News

Site Editor

Site

/uploads/5cb96e23627a5.png

PVC-U, PVC-O are two different types of polyvinyl chloride (PVC) pipes, which have different manufacturing processes, performance characteristics and application fields. This article will provide a detailed introduction to the differences between these two pipes.

Site

/uploads/5cb96e23627a5.png

PVC-U, PVC-O are two different types of polyvinyl chloride (PVC) pipes, which have different manufacturing processes, performance characteristics and application fields. This article will provide a detailed introduction to the differences between these two pipes.

The difference between PVC-U, PVC-O pipes

Views: 1589

Author: Site Editor

Publish Time: 2024-06-07

Origin: Site

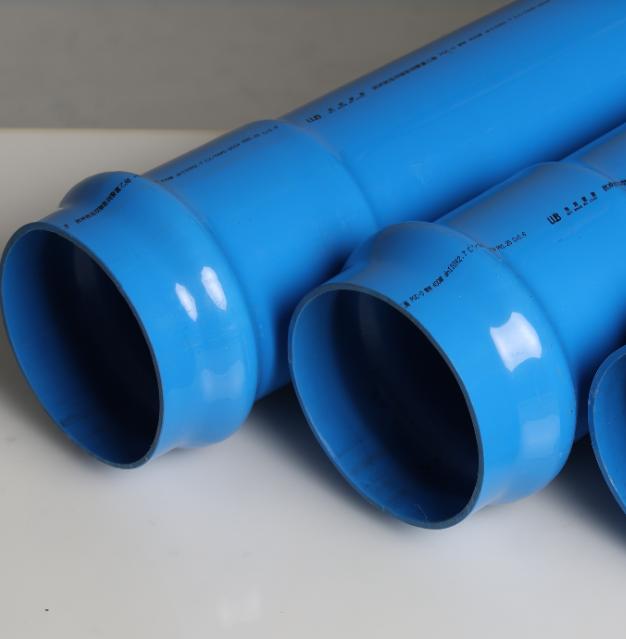

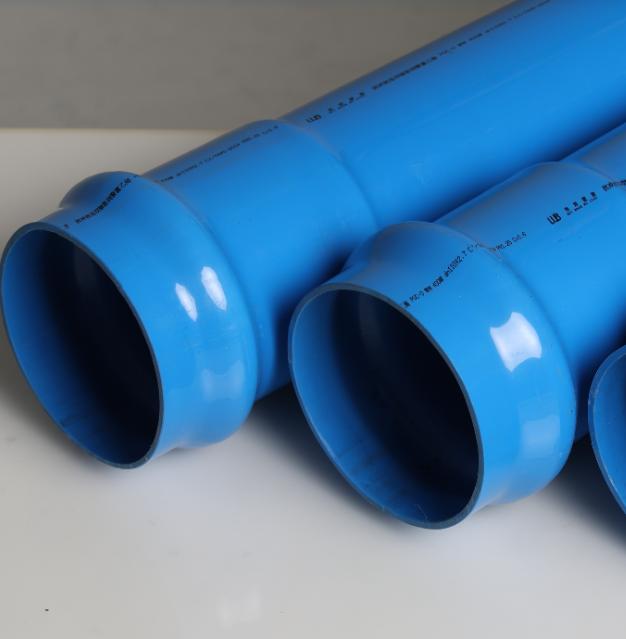

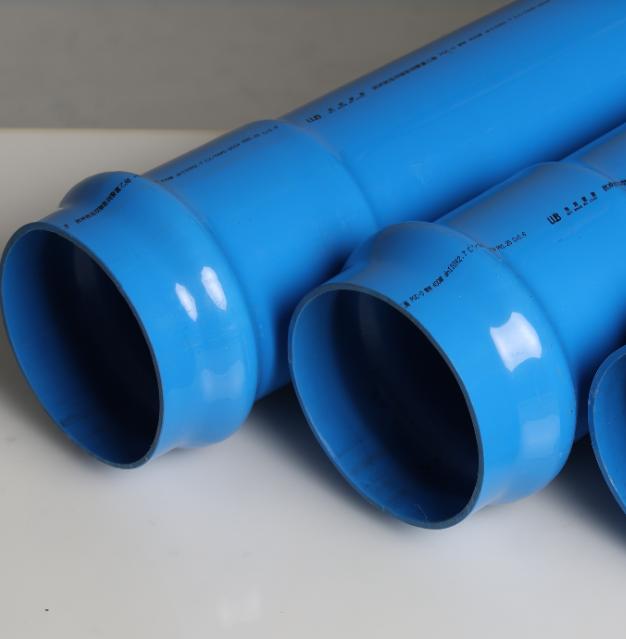

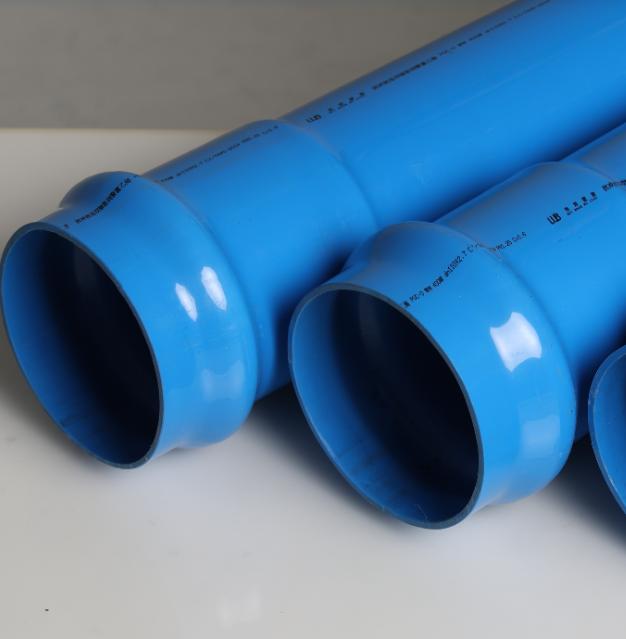

PVC-U pipe |

|  PVC-O pipe |

PVC-U, PVC-O are two different types of polyvinyl chloride (PVC) pipes, which have different manufacturing processes, performance characteristics and application fields. This article will provide a detailed introduction to the differences between these two pipes.

PVC-U pipes

PVC-U (Unplasticized Polyvinyl Chloride) is an unplasticized polyvinyl chloride pipe, which is currently the most widely used type of PVC pipe in the market. PVC-U pipes are made by adding an appropriate amount of stabilizer, lubricant, filler and other auxiliary materials to PVC resin, and through mixing, plasticizing, extrusion, shaping, cooling, cutting and other processes. PVC-U pipes have the following characteristics:

1. Good physical and mechanical properties: PVC-U pipes have high tensile strength, compressive strength, and hardness, and can withstand large internal and external pressures.

2. Corrosion resistance: PVC-U pipes have excellent acid resistance, alkali resistance, salt resistance, oil resistance, and corrosion resistance, suitable for various chemical corrosion environments.

3. Good electrical insulation performance: PVC-U pipes have high electrical insulation performance and can be used for cable protection pipes, electrical accessories, etc.

4. Good wear resistance: PVC-U pipes have good wear resistance

5. Good welding performance: PVC-U pipes can be connected using methods such as hot melt welding and electric fusion welding, with high welding strength and good sealing performance.

6. Good flame retardant performance: PVC-U pipes have self extinguishing properties, are not easy to burn, and can be used in places with high fire protection requirements.

PVC-U pipes are widely used in fields such as water supply and drainage, sewage, rainwater drainage, ventilation, cable protection, and industrial pipelines.

PVC-O pipes

PVC-O (Oriented Polyvinyl Chloride) is a PVC pipe that has undergone directional modification, also known as biaxially stretched PVC pipe. PVC-O pipes are based on PVC-U pipes, and through a special directional stretching process, the pipes undergo biaxial stretching during production, thereby improving their performance. PVC-O pipes have the following characteristics:

1. High strength: PVC-O pipes have higher tensile strength, compressive strength, and impact resistance than PVC-U pipes, and can withstand higher internal and external pressures.

2. High toughness: The toughness of PVC-O pipes is much higher than that of PVC-U pipes, with good fatigue resistance and strong resistance to stress cracking.

3. Good corrosion resistance: PVC-O pipes have the same corrosion resistance as PVC-U pipes.

4. Good wear resistance: PVC-O pipes have better wear resistance than PVC-U pipes and are suitable for conveying abrasive and granular materials.

5. Good welding performance: PVC-O pipes can be connected using the same welding method as PVC-U pipes.

6. Lightweight and efficient: PVC-O pipes are lightweight, easy to install and construct, and have low transportation costs.

PVC-O pipes are mainly used in fields such as municipal water supply, drainage, industrial water use, and agricultural irrigation.

PVC-U and PVC-O pipes have different manufacturing processes, performance characteristics, and application fields. PVC-U pipe is the most common PVC pipe, which has good physical and mechanical properties, corrosion resistance, electrical insulation performance, etc; PVC-O pipes are PVC pipes that have undergone directional modification, with characteristics such as high strength, high toughness, lightweight, and high efficiency; When selecting PVC pipes, the appropriate type of pipe should be selected based on the specific usage environment and performance requirements.

With over 29 years professional experience of plastic extrusion industry,Jiangsu Xinrongplas machinery Co.,ltd always regards providing customers with high-quality machinery and high-level services as our top priority. For PVC pipe machine, we can make the diameter range from 16-1200mm; for PVC-O pipe machine we make diameter range from 90-630mm.

Welcome to contact us if you have any plastic pipe machine inquiry!