Based on 33:1 L/D ratio for screw design, we have developed 38:1 L/D ratio. Compared with 33:1 ratio, 38:1 ratio has advantage of 100% plasticization, increase output capacity by 30%, reduce power consumption up to 30% and reach almost linear extrusion performance.

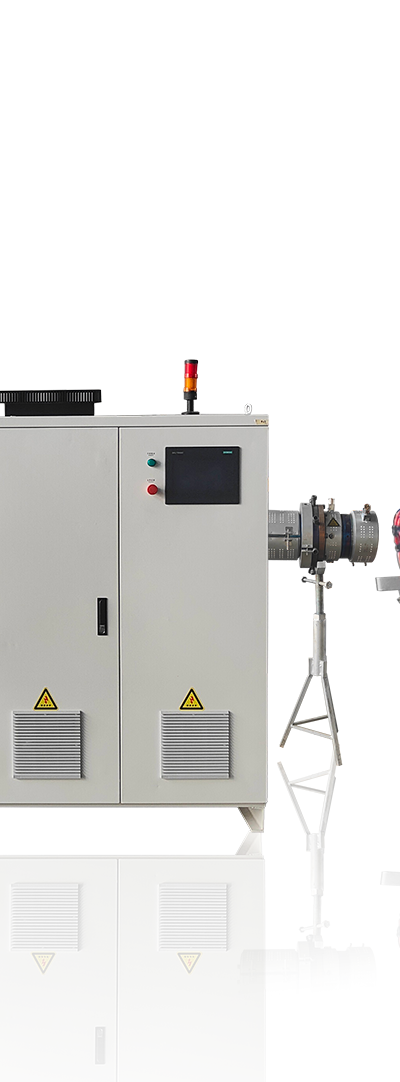

Read MoreSingle Screw Extruder and Die Head

Single Screw Extruder and Die Head

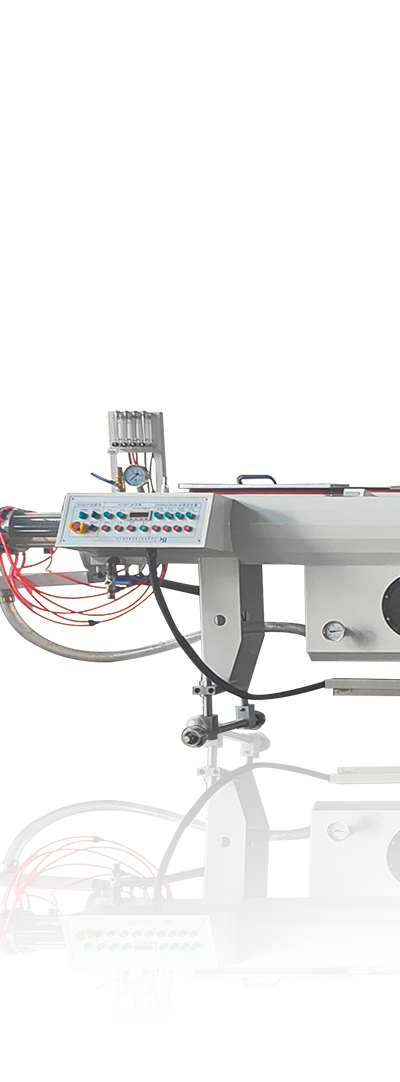

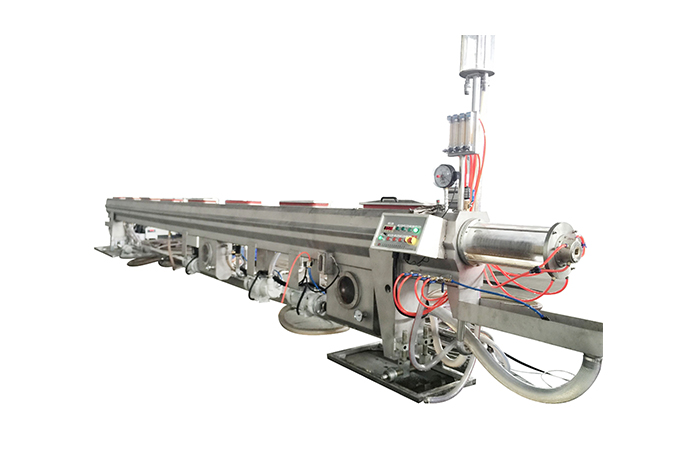

Vacuum Tank

Vacuum Tank

Vacuum Tank

Vacuum Tank

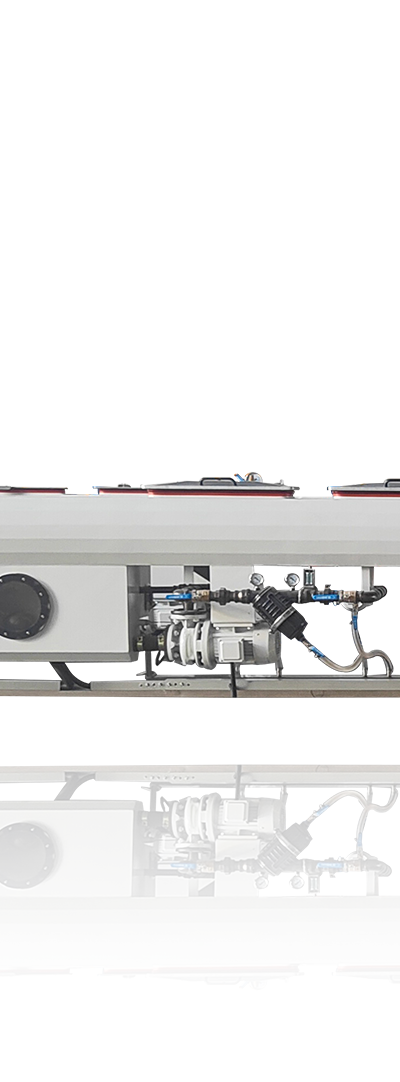

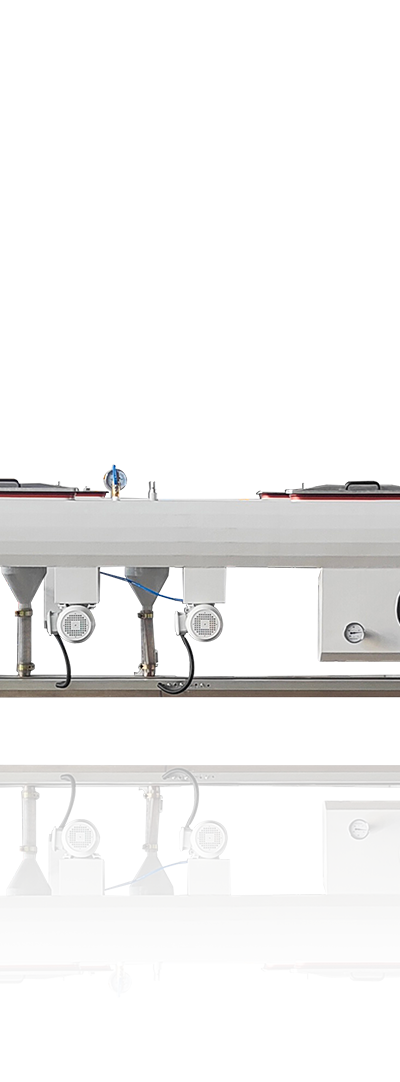

Cooling Tank

Cooling Tank

Cooling Tank

Haul-off Unit

Haul-off Unit

Cutter