Strong Cooling for Calibrator

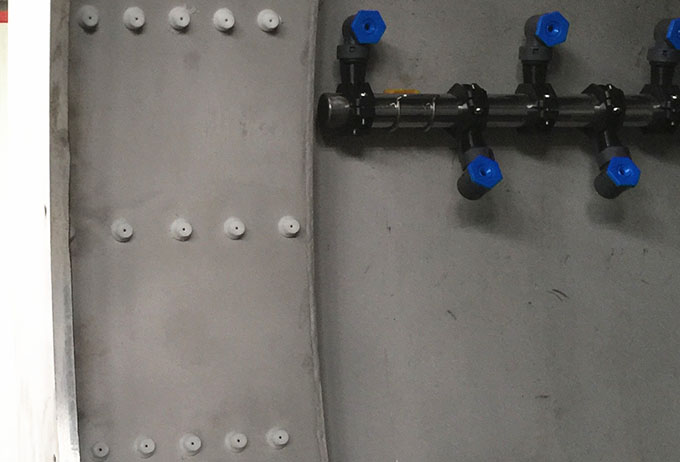

With special cooling system for calibrator, which can have better cooling effect for pipe and ensure high speed. Also with good quality spray nozzle to have better cooling effect and not easy blocked by impurities.

Vacuum tank is used to shape and cool pipe, so as to reach standard pipe size. We use double-chamber structure. First chamber is in short length, to ensure very strong cooling and vacuum function. As calibrator is placed in the front of first chamber and pipe shape is formed mainly by calibrator, this design can ensure quick and better forming and cooling of pipe.

Get a Quote

With special cooling system for calibrator, which can have better cooling effect for pipe and ensure high speed. Also with good quality spray nozzle to have better cooling effect and not easy blocked by impurities.

For big size pipe, each size have its own semicircular support plate. This structure can keep pipe roundness very well.

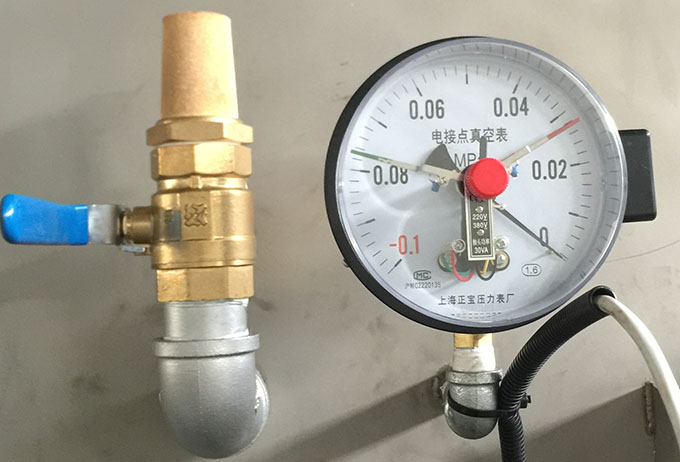

We place silencer on the vacuum adjust valve to minimize noise when air come into the vacuum tank.

To protect the vacuum tank. When vacuum degree reach maximum limitation, the valve will open automatically to decrease vacuum degree to avoid broken of tank. Vacuum degree limitation can be adjusted.

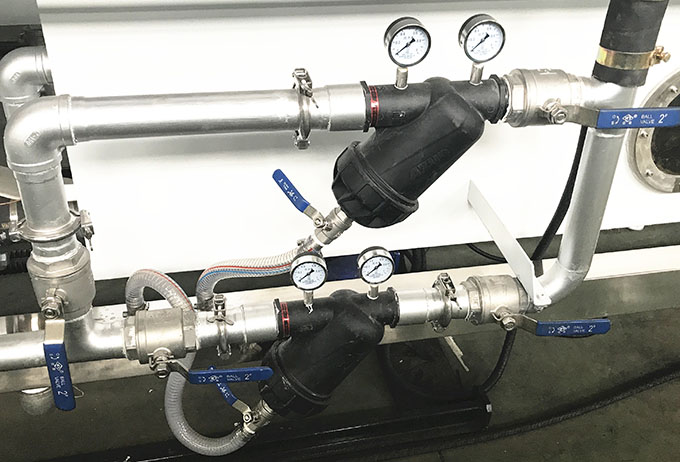

Each loop with water filtering system, to provide clean cooling water inside tank. Double loop also ensure continuous providing of cooling water inside tank.

To separate the gas water water. Gas exhausted from upside. Water flow into the downside.

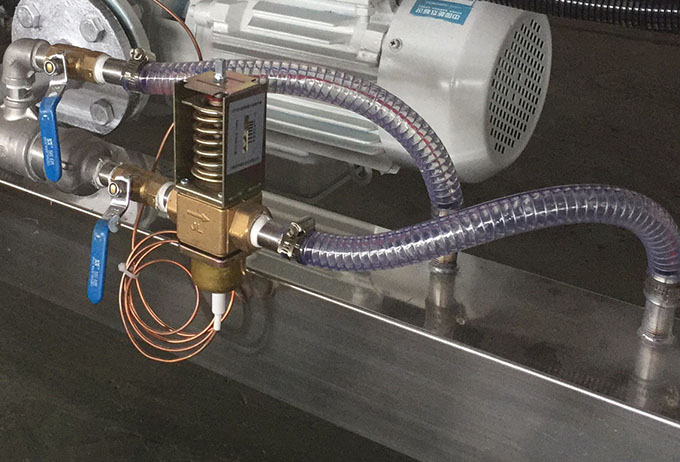

With mechanical temperature control to have accurate and stable control of water temperature.

Whole water inlet and outlet system is controlled full automatic, stable and reliable.

All water drainage from vacuum tank are integrated and connected into one stainless pipeline. Only connect the integrated pipeline to outside drainage, to make operation easier and faster.