News

Site Editor

Site

/uploads/5cb96e23627a5.png

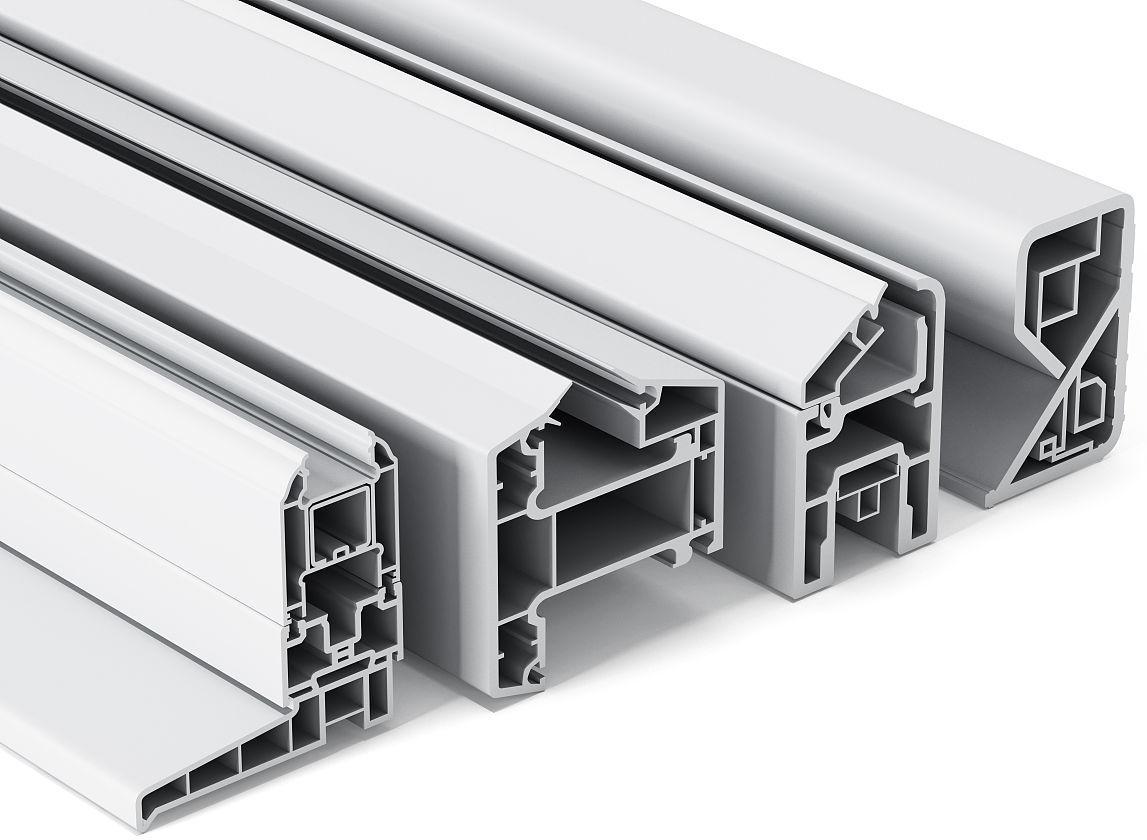

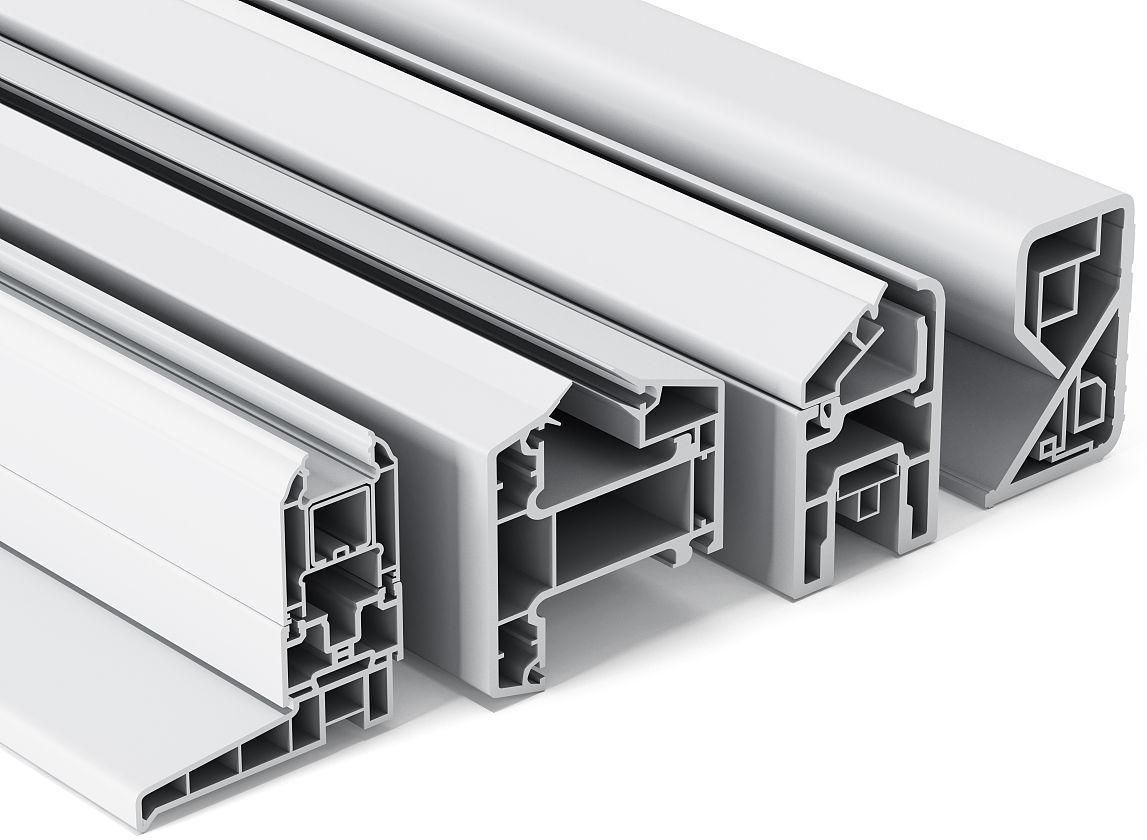

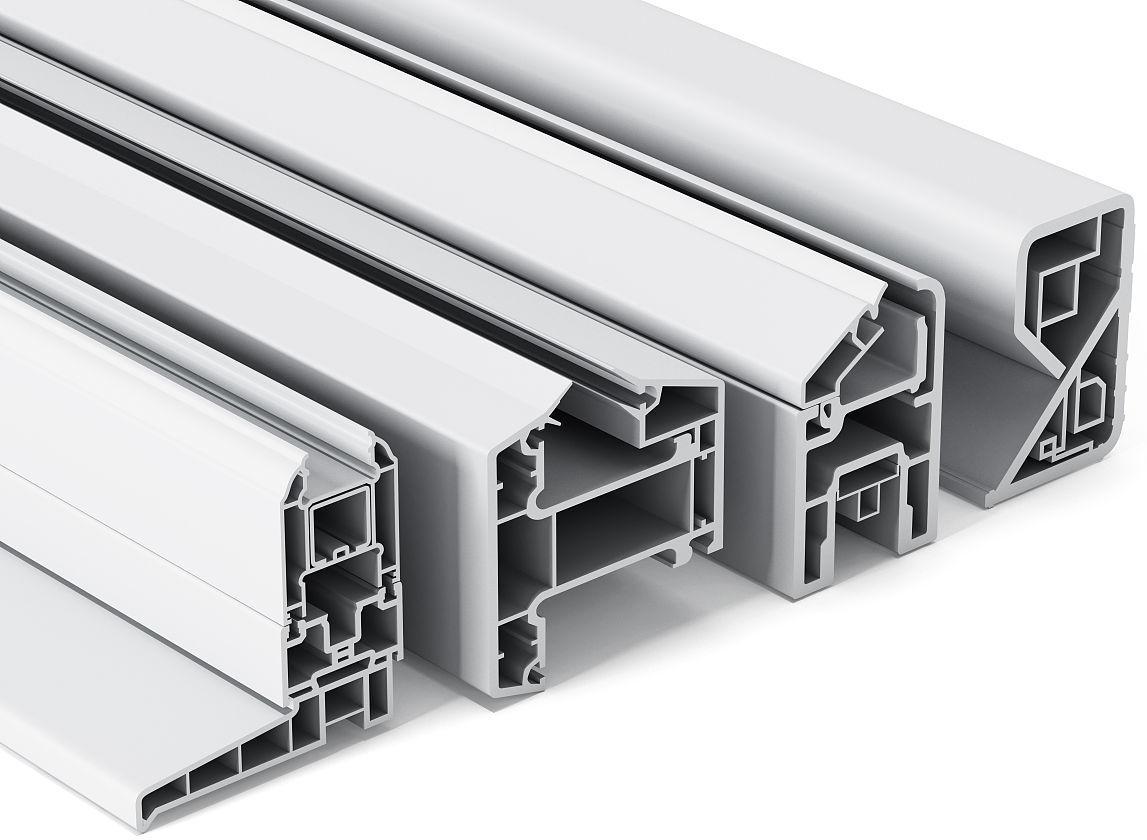

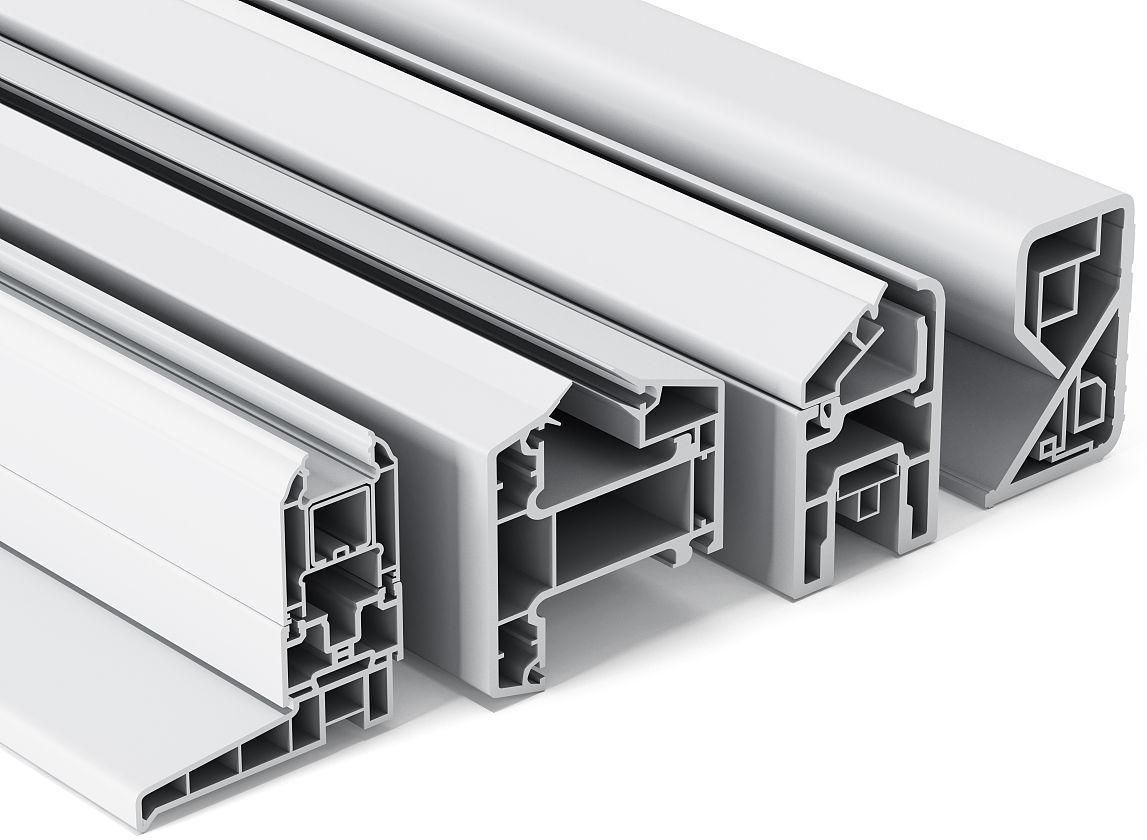

The factors that affect the low-temperature impact strength of PVC profiles include formula, profile cross-sectional structure, mold, plasticization degree, test conditions, etc.

Site

/uploads/5cb96e23627a5.png

The factors that affect the low-temperature impact strength of PVC profiles include formula, profile cross-sectional structure, mold, plasticization degree, test conditions, etc.

Low temperature impact strength of PVC profiles and solutions

Views: 370

Author: Site Editor

Publish Time: 2024-09-27

Origin: Site

Low-temperature impact strength

The factors that affect the low-temperature impact strength of PVC profiles include formula, profile cross-sectional structure, mold, plasticization degree, test conditions, etc.

(1) Formula

Currently, CPE is widely used as an impact modifier. Among them, CPE with a chlorine content of 36% has a better modification effect on PVC. The dosage is generally 8-12 parts by weight. The crystallinity and glass transition temperature are both low. It has good elasticity and compatibility with PVC.

(2) Profile cross-sectional structure

High-quality PVC profiles have good cross-sectional structure. Generally, the structure of a small cross-section is better than that of a large cross-section. The position of the internal ribs on the cross-section should be appropriately set. Increasing the thickness of the internal ribs and using arc transitions at the connection between the internal ribs and the wall can help improve the low-temperature impact strength.

(3) Mold

The influence of the mold on the low-temperature impact strength is mainly reflected in the melt pressure and stress control during cooling. Once the formula is determined, the melt pressure is mainly related to the die. The profiles coming out of the die will produce different stress distributions after different cooling methods. The low-temperature impact strength of the PVC profile is poor where the stress is concentrated. PVC profiles are prone to generate large stress when they are rapidly cooled, so the layout of the cooling water flow channel of the shaping mold is very critical. The water temperature is generally controlled at 14℃-16℃. The use of slow cooling is beneficial to improve the low-temperature impact strength of PVC profiles.

Ensure the good condition of the mold and clean the die regularly to avoid impurities blocking the die due to long-term continuous production, resulting in reduced discharge and too thin support ribs, which affects the low-temperature impact strength. Regular cleaning of the shaping mold can ensure sufficient shaping vacuum and water flow in the shaping mold to ensure that the profile is fully cooled during production, reduce defects, and reduce internal stress.

(4) Plasticization degree

A large number of research and test results show that the best value of the low-temperature impact strength of PVC profiles is obtained when the plasticization degree is 60%-70%. Experience shows that "high temperature and low speed" and "low temperature and high speed" can obtain the same plasticization degree. However, low temperature and high speed should be selected in production, because low temperature can reduce heating power consumption and high speed can improve production efficiency, and the shearing effect of the twin-screw extruder is very obvious during high-speed extrusion.

(5) Test conditions

GB/T8814-2004 has strict regulations on low-temperature impact tests, such as profile length, drop hammer mass, hammer head radius, sample freezing conditions, test environment, etc. In order to make the test results accurate, the above regulations must be strictly followed.

Among them, "drop hammer impact at the center of the sample" should be understood as "make the drop hammer impact at the center of the sample cavity", and such test results are more realistic.

The measures to improve low-temperature impact performance are as follows:

1. Strictly check the quality of materials, pay close attention to the material state of the die discharge and vacuum port. The die discharge should have consistent color, a certain glossiness, uniform discharge, and good elasticity when pinched by hand. The material at the vacuum port of the main machine is in a "tofu dregs" state, and cannot glow during initial plasticization. The parameters such as the main machine current and head pressure should be stable.

2. Standardize process control to ensure plasticization effect. The temperature control should be a "basin" process. The heating temperature change from the first zone of the extruder to the die head should be a "basin" type. The temperature of the third and fourth zones of the barrel is slightly lower, so that the material gradually changes from "hot outside and cold inside" to "balanced inside and outside" to ensure that the material is heated evenly. In the case of unchanged formula, the extrusion process should not have major changes.

Jiangsu Xinrongplas Machinery Co., Ltd. has been engaged in plastic extrusion recycling equipment for more than 28 years, if you are interested in our products, please contact us!