News

Site Editor

Site

/uploads/5cb96e23627a5.png

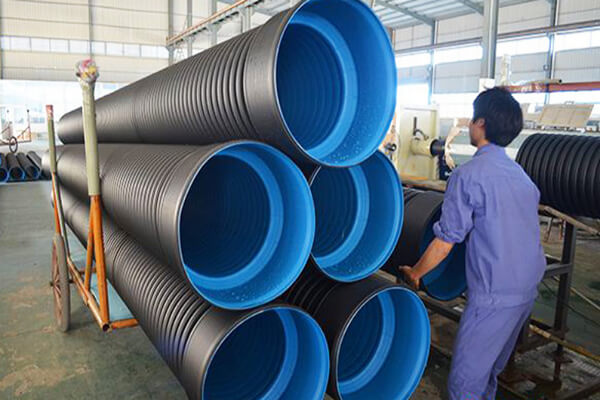

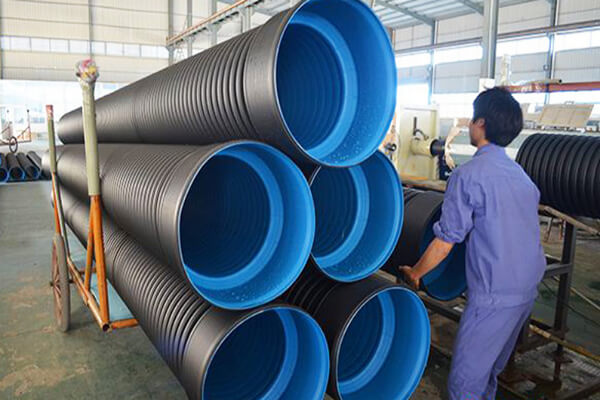

The double wall bellows, which are HDPE pipes used in the transfer of sewage and other liquid materials usually undergoes a rigorous process of manufacture. However, manufacturers insincerity usually lead to the product of double wall corrugated pipes that are of lesser quality. Despite this, there is need to work with a reliable manufacturer and supplier of double wall bellows to ensure that you are using corrugated pipes that will stand the test of time.

Site

/uploads/5cb96e23627a5.png

The double wall bellows, which are HDPE pipes used in the transfer of sewage and other liquid materials usually undergoes a rigorous process of manufacture. However, manufacturers insincerity usually lead to the product of double wall corrugated pipes that are of lesser quality. Despite this, there is need to work with a reliable manufacturer and supplier of double wall bellows to ensure that you are using corrugated pipes that will stand the test of time.

How Are Double-Wall Bellows Made?

Views: 1303

Author: Site Editor

Publish Time: 2020-02-06

Origin: Site

Double-wall corrugated pipe or bellows have been of immense importance, especially in the conveyance of water and other liquid materials from one point to another. Their high heat resistance, lightweight and durability have made double wall bellows to be one of the favourite pipes used by many companies in the transport of liquid materials. Well, the manufacturing process of double-wall bellows goes through various processes such as the double-wall corrugated pipe extrusion, and most of these processes like you would rightly guess are carried out using specially designed double-wall corrugated pipe machines.

Without much ado, let's take a quick look at some of the process and stages involved in the manufacture of double-wall bellows.

1. Bellows Design

In this stage, a piece of a metal bellows together with bellows expansion joints are fixed to a piping system which helps it to thermal growth of the pipe. During the bellows design, various cycles of heating and cooling of the piping system are involved and at each heating and cooling, the bellows are said to have undergone one complete cycle.

While the process of heating and cooling for a double wall bellows is more and frequent, a single-ply metallic bellow undergoes only a few cycles of heating and cooling since such may undergo a very few movements when used for conveying materials.

2. Forming The Bellows Tube

After the design of how and what type of bellows will be manufactured, the next stage involves making the bellows tube, and the tubes are usually corrugated. Also, in the forming stage, the outer tube is usually slightly larger than the inner tube, especially when forming multi-ply bellows. Typically, a multi-ply bellow is made up of 2-3 tubes called plies, but depending on the intended use of the bellows, there may be up to about 5 tubes (plies) or even more.

3. Forming The Bellows

In corrugating the tube, different methods can be used to achieve this, but the most common and method that is usually adopted involves the use of a mechanical dye-forming together with hydroforming. When doing this, the bellows tube is usually placed over the dye on the double wall corrugated pipe machine. While on the an, the tube is rotated so that as the dye expands and contract, there will be an even expansion over the surface of the tube without concentrating the dye or thinning over one area of the tube. After the number of convolutions that was programmed for the bellows tube is formed, this stage in the manufacture of a double wall bellows is complete.

4. Re-Rolling Process

This is a secondary stage that helps in shaping the formed metal bellows to the expected geometry as designed by the engineers. Unfortunately, this is a part in which many unscrupulous double wall bellows manufacturers skip in order to make more gains. While skipping this step, they only compress the bellows to size in a press, and this ends up reducing the durability of the finished bellows.

5. Roll Seam Welding

This is continuous process of overlapping welding on the same spot, and this process helps in joining the tubes together at the bellows neck, especially for multi-ply bellows. However, depending on how proficient a welder is, this process may or may not be required since the welder can weld the joints in such a way that there will be no leaks afterwards.

6. Expansion of the Bellows Neck To Size

At this stage, some specially designed double wall corrugated pipe machine which can help in expanding the bellows are used to make each pipe size and fit over another pipe or inside a flange. In most cases where the fits around the neck are sloppy with gaps to be filled, there is usually and increased chances of leakage.

Conclusion

The double wall bellows, which are HDPE pipes used in the transfer of sewage and other liquid materials usually undergoes a rigorous process of manufacture. However, manufacturers insincerity usually lead to the product of double wall corrugated pipes that are of lesser quality. Despite this, there is need to work with a reliable manufacturer and supplier of double wall bellows to ensure that you are using corrugated pipes that will stand the test of time.