News

Site Editor

Site

/uploads/5cb96e23627a5.png

Site

/uploads/5cb96e23627a5.png

Problems of Plastic Pipe Section Deformation During Production

Views: 1541

Author: Site Editor

Publish Time: 2022-04-09

Origin: Site

The modern plastic pipe industry is mainly produced by extrusion. The plastic pipe is usually round, and different uses have certain requirements on the roundness of the pipe. When using extruder production line to produce plastic pipes, the section deformation trend is to a certain extent, but if the deformation of the deformed pipe is too large, it will affect the quality of the final product, indicating the production line has not been properly standardized.

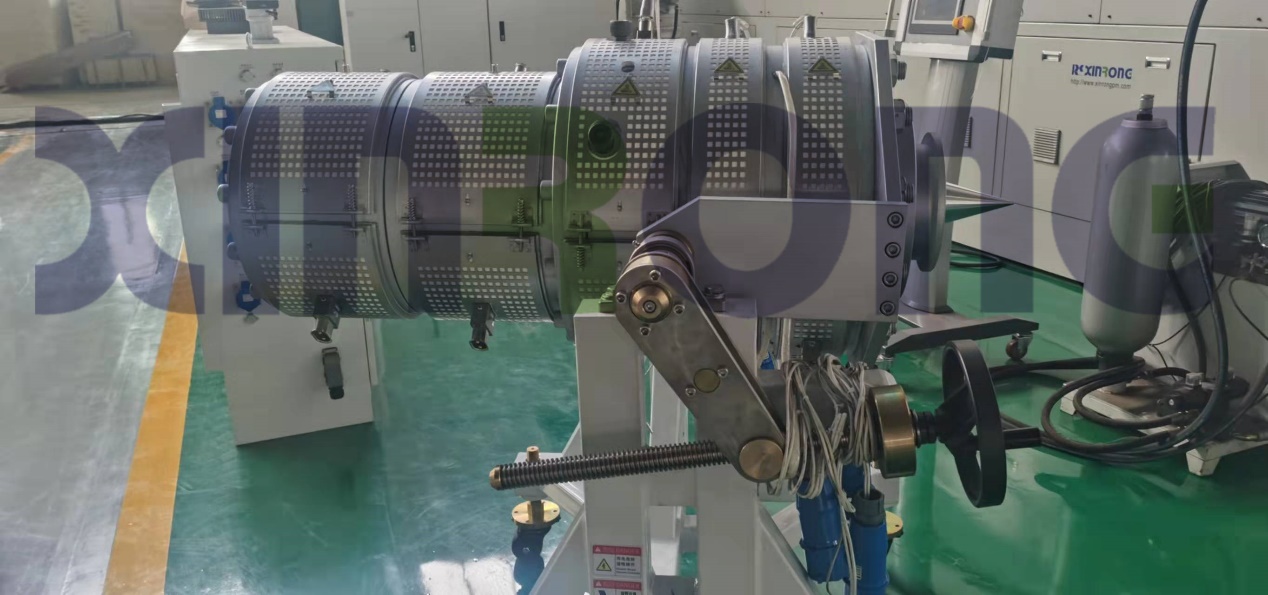

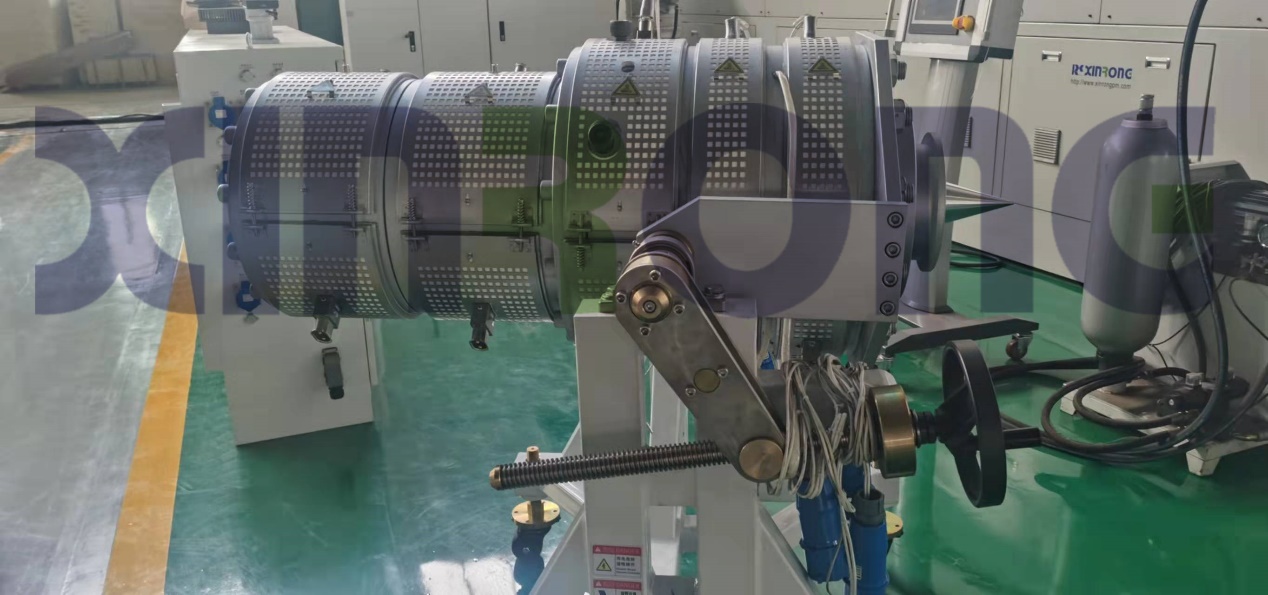

Jiangsu Xinrongplas Machinery Co., Ltd as a company with more than 25 years of experience in the production of plastic extruders and extruder production lines, we have prepared some information on normal pipe deformation for you, as follows:

1. The problem of elliptical deformation of the pipe section

The elliptical deformation of the plastic pipe indicates that the amount of deformation is very large. Generally, the degree of elliptical deformation can be determined by the degree of ellipticity. Under normal circumstances, we will analyze the cause of this problem as the larger the bending angle, the smaller the bending radius, the larger the diameter, the thinner the tube wall, and the larger the ovality generated during bending.

2. Pipe wall deformation problem

The problem of pipe wall deformation is very serious. The deformation of the pipe wall will cause the pipe wall thickness to fail to meet the pipe production requirements, which will not only affect the outer surface quality and appearance of the plastic products, but also cannot meet the actual physical properties of the pipe due to the thinning of the pipe wall. Pressure bearing capacity, if this substandard pipe is used, it may rupture during use or reduce its service life.

Simply speaking, the deformation of the tube wall is that the outer tube wall is elongated and thinned. The farther from the neutral layer, the more the tube wall is elongated, and thus the more thinned it is; the inner tube wall is shortened and thickened. We can generally solve the problem by reducing the pulling speed of the pipe or increasing the speed of the main extruder.

3. Wrinkle and deformation of the inner wall of the pipe

For example, when an extruder is used to produce a PPR pipe with a thin pipe wall, when the inner pipe wall of the pipe receives the deformation pressure, the structural strength of the pipe wall is not stable enough, so the problem of wrinkling and deformation will occur. Therefore, the thinner the wall of the pipe we produce, the worse the structural stability of the pipe, and the easier it will be to cause wrinkles and deformation.

Our company is professional in producing various plastic pipe production machines, such as PE pipe machine, PVC pipe machine, PPR pipe machine, double wall corrugated pipe machine, etc. If you have any inquries, feel free to contact us..