News

Site Editor

Site

/uploads/5cb96e23627a5.png

Due to the increasing scarcity of forest resources around the world, the technical development and application of wood-plastic products at home and abroad are developing rapidly. Wood-plastic composite materials have the advantages of hardness, toughness, durability, wear resistance, and dimensional stability.

Site

/uploads/5cb96e23627a5.png

Due to the increasing scarcity of forest resources around the world, the technical development and application of wood-plastic products at home and abroad are developing rapidly. Wood-plastic composite materials have the advantages of hardness, toughness, durability, wear resistance, and dimensional stability.

Advantages and manufacturing process of WPC wood plastic composite floor

Views: 421

Author: Site Editor

Publish Time: 2024-06-25

Origin: Site

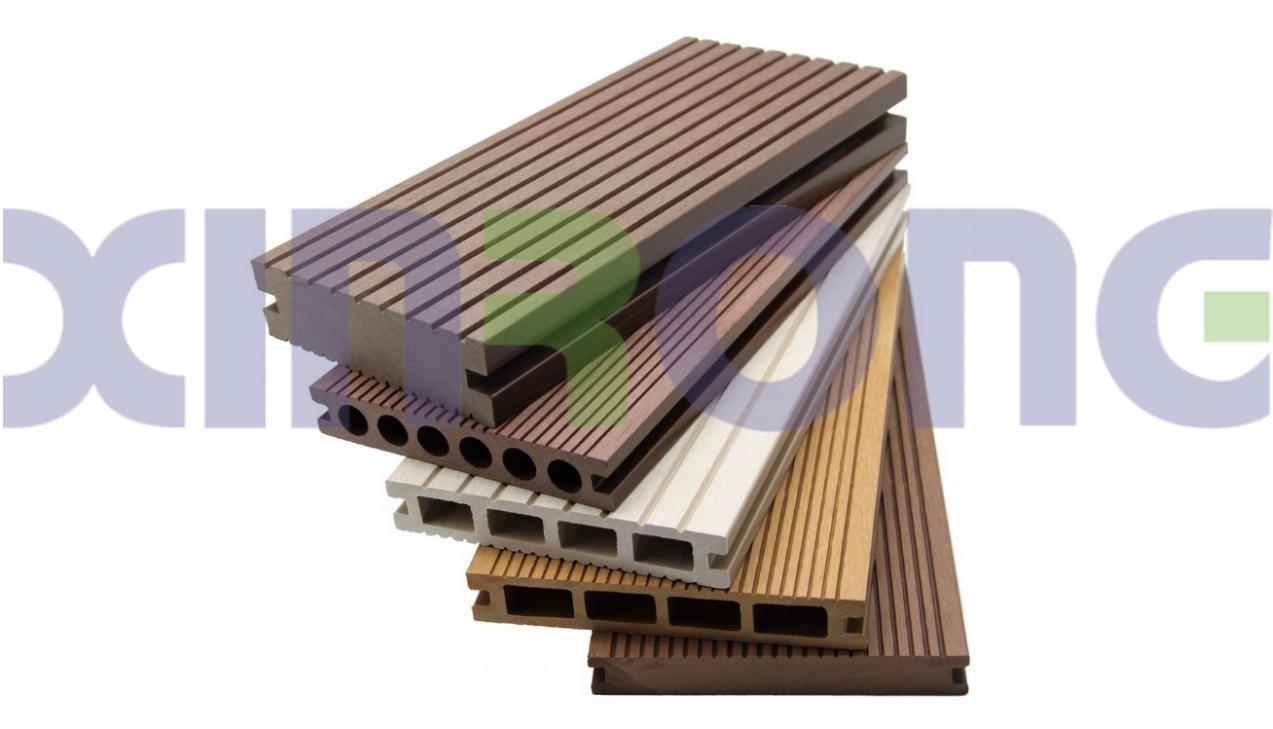

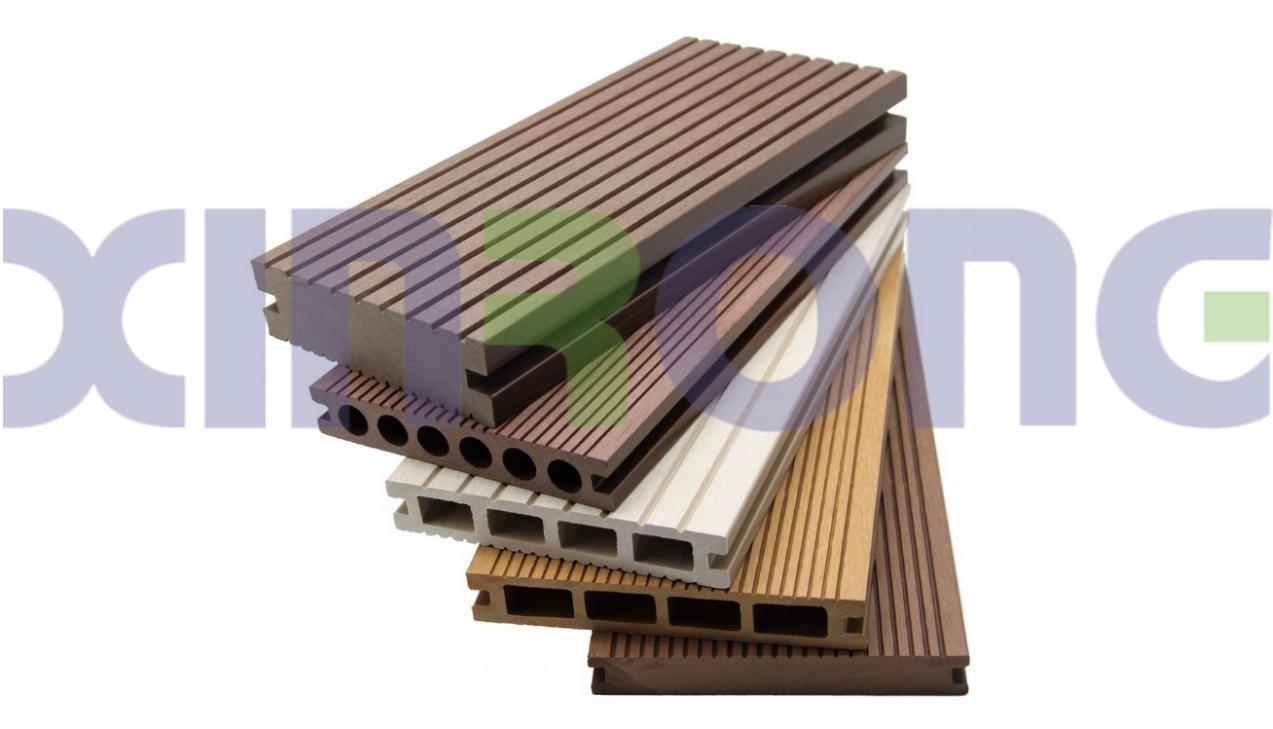

Due to the increasing scarcity of forest resources around the world, the technical development and application of wood-plastic products at home and abroad are developing rapidly. Wood-plastic composite materials have the advantages of hardness, toughness, durability, wear resistance, and dimensional stability. Generally speaking, the hardness of wood-plastic composite materials is 2 to 8 times higher than that of untreated wood, and the wear resistance is 4 to 5 times higher. The application of various additives also gives it many special properties. It is also an environmentally friendly material that can be recycled and reused, and the raw materials are cheap and abundant. It has good benefits in reducing environmental pollution, protecting forest resources, and promoting economic development, and has attracted the attention of many researchers. In addition, wood-plastic composite materials also have secondary processing properties, and the various products made are beautiful in appearance. It is one of the ideal substitutes for wood.

Extrusion processing is one of the important molding methods for modified plastics. The performance of the processing object must be involved in the extrusion process. The performance of the processed material not only plays a decisive role in the performance of the product, but also has a great influence on the extrusion quality and output. Therefore, it is of great practical significance to study the relationship between the performance of modified plastics and the extrusion process. The extrusion process of wood-plastic composite extrusion technology is very complicated, with many influencing factors. The combined effect of process, formula and mold causes uncertainty between variables. The key issues of wood-plastic composite extrusion technology are: ① raw material selection (such as the variety of wood powder) and how to improve the interface bonding between the plastic matrix and the wood powder; ② molding equipment and molding process selection ③ molding mold design.

Jiangsu Xinrongplas Machinery Co., Ltd. has been engaged in plastic extrusion recycling equipment for 27 years, if you are interested in our products, please contact us!