News

Site Editor

Site

/uploads/5cb96e23627a5.png

After the pipe is extruded from the sizing sleeve, the temperature is still very high. In order to ensure the accuracy requirements of pipeline size and shape, as well as good surface work quality, it is necessary to take measures such as cooling and sizing sleeves.

Site

/uploads/5cb96e23627a5.png

After the pipe is extruded from the sizing sleeve, the temperature is still very high. In order to ensure the accuracy requirements of pipeline size and shape, as well as good surface work quality, it is necessary to take measures such as cooling and sizing sleeves.

Brief Introduction of Pipe Calibrating Method

Views: 1588

Author: Site Editor

Publish Time: 2023-04-15

Origin: Site

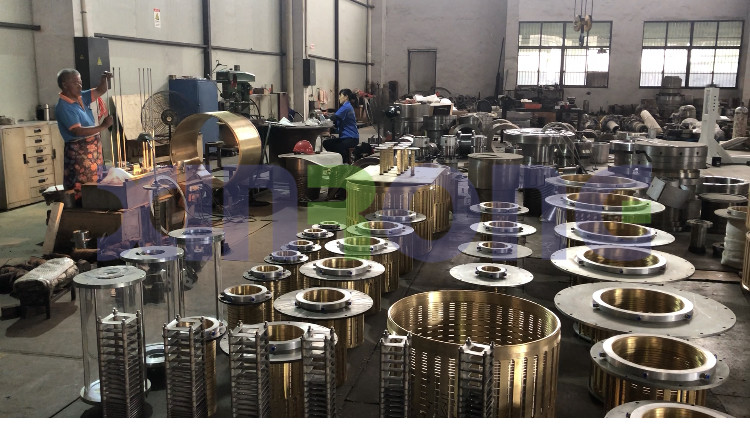

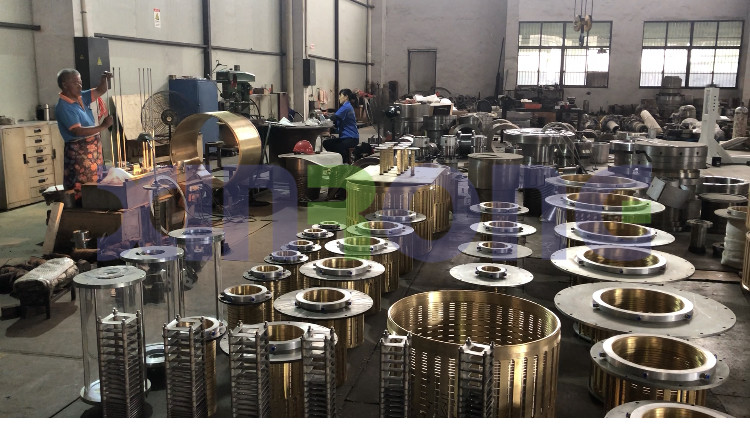

After the pipe is extruded from the sizing sleeve, the temperature is still very high. In order to ensure the accuracy requirements of pipeline size and shape, as well as good surface work quality, it is necessary to take measures such as cooling and sizing sleeves. The purpose of the calibrating sleeve is to ensure that the outer diameter or inner diameter of the pipeline reaches the specified dimensional tolerance range, and to obtain a good surface after cooling the calibrating sleeve.

There are two calibrating methods: inner diameter and outer diameter, and the commonly used method in China's plastic pipe industry standard is the outer diameter calibrating method.

Outer diameter calibrating method: The outer diameter calibrating method is suitable for straight and microporous wheel heads. It can be divided into internal pressure outer diameter calibrating and vacuum adsorption outer diameter calibrating.

Internal pressure method for outer diameter calibrating: During operation, compressed air is introduced into the plastic pipe to form a certain internal pressure, allowing the hot plastic pipe to press against the inner wall of the calibrating sleeve under the action of compressed air. To prevent compressed air leakage, plugs can be used to prevent air leakage. The characteristic of this method is its good calibrating effect, which is suitable for large diameter pipelines.

Inner diameter calibrating method: The inner diameter calibrating method is applicable to a right angle and side head. The characteristic of this method is that it can ensure the roundness of the holes in the system and the accuracy of the inner diameter of the pipes, making operation more convenient. This is because various pipes and calibrating sleeves are directly shaped through contact and cooling.

Size of calibrating sleeve: The calibrating sleeve is a key component of the calibrating device, which directly affects the quality of the calibrating tube. The dimensions of the sleeve include inner diameter and length. Different calculation methods lead to different calculation methods.

The inner diameter of the calibrating sleeve should be 0.8% -1.2% larger than the outer diameter of the pipe or 2% - 4% larger than the inner diameter used in the mold. The length of the sizing sleeve mainly depends on the type of plastic, the size of the pipeline, the extrusion processing speed, the effectiveness of the cooling system, and thermal conductivity. If the pipe diameter is greater than 100mm, the length of the sizing sleeve should be shorter, usually 3 to 5 times the outer diameter of a pipeline.

Jiangsu Xinrongplas Machinery Co.,Ltd focus on manufacturing various plastic pipe extrusion machine such as PPR pipe extrusion machine, PVC pipe extrusion machine, PE pipe extrusion machine etc, welcome to consult.