Adopt L/D ratio 38:1 screw for virgin material. Adopt L/D 33:1 screw for recycled material. We also have choice of twin screw and barrel for other material such PVC powder, PP powder, etc. Provide suitable extruder for different customer requirements.

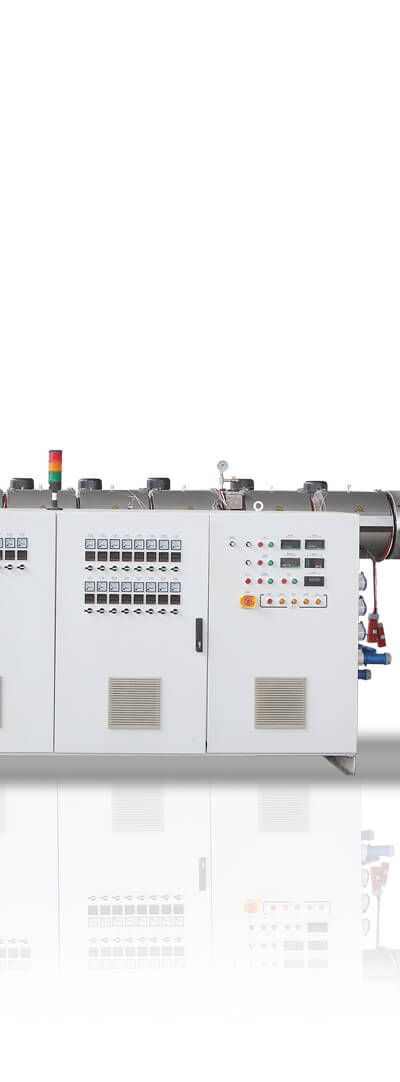

Read MoreTwin Screw Extruder

Twin Screw Extruder

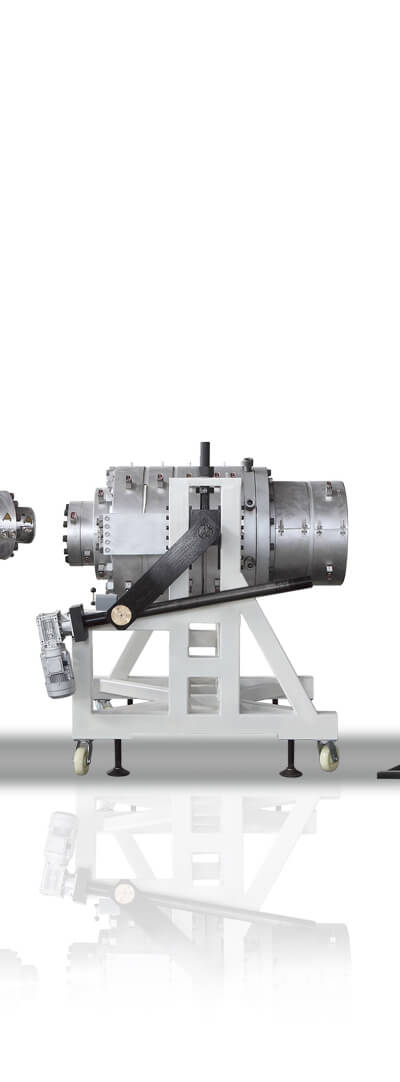

Extrusion Die Head

Vacuum Tank

Vacuum Tank

Vacuum Tank

Cooling Tank

Cooling Tank

Cooling Tank

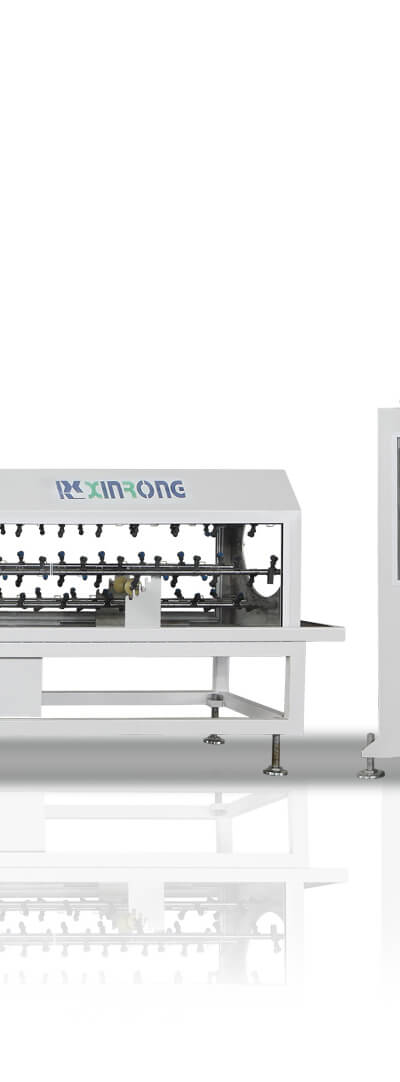

Haul off Unit

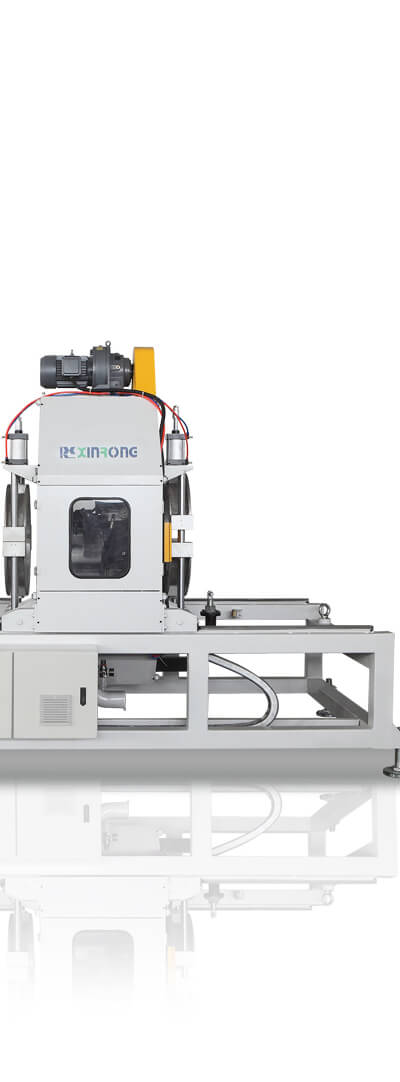

Cutter

Cutter

Full Automatic Belling Machine

Full Automatic Belling Machine

Full Automatic Belling Machine

Full Automatic Belling Machine

Full Automatic Belling Machine