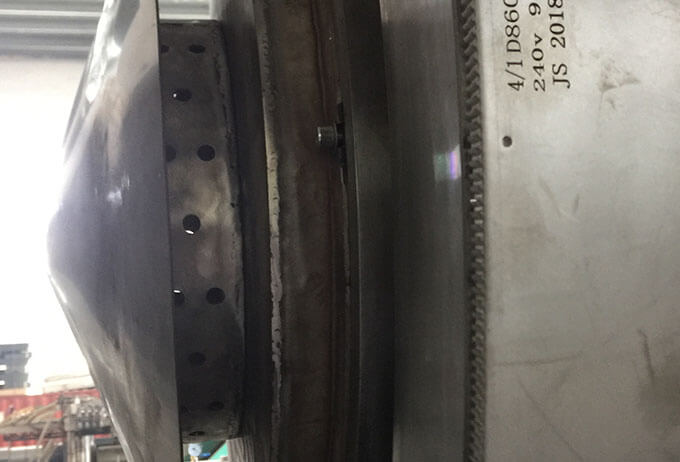

Moving Device of Die Head

For big size die head, moving device can move die head forward and back, also adjust the height of die head. Operation is fast and easy.

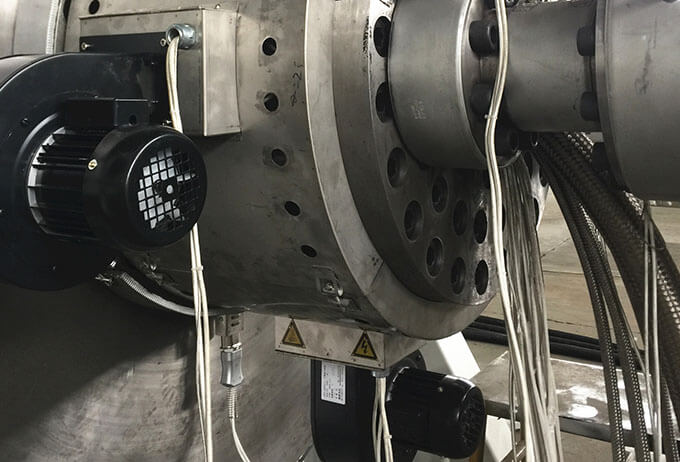

Extrusion die head apply spiral structure, each material flow channel is placed evenly. Each channel is after heat treatment and mirror polishing to ensure material flow smoothly. Die head structure is compact and also provide stable pressure, always from 19 to 20Mpa. Under this pressure, pipe quality is good and very little effect on the output capacity. Can produce single layer or multi-layer pipe.

Get a Quote

For big size die head, moving device can move die head forward and back, also adjust the height of die head. Operation is fast and easy.

For big size die head with rotary device, die head can rotate by 90 degree. When changing bush, mandrel, die head will turn 90 degree. Can use crane to lift and change bush and mandrel. This way is very convenient.

This device is added on die head to produce big and thick pipe. To exhaust heat inside the pipe and cooling pipe inside wall. The heated exhausted can be used to dry the raw material.

When produce pipe with big diameter and wall thickness, we will use cooling water or oil together with cooling fan to cool the core of die head to avoid over heating and ensure good material quality.