News

Site Editor

Site

/uploads/5cb96e23627a5.png

Recently, Jiangsu Xinrongplas Machinery Co., Ltd. successfully completed the test run of its PE 50-250 mm pipe production line and plans to ship it to Botswana, Africa. This milestone signifies the company's further expansion into the African market, showcasing its technological strength in the international plastic pipe production equipment industry.

Site

/uploads/5cb96e23627a5.png

Recently, Jiangsu Xinrongplas Machinery Co., Ltd. successfully completed the test run of its PE 50-250 mm pipe production line and plans to ship it to Botswana, Africa. This milestone signifies the company's further expansion into the African market, showcasing its technological strength in the international plastic pipe production equipment industry.

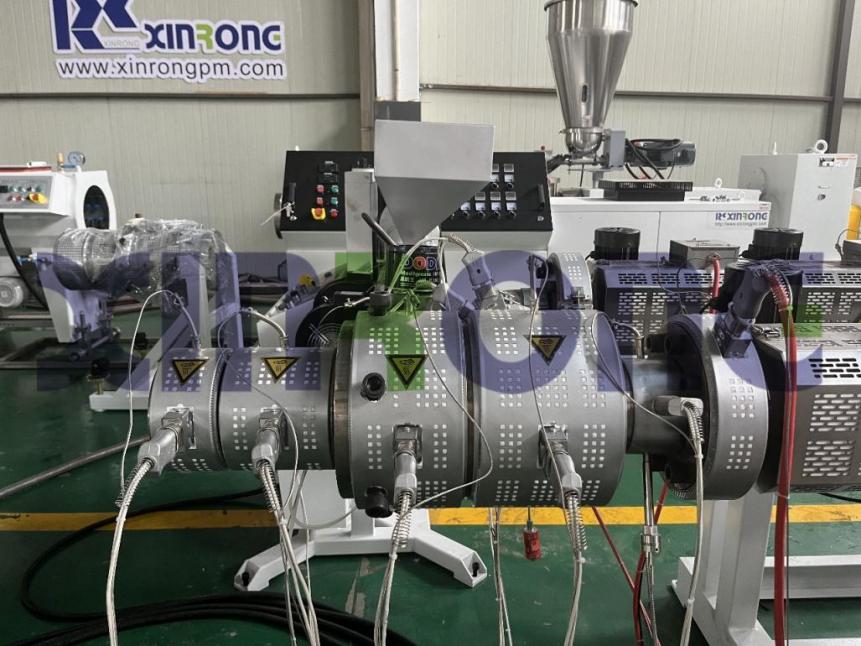

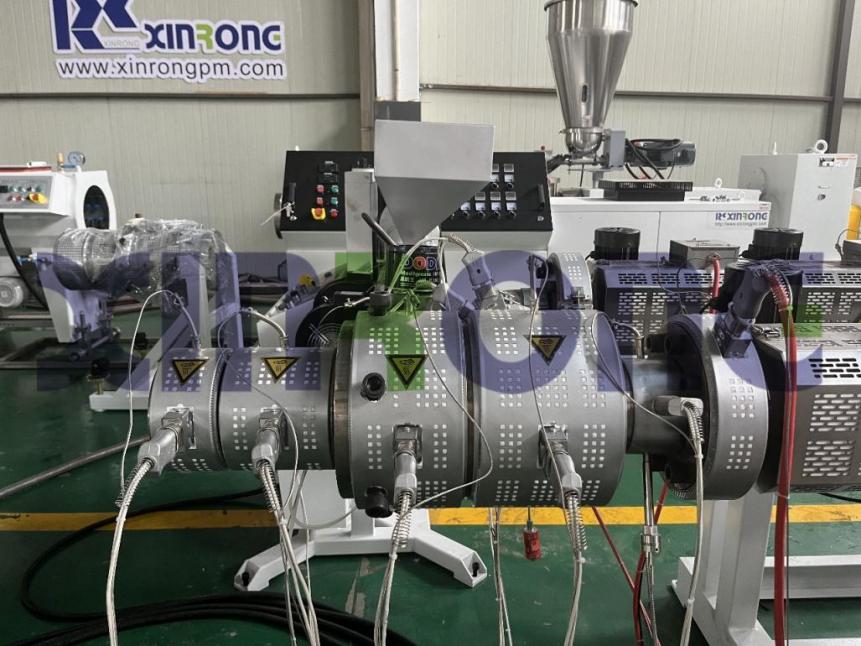

Successfully Test Run of PE 250 Pipe Production Line

Views: 405

Author: Site Editor

Publish Time: 2024-10-16

Origin: Site

Recently, Jiangsu Xinrongplas Machinery Co., Ltd. successfully completed the test run of its PE 50-250 mm pipe production line and plans to ship it to Botswana, Africa. This milestone signifies the company's further expansion into the African market, showcasing its technological strength in the international plastic pipe production equipment industry.

The PE 250 pipe production line consists of several key components, each working together to ensure efficient and stable pipe production:

1. Auto loader: This system transports raw materials, such as PE plastic granules, to the extruder via automated equipment, ensuring continuous and efficient production.

2. Single-Screw Extruder: The core equipment of the production line, this extruder melts the raw material at high temperatures and forms pipes through extrusion. Designed specifically for PE materials, it ensures stable plasticizing and high-efficiency extrusion.

3. Extrusion Mold: The mold determines the pipe's specifications and shape. The mold for the PE 250 line can be adjusted to produce pipes with a diameter of 250 mm. The mold features evenly distributed flow channels to ensure uniform pipe formation.

4. Vacuum Calibration Tank: After being extruded from the mold, the molten pipe is cooled and shaped in the vacuum calibration tank. Vacuum suction ensures the pipe has a smooth surface and precise dimensions.

5. Spray Cooling Tank: Following calibration, the pipe undergoes further cooling in the spray cooling tank, where evenly sprayed water further reduces the pipe's temperature and hardens it.

6. Haul-Off Machine: The haul-off machine pulls the cooled pipe from the water tank at a consistent speed, maintaining continuous extrusion and ensuring smooth operation of the production line. It uses a highly efficient clamping mechanism to prevent damage to the pipe surface.

7. Cutting Machine: At the final stage of production, the cutting machine precisely cuts the pipe to the pre-set length. The cutting process is smooth and vibration-free, ensuring clean, neat cuts.

8. Stacker: After cutting, the pipes are conveyed to the stacker, where they are neatly arranged for packaging and transportation.

During the test run, the production line performed stably, with the pipe products meeting international standards in terms of dimensional accuracy and thickness uniformity. The equipment also boasts energy-saving features, which reduce energy consumption and enhance production efficiency, providing customers with an efficient plastic pipe production solution.

As a leading domestic manufacturer of plastic pipe equipment, Jiangsu Xinrongplas Machinery Co., Ltd. continuously focuses on innovative technology to optimize the performance and efficiency of its production lines. The PE 50-250 mm pipe production line can produce pipes of various sizes and is widely applicable to water supply and drainage systems, agricultural irrigation, and urban infrastructure construction. With high automation, energy efficiency, and high production capacity, it is well-suited to meet the growing infrastructure needs of Botswana. This shipment will not only supply the local market with high-quality pipe production equipment but also help improve local water resource management and agricultural irrigation, contributing to regional economic growth.

Botswana, a key economy in southern Africa, has significantly increased its investment in infrastructure in recent years. This cooperation is not only a positive response to the market demand in Botswana but also part of Jiangsu Xinrong Puhler Machinery Co., Ltd.'s strategic plan to expand into the African market. As demand for high-quality pipe production equipment continues to grow in the region, the company will continue to provide innovative and sustainable production solutions to local customers.

This partnership is expected to further enhance our brand influence in the African region and drive the continuous expansion of our global business. Jiangsu Xinrongplas Machinery Co., Ltd. will continue to provide high-quality, innovative pipe production solutions and plastic recycling solutions. We welcome all inquiries and collaborations.