News

Site Editor

Site

/uploads/5cb96e23627a5.png

There are many auxiliary machines for plastic extruders to extrude pipes, among which the more important auxiliary machines are cooling water tanks. The auxiliary machine we use in the extruder production line is a kind of plastic auxiliary machine often used in extruding plastic pipes. We generally use steel plate welding combination for water tanks, and steel pipes are connected to form the water supply and the water supply. Through the cooling water, the entire cooling water tank can move back and forth along the running centerline of the pipe.

Site

/uploads/5cb96e23627a5.png

There are many auxiliary machines for plastic extruders to extrude pipes, among which the more important auxiliary machines are cooling water tanks. The auxiliary machine we use in the extruder production line is a kind of plastic auxiliary machine often used in extruding plastic pipes. We generally use steel plate welding combination for water tanks, and steel pipes are connected to form the water supply and the water supply. Through the cooling water, the entire cooling water tank can move back and forth along the running centerline of the pipe.

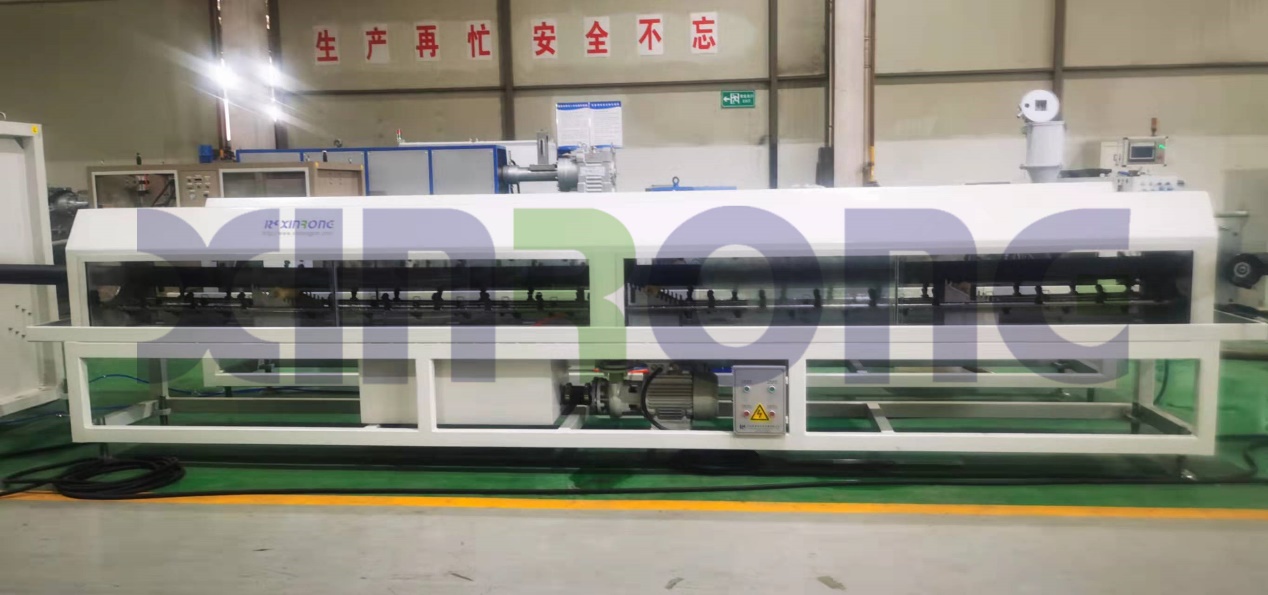

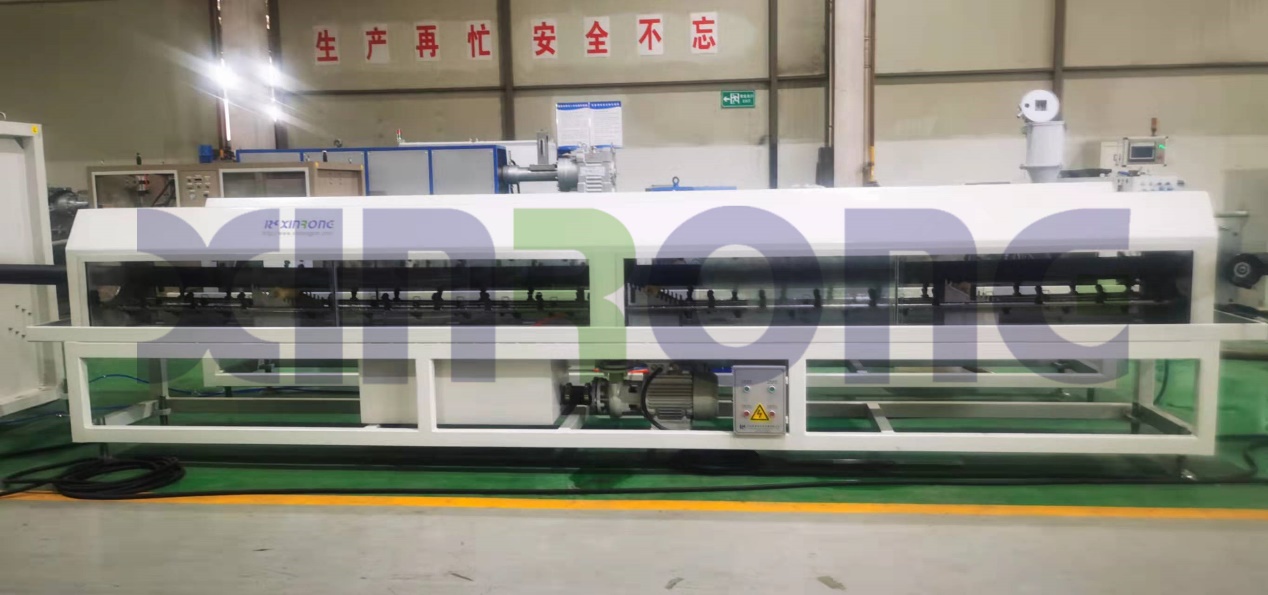

Cooling Tank for Plastic Pipe Forming

Views: 1411

Author: Site Editor

Publish Time: 2021-11-28

Origin: Site

There are many auxiliary machines for plastic extruders to extrude pipes, among which the more important auxiliary machines are cooling water tanks. The auxiliary machine we use in the extruder production line is a kind of plastic auxiliary machine often used in extruding plastic pipes. We generally use steel plate welding combination for water tanks, and steel pipes are connected to form the water supply and the water supply. Through the cooling water, the entire cooling water tank can move back and forth along the running centerline of the pipe.

The cooling water tank equipment installed after the extrusion equipment of the extruder is after the shaping sleeve. It mainly immerses the molded tube extruded by the shaping sleeve in water to further cool, solidify and shape the pipe. For the cooling of the pipe produced by the extruder with a large diameter (generally more than φ100mm), if the pipe is immersed in water with high buoyancy, the pipe will be unevenly cooled and easily bent. Therefore, we should adopt the spray method in the production of such large diameter cooling, spray cooling water on the circumference of the pipe at the same time, so that the pipe can be uniformly cooled.

Jiangsu Xinrongplas Machinery Co., Ltd. has 25 years of experience in the production of plastic extruders and related auxiliary equipment. We recommend that you need to pay attention to some matters when using this equipment, as follows:

1. The cooling water in the water tank should enter from the water outlet end of the pipe and be discharged from the water inlet end of the pipe, so that the temperature of the tube blank is gradually reduced from high temperature to low temperature, so as to prevent the sudden cooling of the pipe from causing great stress on the product and affecting the pipe. quality.

2. On-site operators must pay attention to adjusting the inlet and outlet control center line on the sink and the mold center line on the same horizontal center line, which can effectively prevent the tube from bending.

3. When we stop production, in order to ensure the service life of the cooling water tank equipment, we need to drain the cooling water in the water tank.

Our company is professional in manufacturing various plastic pipe extrusion lines. If necessary, you can consult relevant content at any time and look forward to our cooperation.