News

Site Editor

Site

/uploads/5cb96e23627a5.png

The gas pipes commonly used in modern society are generally polyethylene gas pipes, which are generally high-density polyethylene gas pipes, which are mainly used for plastic pipes for conveying coal gas, liquefied gas and natural gas.

Site

/uploads/5cb96e23627a5.png

The gas pipes commonly used in modern society are generally polyethylene gas pipes, which are generally high-density polyethylene gas pipes, which are mainly used for plastic pipes for conveying coal gas, liquefied gas and natural gas.

Key Points of Process Operation in Polyethylene Gas Pipe Production

Views: 900

Author: Site Editor

Publish Time: 2021-12-26

Origin: Site

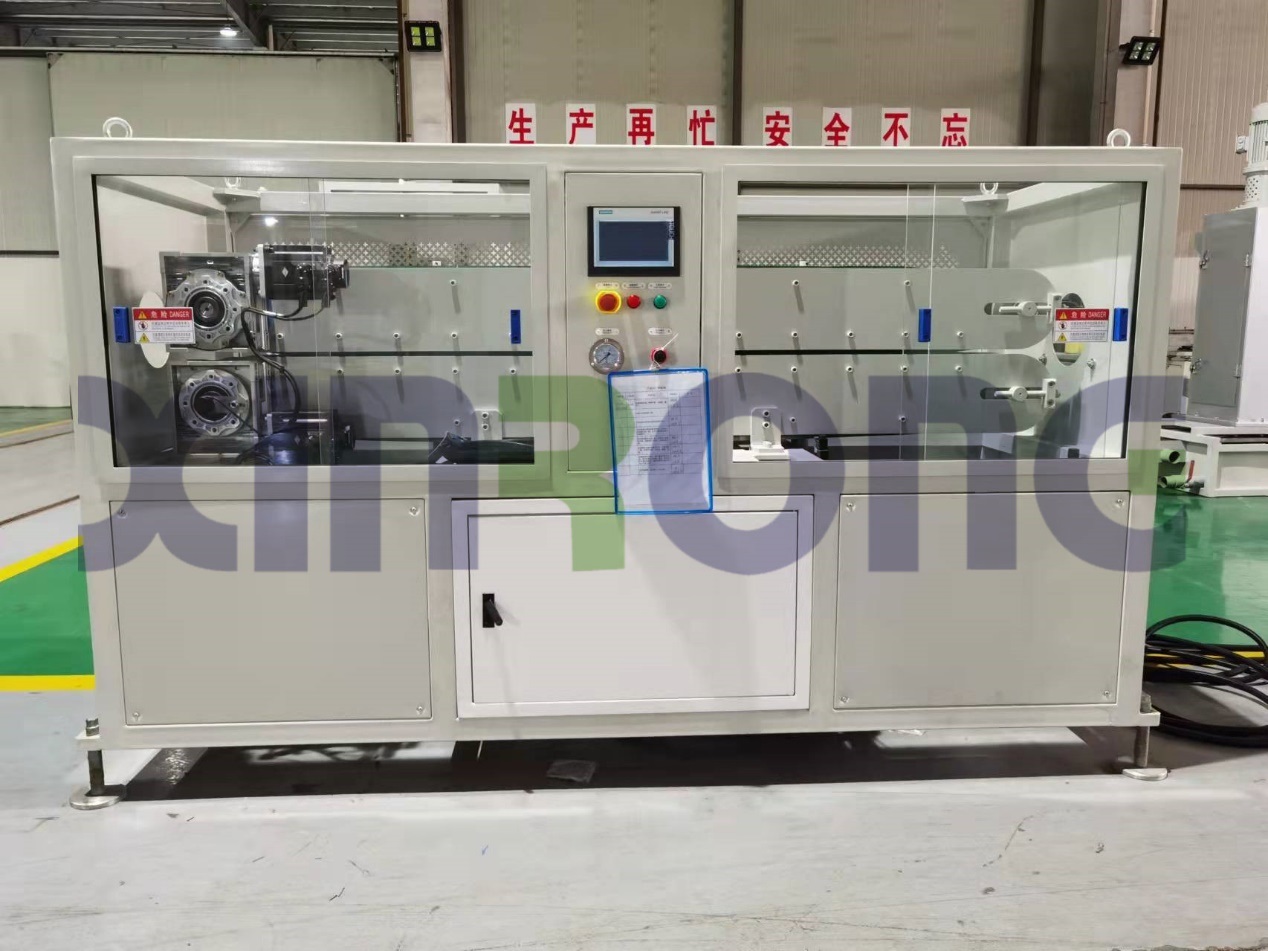

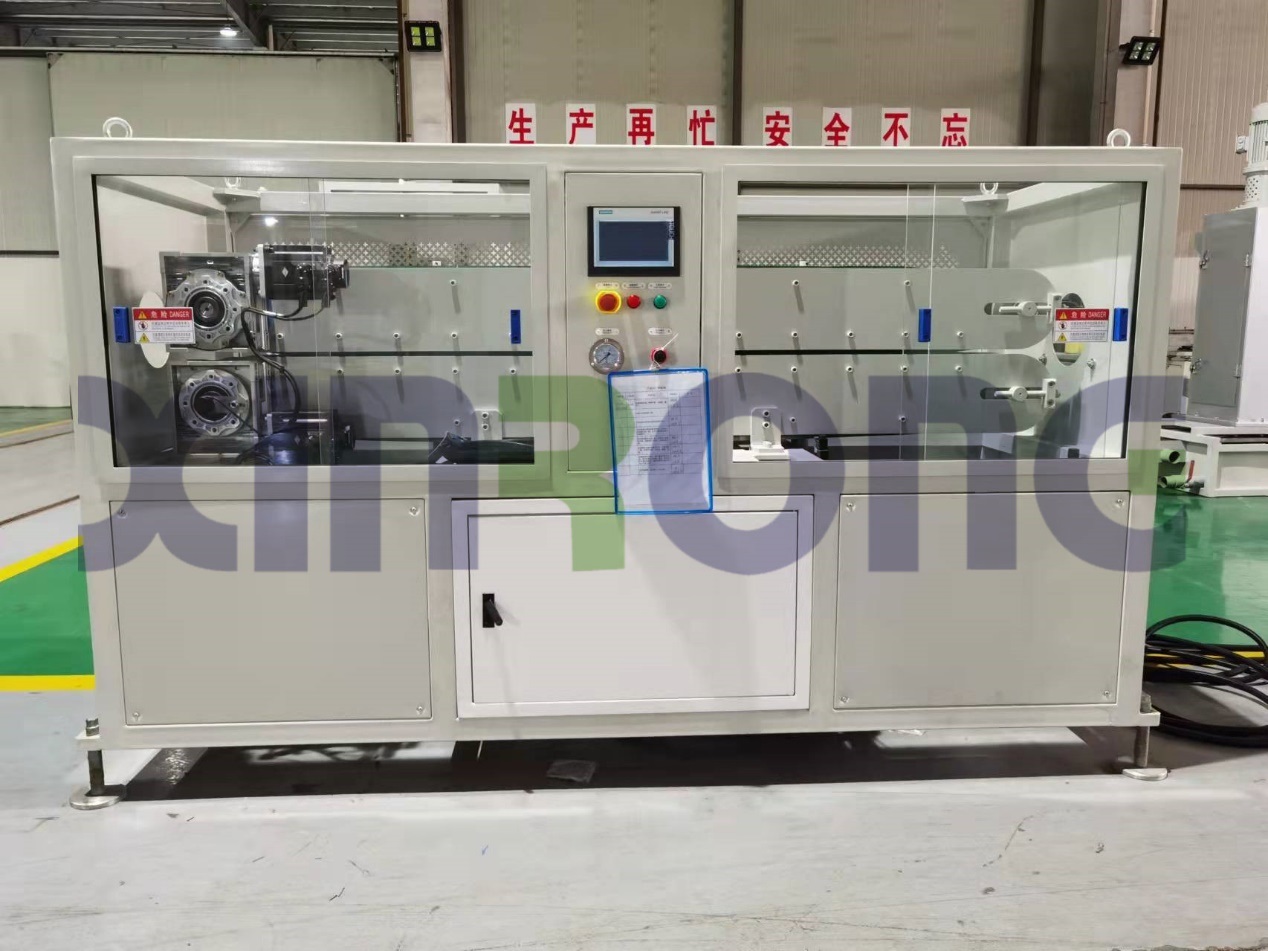

The gas pipes commonly used in modern society are generally polyethylene gas pipes, which are generally high-density polyethylene gas pipes, which are mainly used for plastic pipes for conveying coal gas, liquefied gas and natural gas. This plastic pipe has excellent low temperature resistance, chemical corrosion resistance, and good electrical insulation performance. Jiangsu Xinrongplas Machinery Co., Ltd. is an enterprise with more than 20 years of experience in the production of extruders and related auxiliary equipment. Here are some information on the key points of process operations.

1. The polyethylene gas pipe produced by the plastic extruder needs to be used in a special environment, so we sometimes add some antistatic agents and ultraviolet absorbers, which can effectively increase the service life of the pipe in a special environment.

2. In order to improve the performance of the product and reduce the production cost of the PE pipe for the polyethylene gas pipe extruded by the extruder production line, it is generally necessary to add no more than 6% light calcium carbonate or no more than 15% carbon black into the resin. , Which can be beneficial to improve the antistatic and weather resistance of the pipe.

3. The molding die structure installed on the extruder can directly select the molding die of the HDPE water pipe.

4. In order to improve the strength of HDPE gas pipe during the production process, the extruder needs to adopt a rapid cooling method after extrusion, which can make the crystallinity small and the surface of the product shiny.

Our company is professional in producing PE pipe production line and other various plastic pipe production lines. You can consult us at any time and look forward to our cooperation.