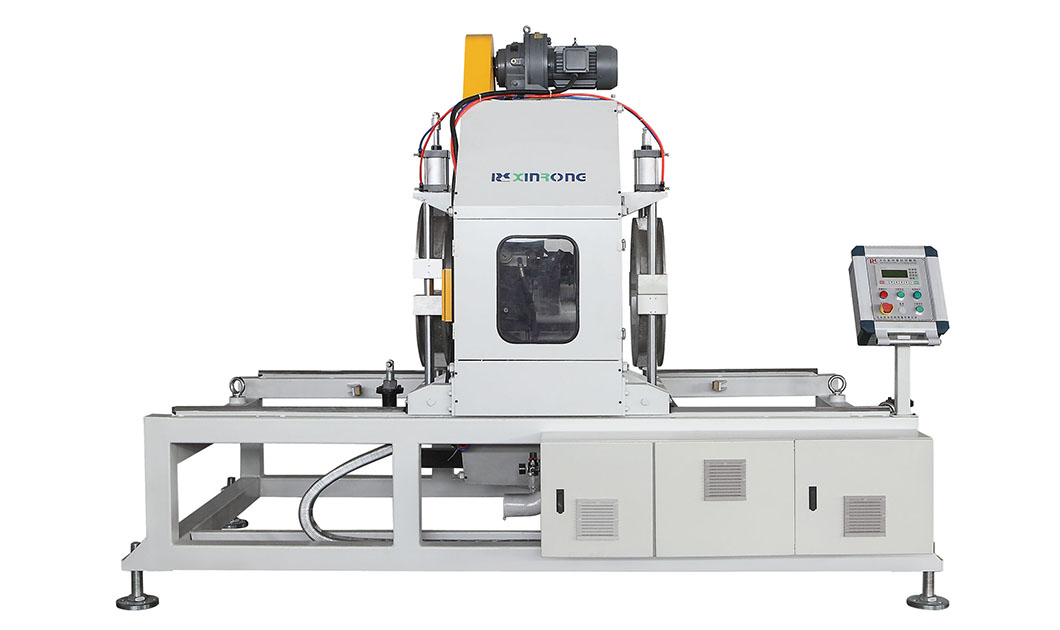

Machine Main Features

1. This is another equipment independently developed by our company for 8 years.

2. Real-time feedback of important data on pipe production which makes it easy to adjust the pipe production process.

3. With complete process storage function to facilitate future pipe production.

4. The entire line is highly automated, and the wall thickness is automatically adjusted through the gravimetric dosing system and the production line PLC to reduce material waste.

5. Equipped with a remote diagnosis system, when problems occur, we will provide customers with quick guidance and troubleshooting services based on the equipment operating parameters.