Both conical twin screw extruder and parallel twin screw extruder can be applied to produce PVC pipe. With latest technology, to lower power and ensure capacity. According to different formula, we provide different screw design to ensure good plasticizing effect and high capacity...

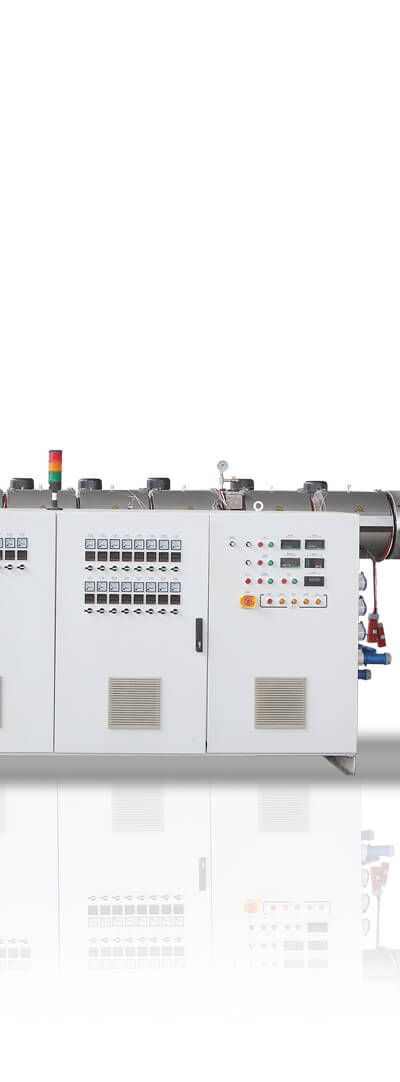

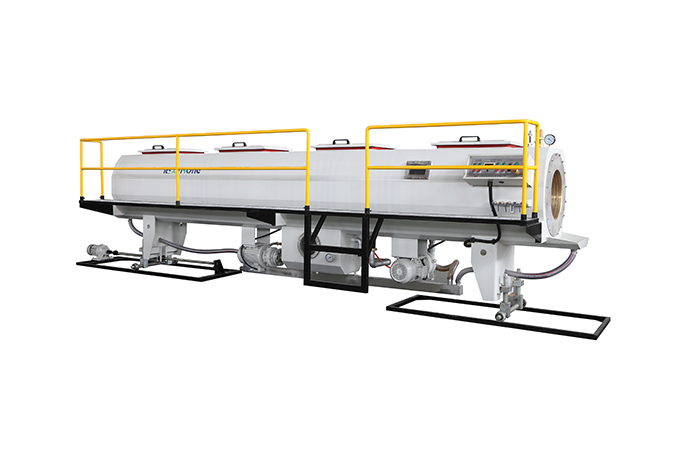

Read MoreTwin Screw Extruder

Twin Screw Extruder

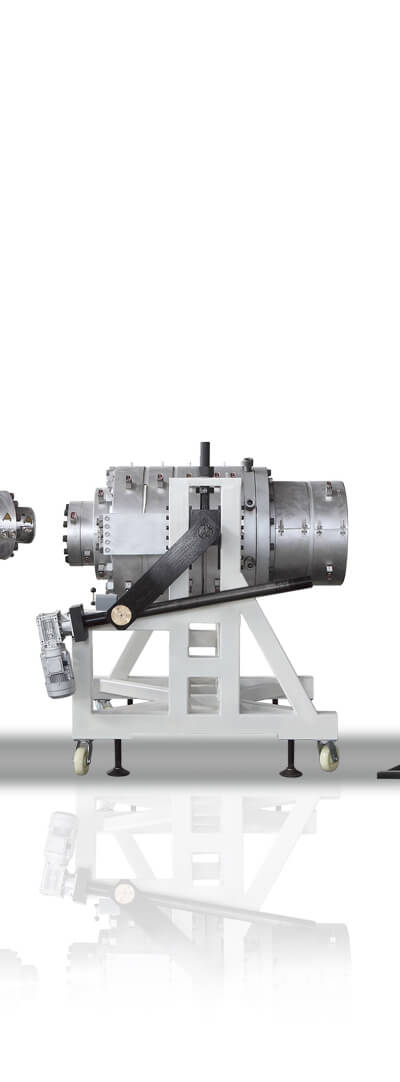

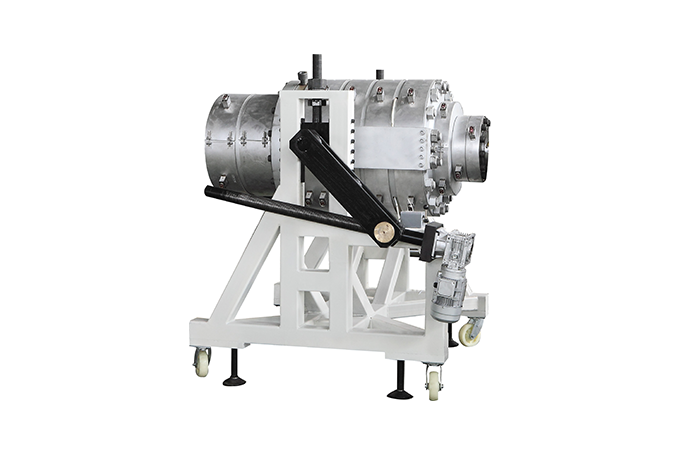

Extrusion Die Head

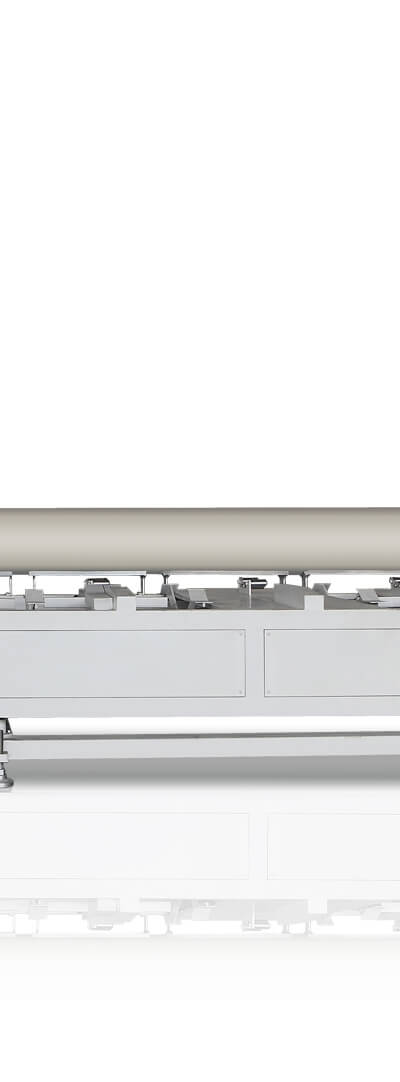

Vacuum Tank

Vacuum Tank

Vacuum Tank

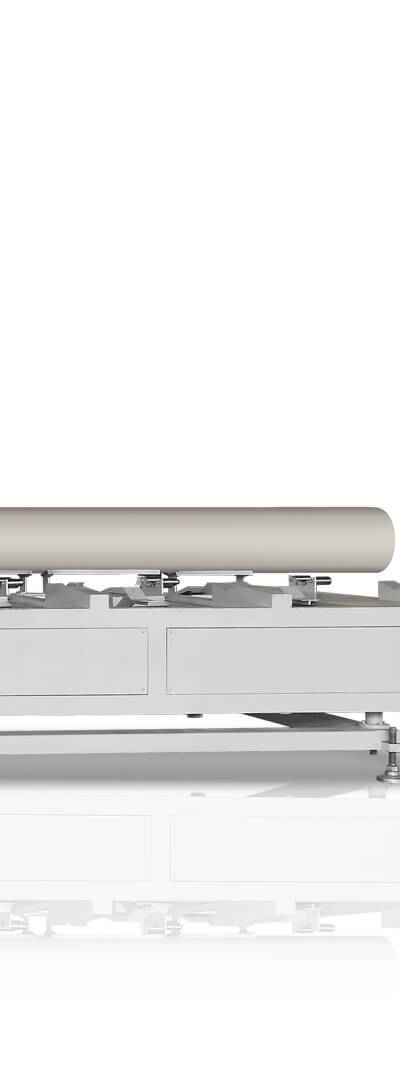

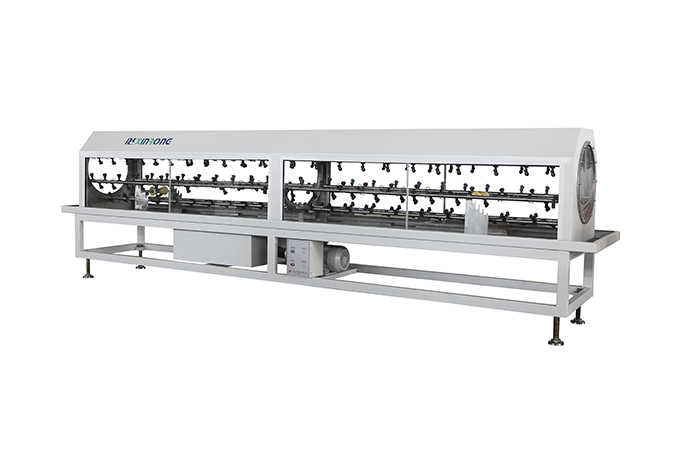

Cooling Tank

Cooling Tank

Cooling Tank

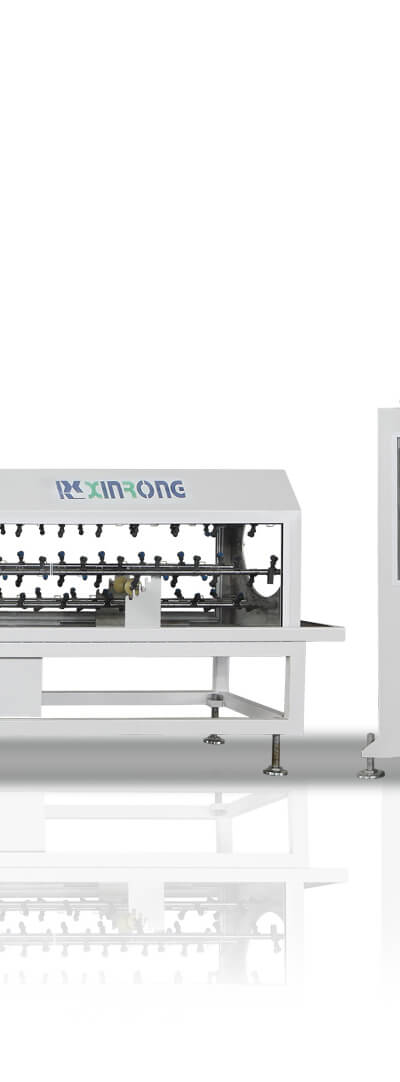

Haul off Unit

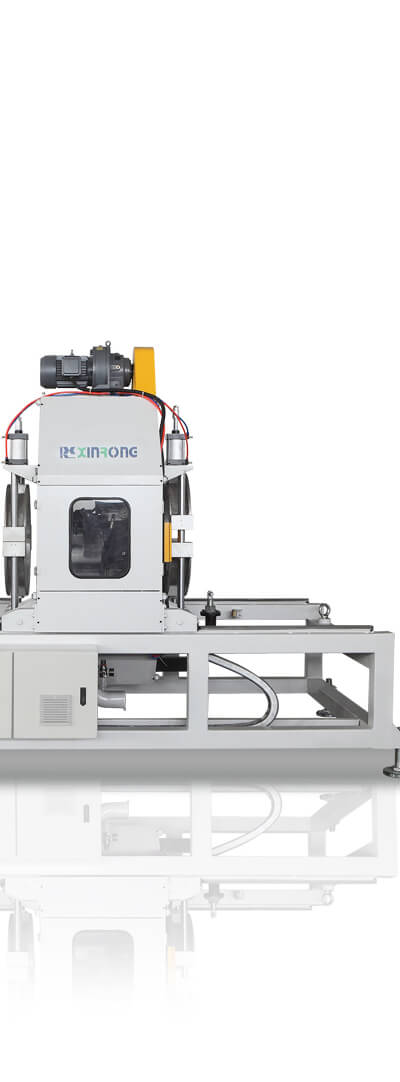

Cutter

Cutter

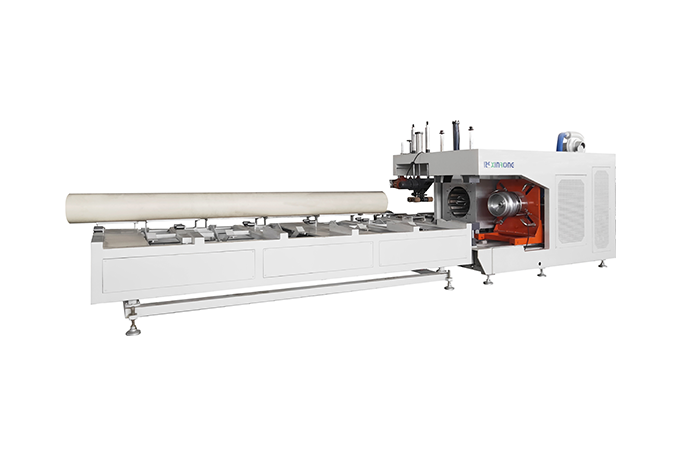

Full Automatic Belling Machine

Full Automatic Belling Machine

Full Automatic Belling Machine

Full Automatic Belling Machine

Full Automatic Belling Machine