News

Site Editor

Site

/uploads/5cb96e23627a5.png

With the growing demand for high-performance production equipment in the plastic industry, double wall corrugated pipe equipment has become a popular choice due to its superior performance and broad application prospects. Among these systems, the cooling system is a critical component in ensuring production quality and efficiency. Water-cooled and air-cooled systems are two common cooling methods, each with distinct advantages and disadvantages, suitable for different production needs.

Site

/uploads/5cb96e23627a5.png

With the growing demand for high-performance production equipment in the plastic industry, double wall corrugated pipe equipment has become a popular choice due to its superior performance and broad application prospects. Among these systems, the cooling system is a critical component in ensuring production quality and efficiency. Water-cooled and air-cooled systems are two common cooling methods, each with distinct advantages and disadvantages, suitable for different production needs.

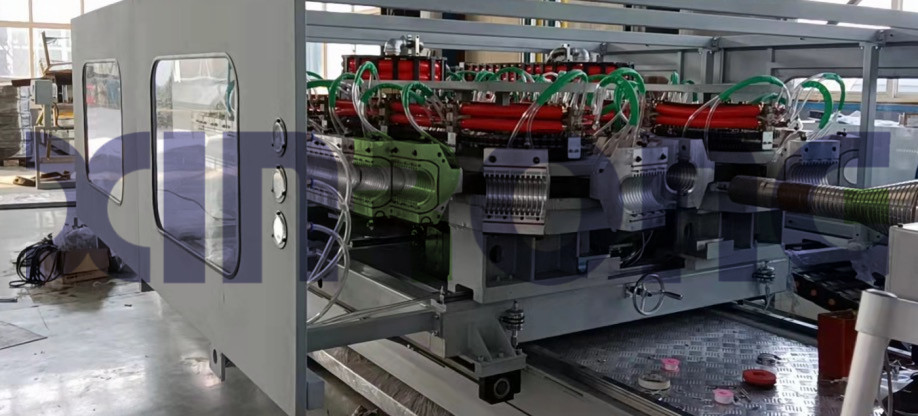

Double Wall Corrugated Pipe Equipment: Differences Between Water-Cooled and Air-Cooled Systems

Views: 586

Author: Site Editor

Publish Time: 2025-02-20

Origin: Site

With the growing demand for high-performance production equipment in the plastic industry, double wall corrugated pipe equipment has become a popular choice due to its superior performance and broad application prospects. Among these systems, the cooling system is a critical component in ensuring production quality and efficiency. Water-cooled and air-cooled systems are two common cooling methods, each with distinct advantages and disadvantages, suitable for different production needs.

Water-Cooled System: Efficient and Stable Cooling Method

The water-cooled system is a cooling method that uses water’s high heat capacity to absorb and transfer heat through circulating water. Its main advantage is its high heat dissipation capability and stable operating temperature, making it particularly suitable for equipment that requires long hours of continuous operation. Water cooling can quickly lower the temperature of the equipment, preventing overheating and potential production failures or equipment damage.

Moreover, water-cooled systems are more energy-efficient, providing better heat dissipation than air-cooled systems under similar conditions. These systems are ideal for handling high-load, high-temperature production processes, and are widely used in the production of dual wall corrugated pipes.

However, water-cooled systems do come with some challenges. Since they require a water source, water-cooled equipment typically needs to be connected to a piping system and requires the maintenance of good water quality to avoid issues such as pipe blockages or corrosion.

Air-Cooled System: Simple and Economical Choice

In contrast to water-cooled systems, the air-cooled system uses fans to blow air over the equipment surface, dissipating the heat generated. The advantage of this cooling method lies in its simplicity, easy installation, and maintenance. It does not rely on a water source, making it especially suitable for situations where water resources are limited or where space constraints are a concern.

Air-cooled systems have lower initial costs and are suitable for smaller production lines or lighter production loads. While the heat dissipation capacity of air-cooled systems is not as strong as that of water-cooled systems, they can still effectively maintain the temperature of the equipment under low-load conditions, ensuring stable operation.

However, it is important to note that air-cooled systems are more dependent on the ambient temperature. When external temperatures are high, the cooling efficiency may decrease, which could impact the operational efficiency of the equipment.

Choosing Between Water-Cooled and Air-Cooled Systems

When selecting the appropriate cooling system, companies need to consider specific production requirements, working environment, and equipment load. For larger-scale production, higher loads, and operations that require long-term stability, the water-cooled system is undoubtedly the more ideal choice. On the other hand, for smaller-scale production or situations with strict installation space limitations, the air-cooled system may be more suitable.

Both water-cooled and air-cooled systems for double wall corrugated pipe equipment have their unique advantages. With the ongoing advancement of technology, cooling systems are continually evolving to meet the diverse needs of the market. By selecting the right cooling system, companies can ensure improved production efficiency, longer equipment lifespan, and enhanced production quality.

Jiangsu Xinrongplas Machinery Co., Ltd. will continue to be committed to providing high-quality plastic pipe production equipment to global customers and help infrastructure construction and industrial development in various countries. Welcome to consult.