News

Site Editor

Site

/uploads/5cb96e23627a5.png

PVC16-63mm double cavities equipment, a single device can produce two pipes of the same diameter at the same time, greatly improving production efficiency and reducing unit energy consumption and production costs.

Site

/uploads/5cb96e23627a5.png

PVC16-63mm double cavities equipment, a single device can produce two pipes of the same diameter at the same time, greatly improving production efficiency and reducing unit energy consumption and production costs.

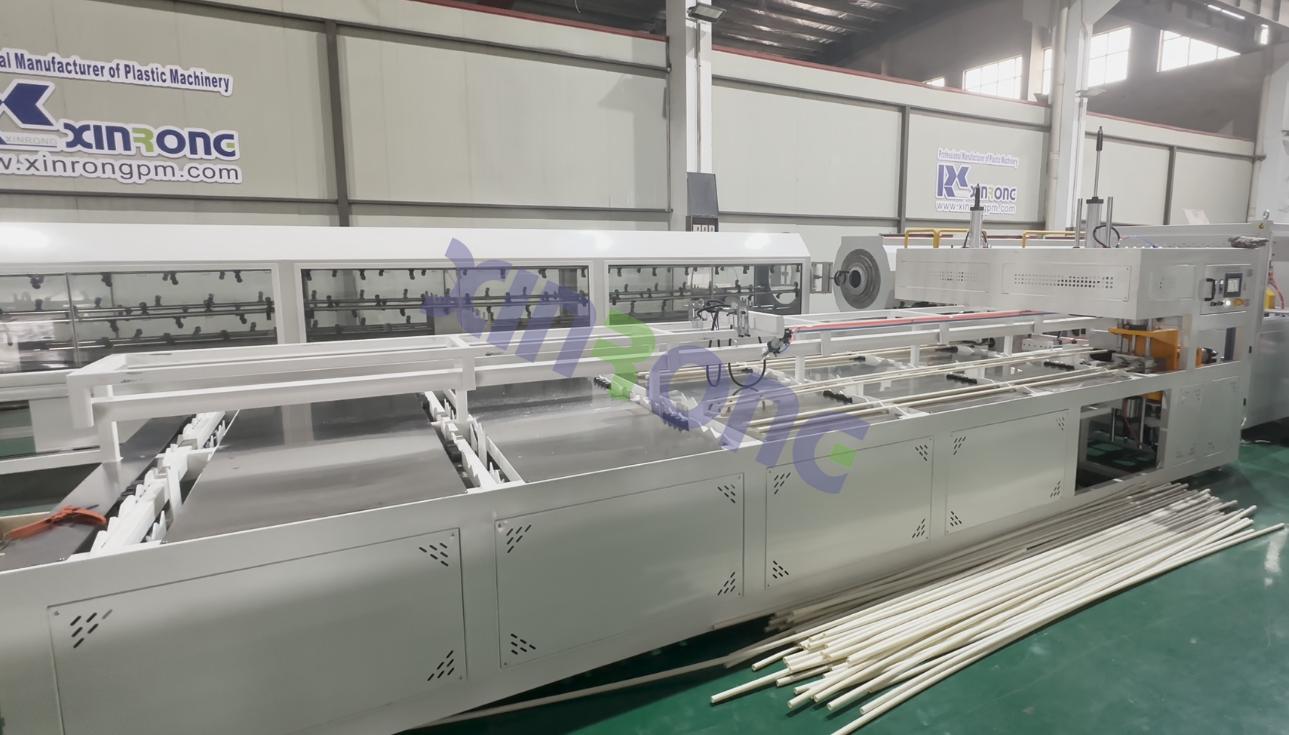

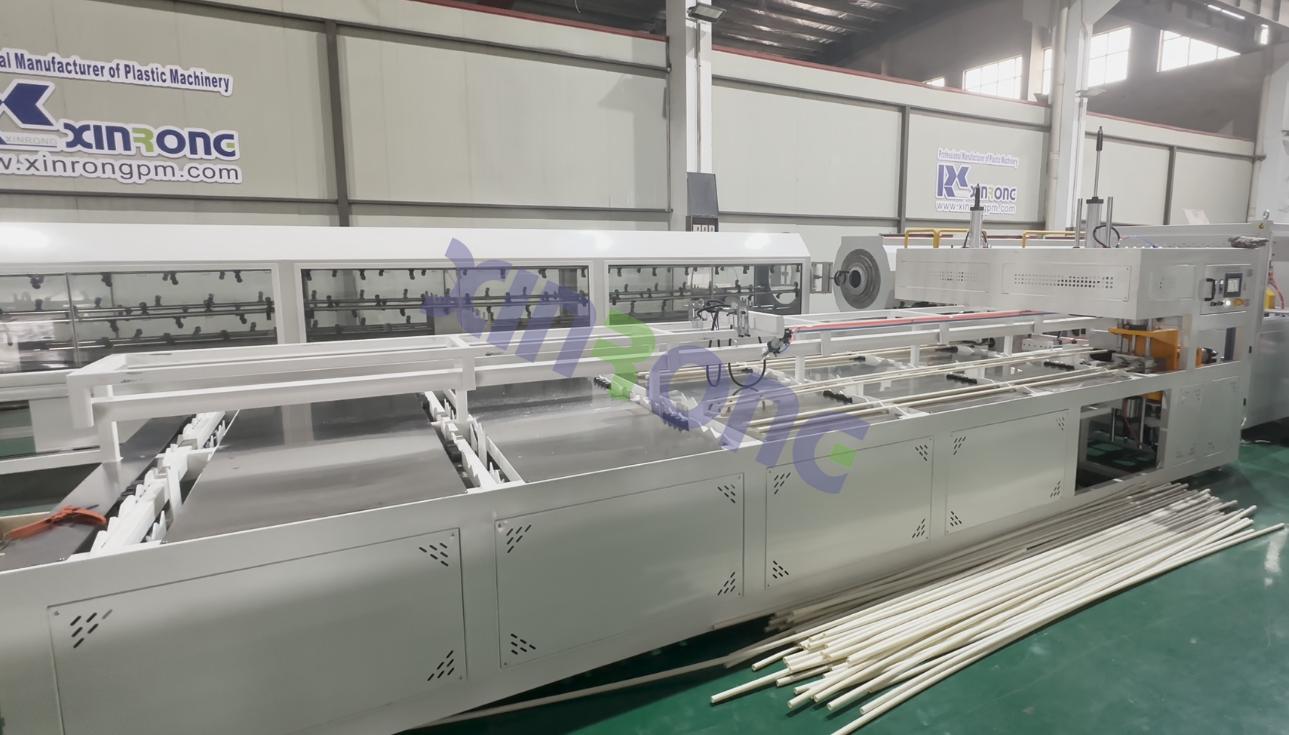

PVC16-63mm double-cavity pipe machine testing for Nigeria customer

Views: 308

Author: Site Editor

Publish Time: 2025-08-30

Origin: Site

Jiangsu Xinrongplas machinery Co., Ltd was founded in 1996,majored in all kinds of plastic pipe machine filed for 30 years. For PVC pipe machine we make diameter range from 16-1000mm. Now we have one set PVC16-63mm double cavities pipe machine testing for our Nigeria customer.

PVC16-63mm double cavities equipment, a single device can produce two pipes of the same diameter at the same time, greatly improving production efficiency and reducing unit energy consumption and production costs.

Advantages

1. High Efficiency and High Productivity: The "double cavites" design nearly doubles output compared to traditional "one cavity" equipment, maximizing productivity and return on investment.

2. Energy Saving and Cost Reduction: Sharing a single machine and control system to produce two pipes, significantly reduces energy consumption (electricity costs) and labor costs per meter of pipe.

3. Flexible and changeable: By quickly replacing molds and auxiliary machine modules, product specifications can be flexibly adjusted between Φ16-63mm to meet the diverse needs of the market.

4. Space Saving: A single production line handles the output of two lines, resulting in a compact layout and reduced factory floor space.

A complete production line mainly consists of the following systems:

Automatic feeding system SRL-Z series, to transport PVC powder from the silo to the mixer, saving time and labor, ensuring production continuity and eliminating pollution.

High-Speed Mixing System. Hot mixing ensures uniform heating and complete gelation of material, while cold mixing provides rapid cooling, preventing agglomeration and degradation, and providing high-quality dry mix for extrusion.

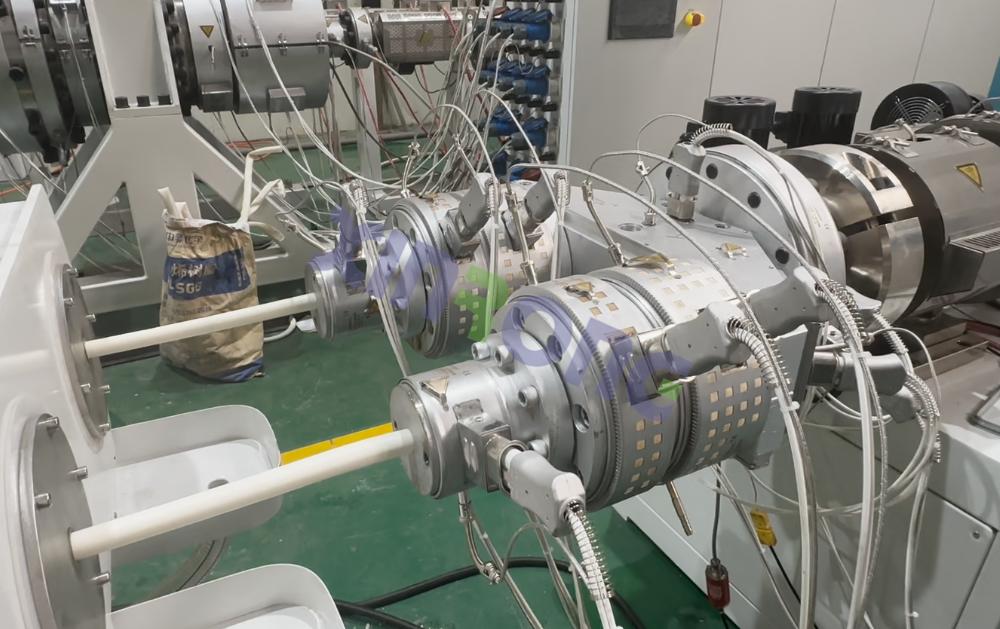

Extrusion System: SJZ-65/132 conical twin-screw extruder. This precision-engineered twin screw delivers low shear, excellent mixing, stable extrusion, and high output. Forced air cooling ensures long-term stable operation of the screw and barrel.

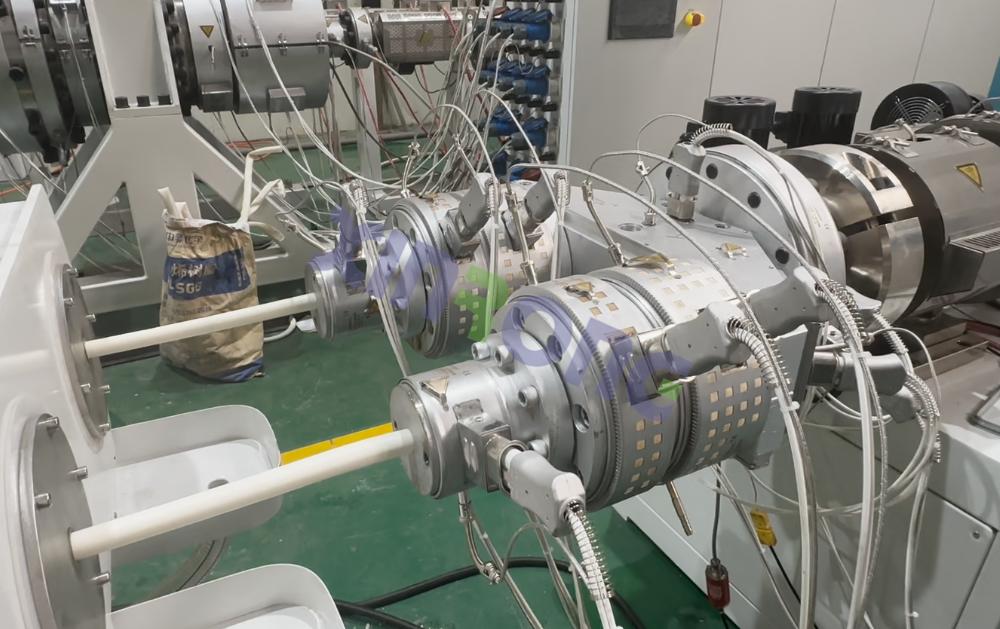

Molding System: The 16-63 double-cavities extrusion die is the core technology. The flow paths are precisely calculated to ensure the consistency of the two melt flows, pressures, and temperatures, ensuring uniform wall thickness and concentricity of the two tubes.

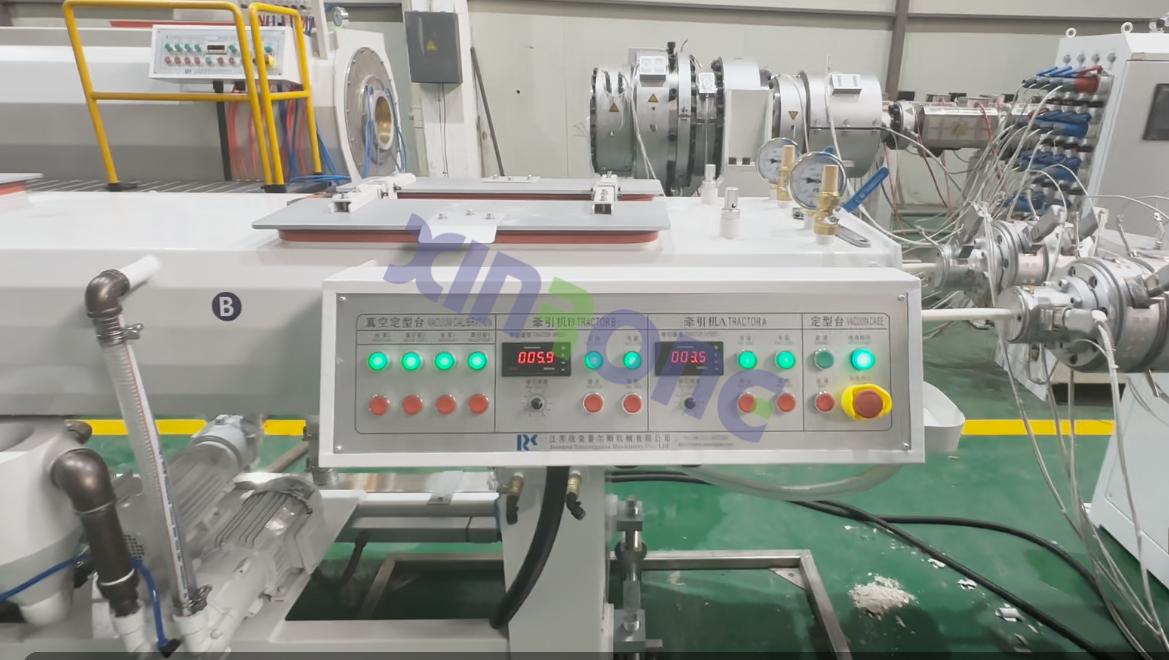

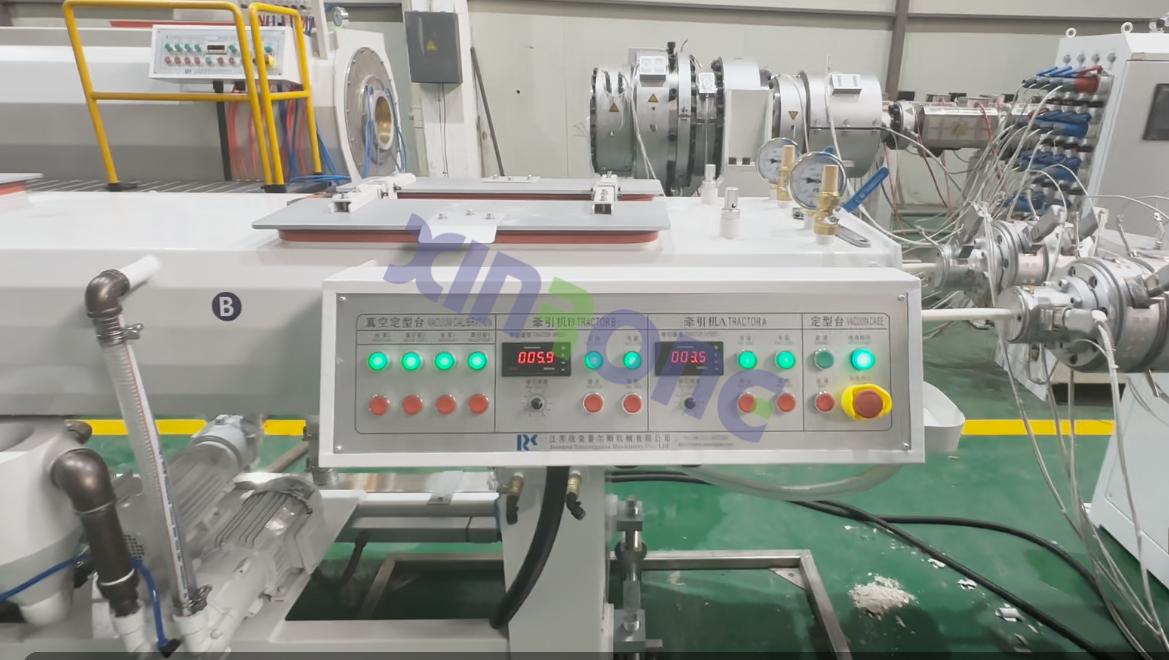

Vacuum Setting Tank: A double-chamber stainless steel vacuum tank (6m or 9m) features a dual-channel design and independent vacuum control system. It uses a spray cooling method for high cooling efficiency, ensuring rapid shaping of the pipe with good roundness and smooth inner and outer surfaces.

Haul off system, double-track tractor The powerful double-track design has independent clamping and synchronous traction functions, with large and stable traction force, which can perfectly adapt to the synchronous output of two pipes without slipping or deformation.

Cutting System: Planetary cutters (or gantry cutters) utilize a rotating planetary cutter head for smooth, burr-free cuts, making them suitable for cutting large-diameter pipes to length. CNC-controlled, they deliver precise lengths, low noise, and are dust-free.

The socket machine changes the shape of the pipe end through external force, so that the expanded pipe end can form a larger contact area with the joint.