News

Site Editor

Site

/uploads/5cb96e23627a5.png

Aluminum-plastic pipes are a new type of composite pipe made up of a five-layer structure that combines the excellent properties of plastic and aluminum. Their unique structure allows aluminum-plastic pipes to excel in high-temperature resistance, pressure resistance, and corrosion resistance, making them widely used in building water supply, hot and cold water supply, and other fields.

Site

/uploads/5cb96e23627a5.png

Aluminum-plastic pipes are a new type of composite pipe made up of a five-layer structure that combines the excellent properties of plastic and aluminum. Their unique structure allows aluminum-plastic pipes to excel in high-temperature resistance, pressure resistance, and corrosion resistance, making them widely used in building water supply, hot and cold water supply, and other fields.

Production Process of PEX and PPR Composite Aluminum-Plastic Pipe Extrusion Line

Views: 505

Author: Site Editor

Publish Time: 2025-01-23

Origin: Site

Aluminum-plastic pipes are a new type of composite pipe made up of a five-layer structure that combines the excellent properties of plastic and aluminum. Their unique structure allows aluminum-plastic pipes to excel in high-temperature resistance, pressure resistance, and corrosion resistance, making them widely used in building water supply, hot and cold water supply, and other fields.

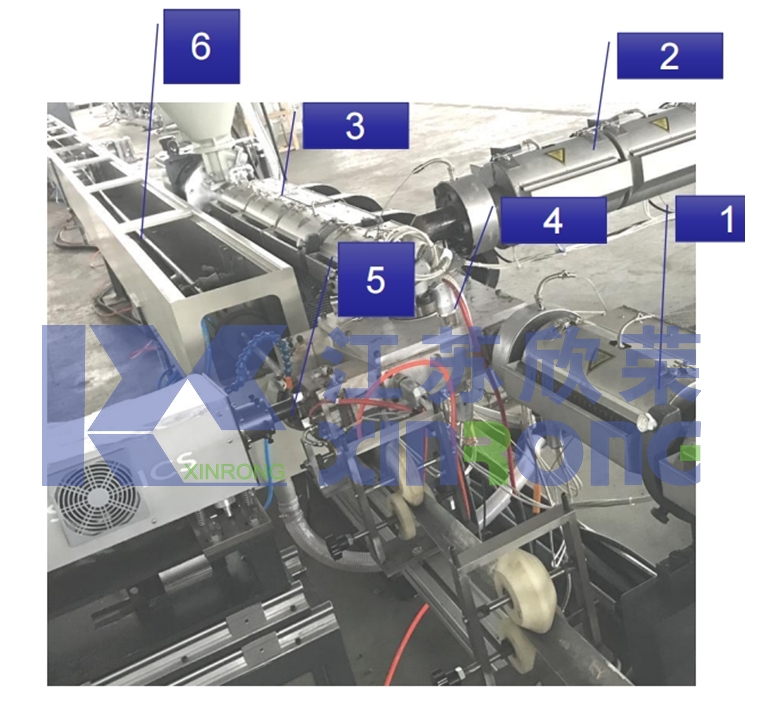

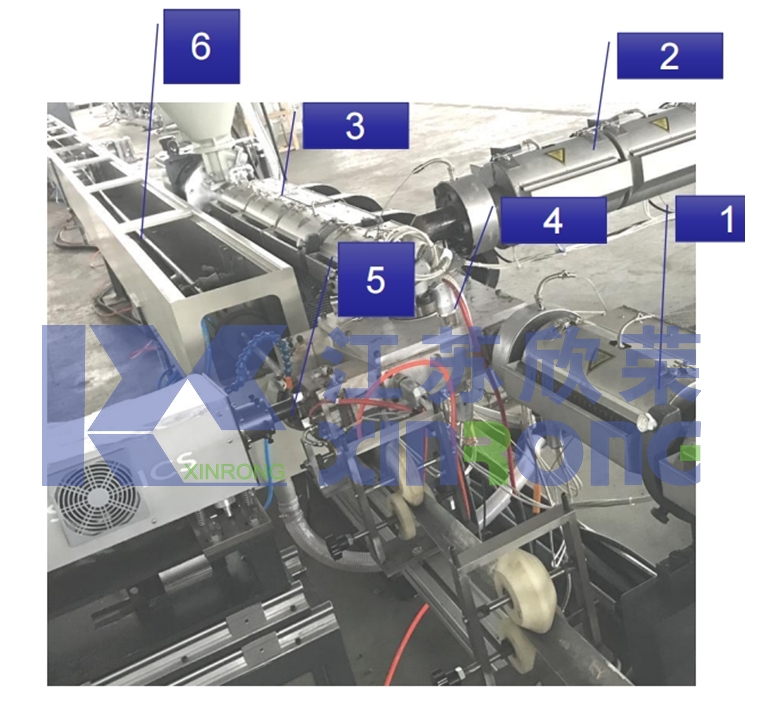

Overview of the Production Process

The production line for aluminum-plastic pipes mainly includes the following steps:

Raw Material Preparation

High-quality plastic materials and aluminum foil are used as the main raw materials.

Aluminum Foil Forming

The aluminum foil undergoes a special forming process to be transformed into aluminum pipes. This process ensures that the inner and outer walls of the aluminum pipe are smooth, improving welding quality and stability.

Ultrasonic Welding

During the co-extrusion production process, the aluminum pipe is connected to the PPR pipe using ultrasonic welding technology. This welding method is efficient and provides good welding results, allowing for stable welding in a short time and avoiding issues related to the heat-affected zone in traditional welding.

Five-Layer Co-Extrusion

The five-layer structure of PPR aluminum-plastic pipes includes:

1. Inner layer of plastic

2. Adhesive layer between the inner plastic layer and aluminum layer

3. Aluminum layer

4. Adhesive layer between the aluminum layer and outer plastic layer

5. Outer layer of plastic

Five-Layer Co-Extrusion

The five-layer structure of PPR aluminum-plastic pipes includes:

1. Inner layer of plastic

2. Adhesive layer between the inner plastic layer and aluminum layer

3. Aluminum layer

4. Adhesive layer between the aluminum layer and outer plastic layer

5. Outer layer of plastic

Advantages of Aluminum-Plastic Pipes

Compared to traditional plastic pipes, PEX and PPR aluminum-plastic pipes have the following significant advantages:

l Low Linear Expansion Coefficient: The linear expansion coefficient of aluminum-plastic pipes is low, allowing them to maintain shape stability during temperature changes, reducing deformation and damage to the pipes.

l Oxygen Barrier: The aluminum layer effectively isolates the penetration of oxygen, preventing oxidation reactions inside the pipe and extending the service life of the material.

l Strong Pressure Resistance: The addition of the aluminum layer gives the pipe superior pressure resistance, allowing it to adapt to higher working pressures and ensuring safe usage.

l High-Temperature Resistance: PPR aluminum-plastic pipes perform well under high-temperature conditions, suitable for hot water transport, and reduce the risk of deformation due to high temperatures.

Jiangsu Xinrongplas Machinery Co., Ltd. continuously optimizes the production process of aluminum-plastic pipes through innovative five-layer co-extrusion and ultrasonic welding technology, providing an efficient, environmentally friendly, and economical pipe solution. As the market demand for high-performance pipes continues to grow, PEX and PPR aluminum-plastic pipes are expected to play an increasingly important role in the piping industry. We look forward to providing customers with higher quality products and services.