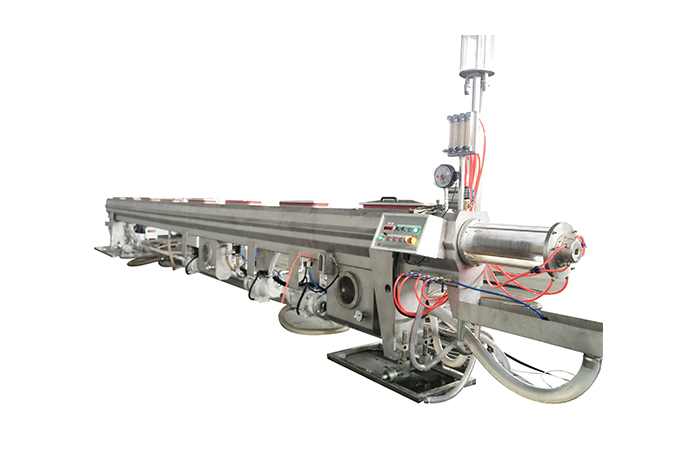

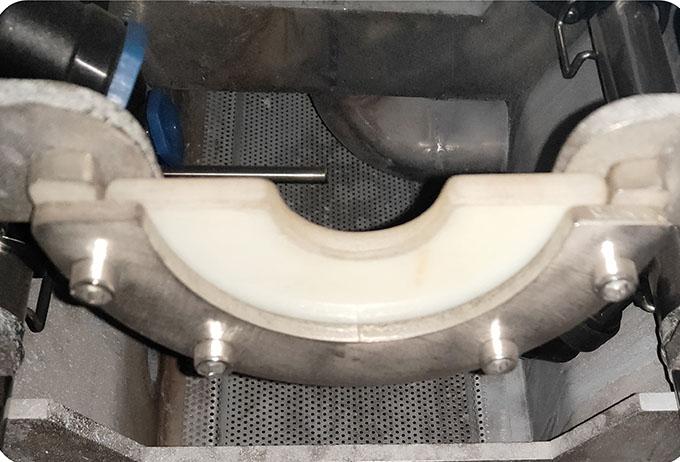

Special Design of Calibrator

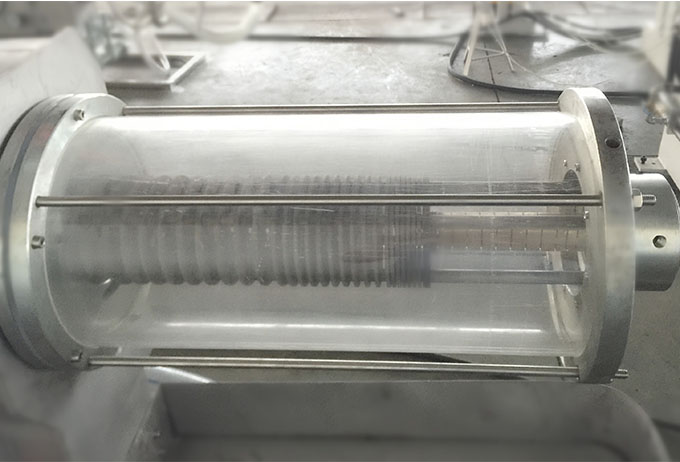

Calibrator is specially designed to make more pipe area touches with cooling water directly. This design make better cooling and forming of square pipes.

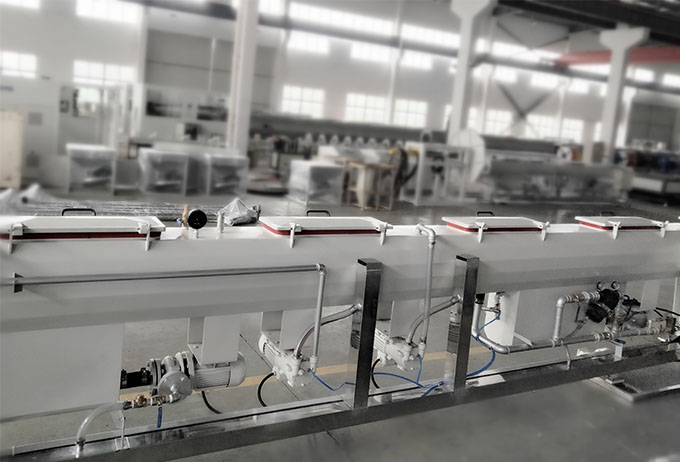

Vacuum tank is used to shape and cool pipe, so as to reach standard pipe size. We use double-chamber structure. First chamber is in short length, to ensure very strong cooling and vacuum function. As calibrator is placed in the front of first chamber and pipe shape is formed mainly by calibrator, this design can ensure quick and better forming and cooling of pipe.

Get a Quote

Calibrator is specially designed to make more pipe area touches with cooling water directly. This design make better cooling and forming of square pipes.

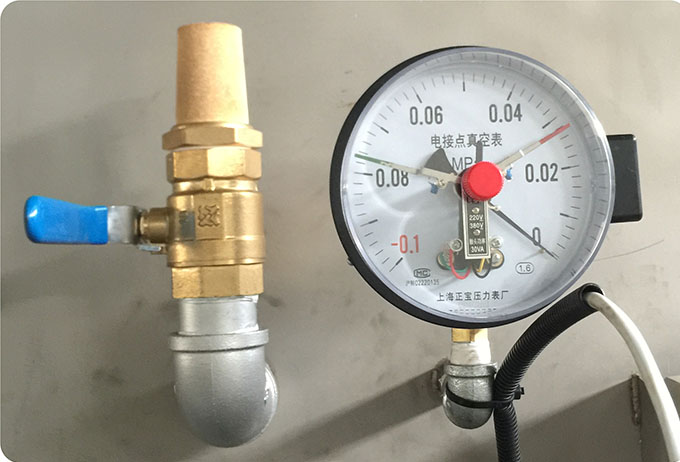

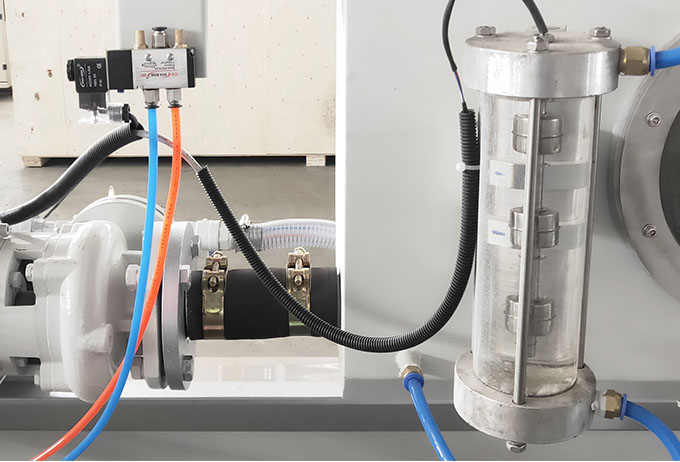

This system will control vacuum degree within set range. With inverter to control vacuum pump speed automatically, to save power and time for adjustment.

We place silencer on the vacuum adjust valve to minimize noise when air come into the vacuum tank.

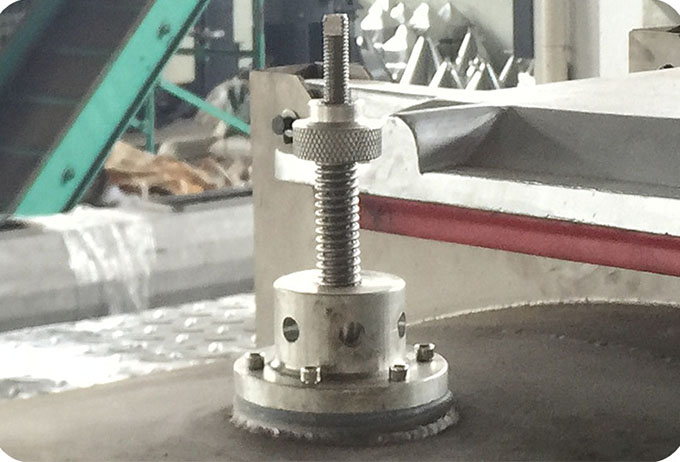

To protect the vacuum tank. When vacuum degree reach maximum limitation, the valve will open automatically to decrease vacuum degree to avoid broken of tank. Vacuum degree limitation can be adjusted.

Special designed water control system, with water continuously enter in and water pump to drain hot water out. This way can ensure low temperature of water inside chamber. Whole process is fully automatic.

To separate the gas water water. Gas exhausted from upside. Water flow into the downside.

All water drainage from vacuum tank are integrated and connected into one stainless pipeline. Only connect the integrated pipeline to outside drainage, to make operation easier and faster.

=

Half round support is processed by CNC, to ensure it can fit pipe exactly. After pipe moves out from calibration sleeve, the support will ensure pipe roundness inside vacuum tank.