News

Site Editor

Site

/uploads/5cb96e23627a5.png

The most common defects in PE pipe production include: ovality exceeding standards, surface scratches, raised/sunken lines, patterned outer walls, slanted cuts, uneven

Site

/uploads/5cb96e23627a5.png

The most common defects in PE pipe production include: ovality exceeding standards, surface scratches, raised/sunken lines, patterned outer walls, slanted cuts, uneven

How to Solve PE Pipe Quality Problems

Views: 363

Author: Site Editor

Publish Time: 2025-07-19

Origin: Site

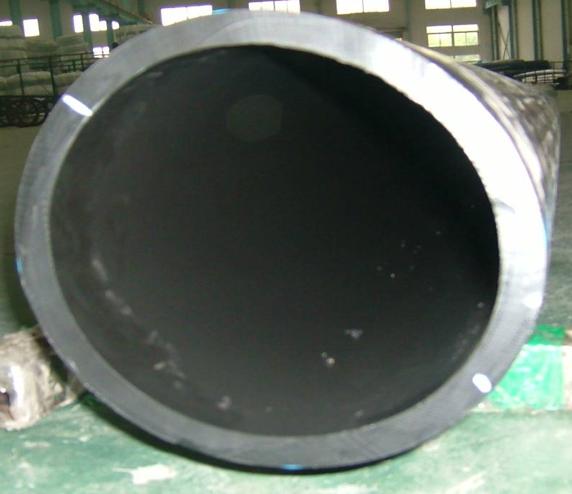

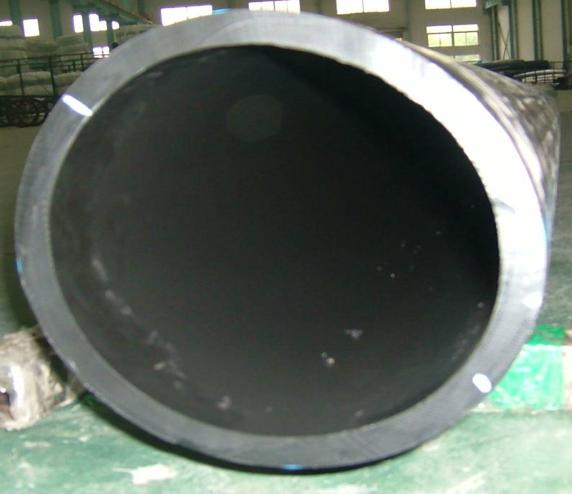

The most common defects in PE pipe production include: ovality exceeding standards, surface scratches, raised/sunken lines, patterned outer walls, slanted cuts, uneven wall thickness, pitting on the outer surface, inconsistent color stripe thickness, oversized/undersized outer diameter, circular spots, lack of gloss, glossy outer walls, inconsistent pipe lengths, bubbles on the inner wall, water ripple patterns, material breakage, bulging, etc. This article explains solutions to these PE pipe production issues.

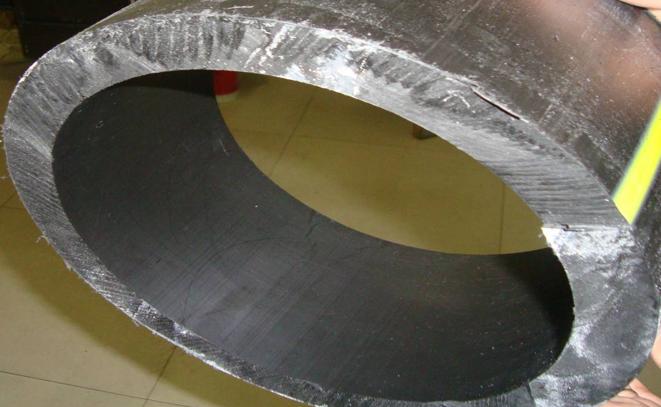

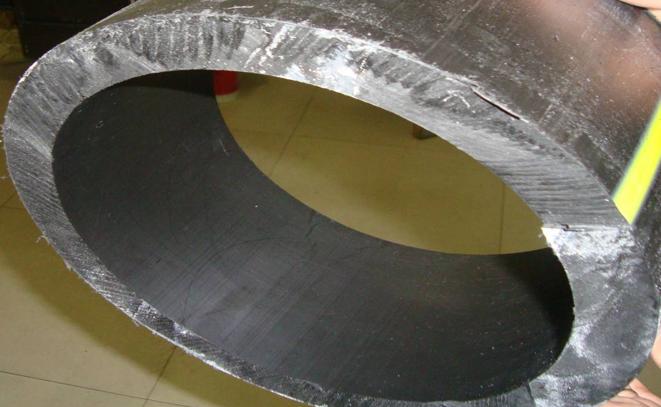

Excessive Ovality of PE Pipes

Reason | Solution |

Insufficient vacuum | Increase vacuum level |

Inadequate cooling | Reduce haul-off speed

OR lower vacuum tank water temperature

OR check for clogged nozzles |

Pipe flattening by haul-off unit | Adjust haul-off unit air pressure to meet production specifications |

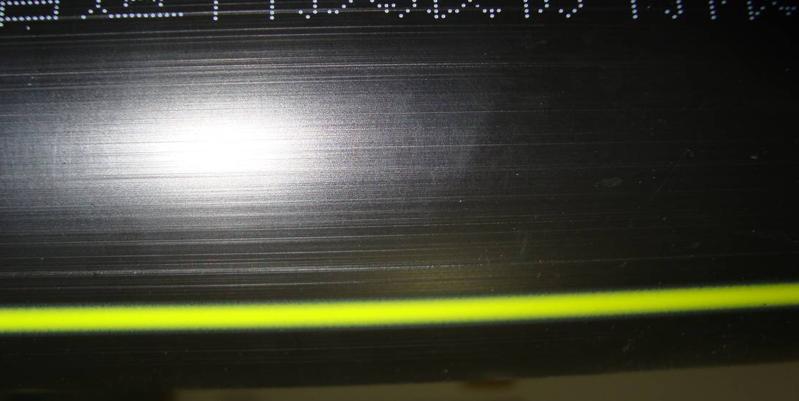

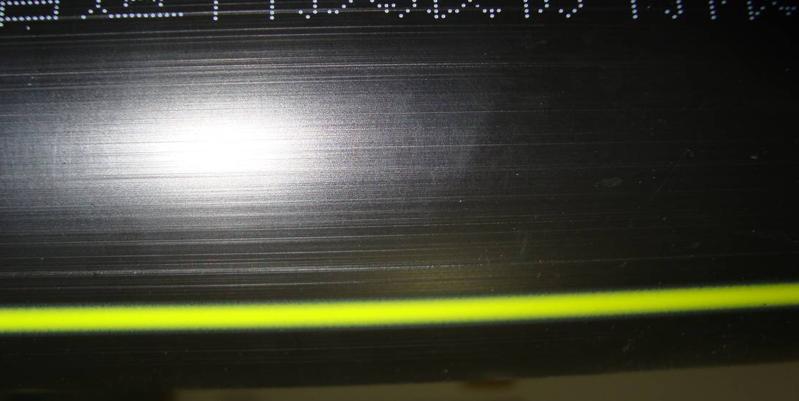

Surface Scratches on PE Pipes

Reason | Solution |

Debris or roughness in sizing sleeve | Clean sizing sleeve |

Unpolished calibration blocks | Clean calibration blocks (polish before startup) |

Misaligned cutter center | Adjust cutter center position |

Preventive Measures:

Keep vacuum tank and sizing sleeve clean (especially sawdust).

Clean sizing sleeve and blocks before startup.

Prevent sawdust from entering the sizing sleeve during cutting.

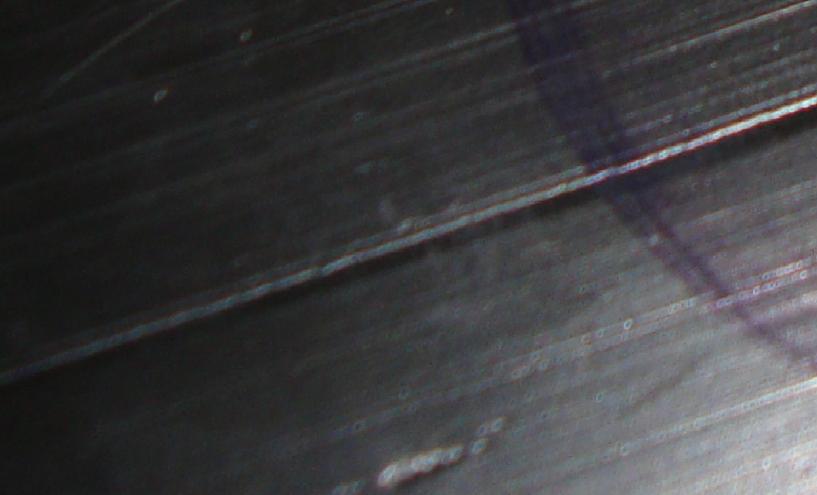

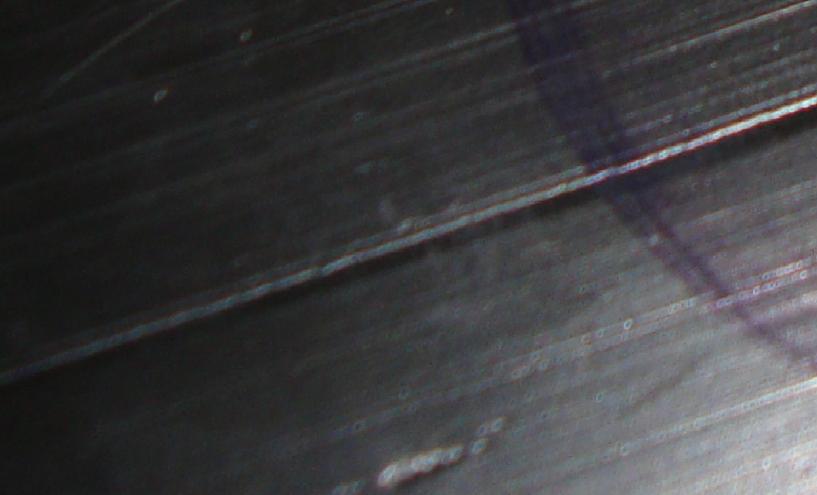

Raised/Sunken Lines on PE Pipes

Reason | Solution |

(1) Debris in die/calibrator

(2) Low temperature causing visible flow lines

(3) Excessive PPA (fluoropolymer additive) | (1) Clean die/calibrator

(2) Increase die body temperature

(3) Reduce PPA dosage |

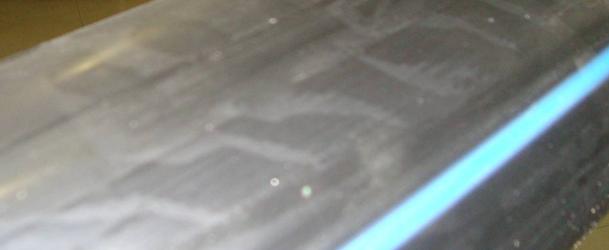

Patterned Outer Wall of PE pipe

Reason | Solution |

(1) Barrel/die temperature too high

(2) Calibrator too close to die

(3) Excessive water flow in sizing sleeve | (1) Adjust process temperature

(2) Adjust die and calibrator distance

(3) Reduce water flow |

Slanted Cuts

Reason | Solution |

(1) Cutter speed ≠ production speed

(2) Loose cutter arm | (1) Synchronize cutter and pipe speeds

(2) Repair by technician |

Uneven Wall Thickness

Reason | Solution |

(1) Unadjusted wall thickness

(2) Haul-off speed ≠ extruder output

(3) Uneven water flow in sizing sleeve

(4) Haul-off slippage | (1) Adjust wall thickness screws

(2) Tune haul-off speed

(3) Balance water flow

(4) Adjust haul-off air pressure |

Pitting on Pipe Surface

Reason | Solution |

(1) Pitting on inner/outer walls

(2) Outer pitting (low die temperature)

(3) Inner pitting (low barrel temperature)

(4) Localized outer pitting | (1) Replace material per procedure

(2) Increase die temperature

(3) Raise barrel temperature

(4) Add PPA as specified |

Preventive Measures:

Increase process temperature during startup.

Follow material replacement procedures.

Start production with high-quality material.

Dents on Outer Surface

Reason | Solution |

(1) Over-tightened water ring

(2) Debris in sizing sleeve

(3) Excessive inlet water pressure | (1) Loosen water ring

(2) Clean sizing sleeve

(3) Reduce inlet pressure |

Preventive Measures:

Regular tactile inspection and visual checks.

Inconsistent Color Stripe Thickness

Reason | Solution |

Partially clogged ring | Clean color ring |

Preventive Measures:

Keep colorant clean; cover hopper.

Oversized/Undersized Outer Diameter

Reason | Solution |

(1) Vacuum too high/low

(2) Excessive speed/water temperature

(3) Incorrect sizing sleeve | (1) Adjust vacuum

(2) Reduce speed/water temperature

(3) Replace sizing sleeve |

Preventive Measures:

Document vacuum/speed impact data.

Enhance measurement frequency.

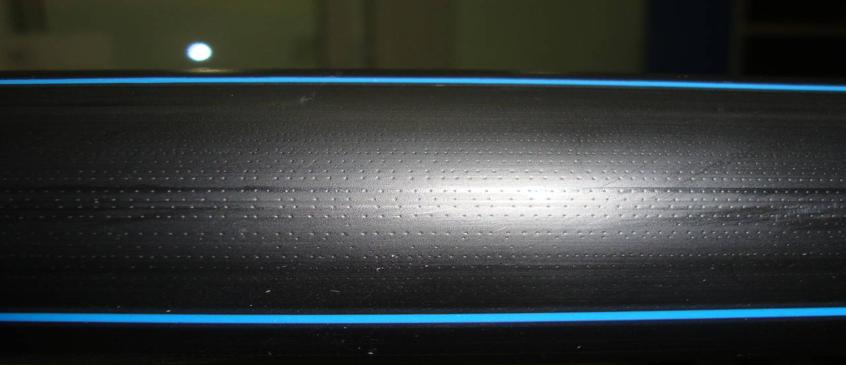

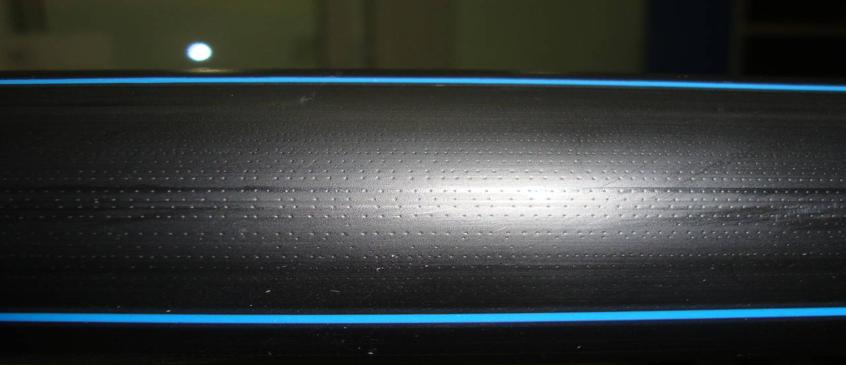

Circular Spots

Reason | Solution |

(1) Excess air in calibration tank water

(2) High inlet water pressure

(3) Excessive air intake in sizing sleeve

(4) Low water pressure

(5) Excessive intermediate cooling

(6) Damaged sizing sleeve | (1) Check pump room

(2) Reduce water flow near spots

(3) Adjust calibration tank position

(4) Clean nozzles

(5) Inspect water pump

(6) Replace sizing sleeve |

Preventive Measures:

Bleed air from pumps; inspect pipes visually/tactually.

Check water tank for debris before/after startup.

Dull Surface

Reason | Solution |

(1) Low die temperature

(2) Low barrel temperature

(3) Moist material

(4) Die/sleeve mismatch | (1) Raise die temperature

(2) Increase barrel temperature

(3) Replace material

(4) Replace sizing sleeve |

Setup Tip:

Set process temperature based on material properties before startup.

Glossy Outer Wall

Reason | Solution |

(1) Excessive vacuum

(2) No water in sizing sleeve | (1) Increase temperature

(2) Replace die/sizing sleeve |

Preventive Measures:

Monitor closely during startup or water pressure changes.

Inconsistent Pipe Lengths

Reason | Solution |

(1) Misaligned cutter/stop position

(2) Incorrect length counter placement | (1) Adjust cutter at startup

(2) Reposition counter |

Preventive Measures:

Strengthen checks during startup/production.

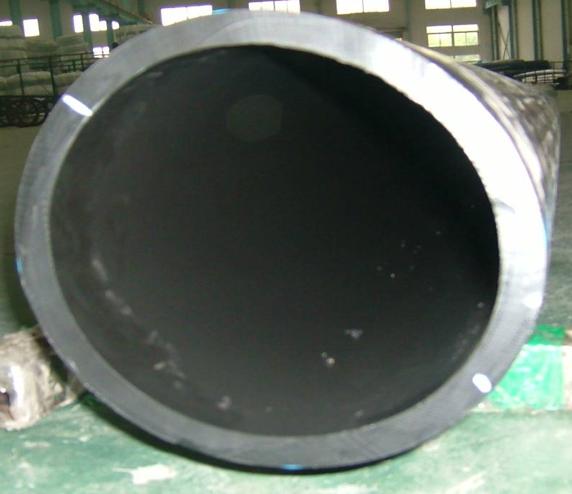

Bubbles on Inner Wall

Reason | Solution |

Insufficient material drying | Extend drying time or raise drying temperature. |

Preventive Measures:

Strictly follow drying protocols.

(16) Water Ripple Patterns

Reason | Solution |

(1) Inadequate cooling

(2) Undersized sizing sleeve seal

(3) High process temperature

(4) Misaligned cooling tank blocks

(5) Sizing sleeve too close to die

(6) Equipment malfunction | (1) Adjust cooling water flow

(2) Optimize process temperature

(3) Adjust production speed Preventive Measures: Set appropriate temperatures for materials. Ensure sizing sleeve seals are sufficiently large. |

(17) Material Breakage

Reason | Solution |

(1) Dirty suction fan

(2) Equipment failure

(3) Blocked feed inlet | (1) Clean fan every 2 days/size change

(2) Remove blockages with wire |

Preventive Measures:

Clean if alarm light activates.

Inspect feed inlet frequently.

(18) Pipe Bulging

Reason | Solution |

(1) High vacuum during thin-wall startup

(2) Low water level for ≤DN63 sleeves

(3) Insufficient sleeve water flow

(4) Water cutoff/blocked front holes

(5) Small sleeve + high vacuum = high resistance

(6) Haul-off slippage

(7) Poor mold design

(8) Clogged nozzles/filters | (1) Optimize vacuum

(2) Adjust water level

(3) Increase water flow

(4) Clean sleeve regularly

(5) Replace sleeve/adjust vacuum

(6) Tune haul-off speed

(7) Modify/replace die/mandrel

(8) Clean nozzles/filters periodically |

Jiangsu Xinrongplas Machinery Co., Ltd. specializes in manufacturing various plastic pipe extrusion machines, such as PVC-O, UPVC, HDPE, and others. We very much look forward to cooperating with you.