Siemens Touch Screen and PLC

Operation can be done through touch screen and languages are interchangeable. All important parameters are shown in the screen.

Corrugator is used to place and move corrugated mould. Vacuum is created to absorb outer layer into corrugated mould to form corrugate shape. By moving corrugated mould, pipe is also pulled out from corrugator.

Get a Quote

Operation can be done through touch screen and languages are interchangeable. All important parameters are shown in the screen.

Electronically adjust upper frame for different size of corrugated mould. With four pillars, ensure stable and accurate adjustment.

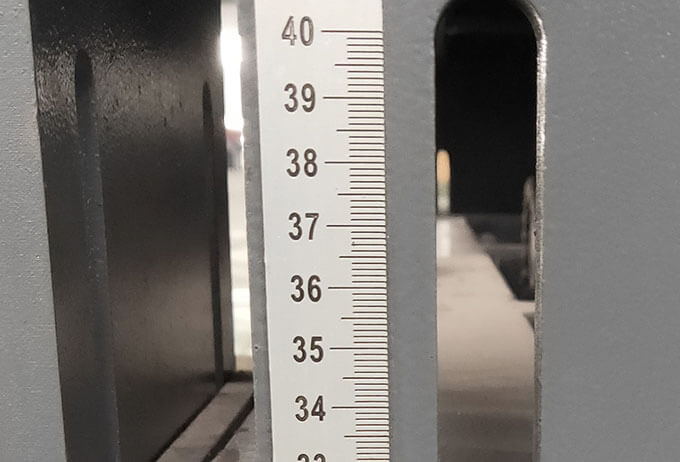

Electronically adjustment for whole frame. With ruler to show different position for different mould sizes.

To adjust tensity of mould moving, make mould moving smoothly.

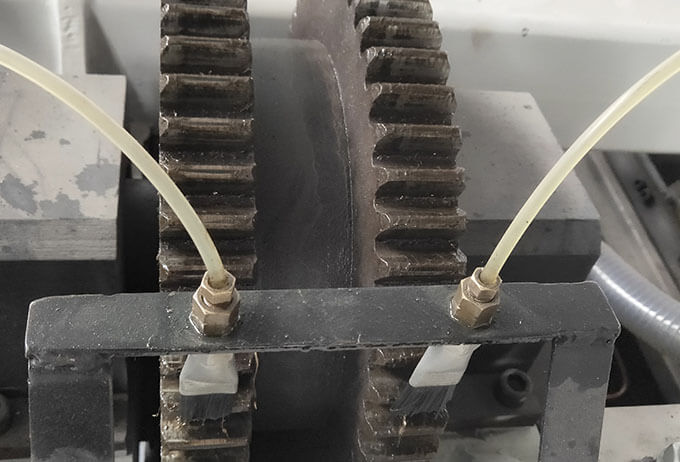

Automatic lubricate the gears to make corrugated mould moving smoothly.

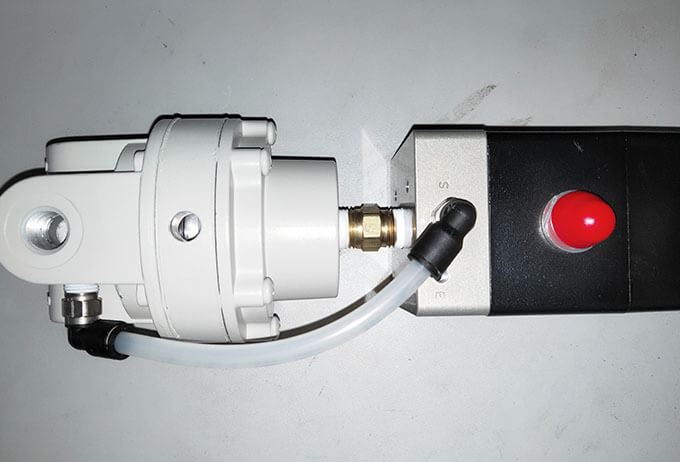

To control air more stable and accurate, to form good pipe and socket shape.

When power failure, UPS backup power power will supply power to corrugator to move pipe out from calibration sleeve. To avoid pipe stuck on the calibration sleeve after pipe cooling and shrinkage.

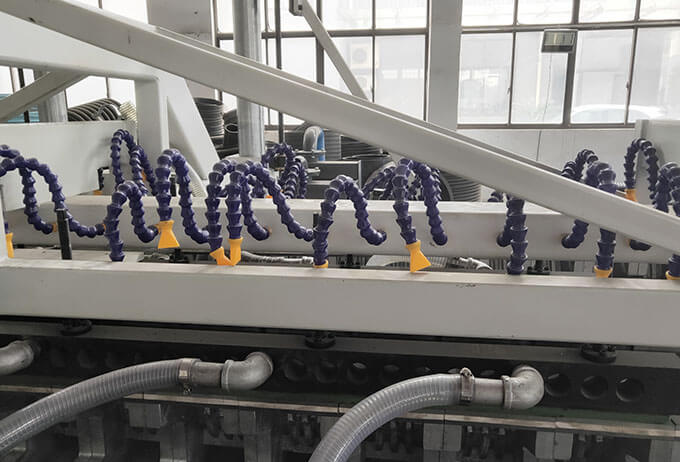

With both water cooling and air cooling system, to have better cooling effect, good and fast pipe forming.

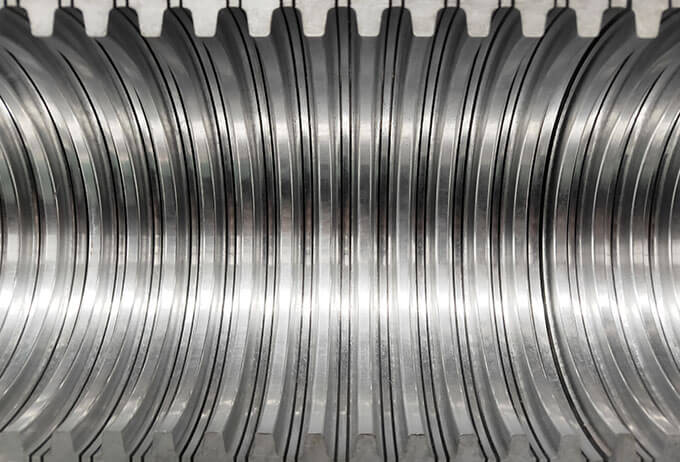

Gear rack is placed at the top of corrugated mould. All gear racks are after nitriding and heating treatment, prolonged wear resisting.

Mould is processed by CNC, ensure mould precision and mould running smoothly.