News

Site Editor

Site

/uploads/5cb96e23627a5.png

PE pipes are widely used in daily life, and are reflected in water supply, chemical industry, commerce and other aspects. Although the pipes produced by PE pipe production lines are widely used, their characteristics are not well understood.

Site

/uploads/5cb96e23627a5.png

PE pipes are widely used in daily life, and are reflected in water supply, chemical industry, commerce and other aspects. Although the pipes produced by PE pipe production lines are widely used, their characteristics are not well understood.

Characteristics and common problems of PE pipe production line

Views: 553

Author: Site Editor

Publish Time: 2025-01-20

Origin: Site

PE pipes are widely used in daily life, and are reflected in water supply, chemical industry, commerce and other aspects. Although the pipes produced by PE pipe production lines are widely used, their characteristics are not well understood. Next, the PE pipe production line manufacturer will take you to understand:

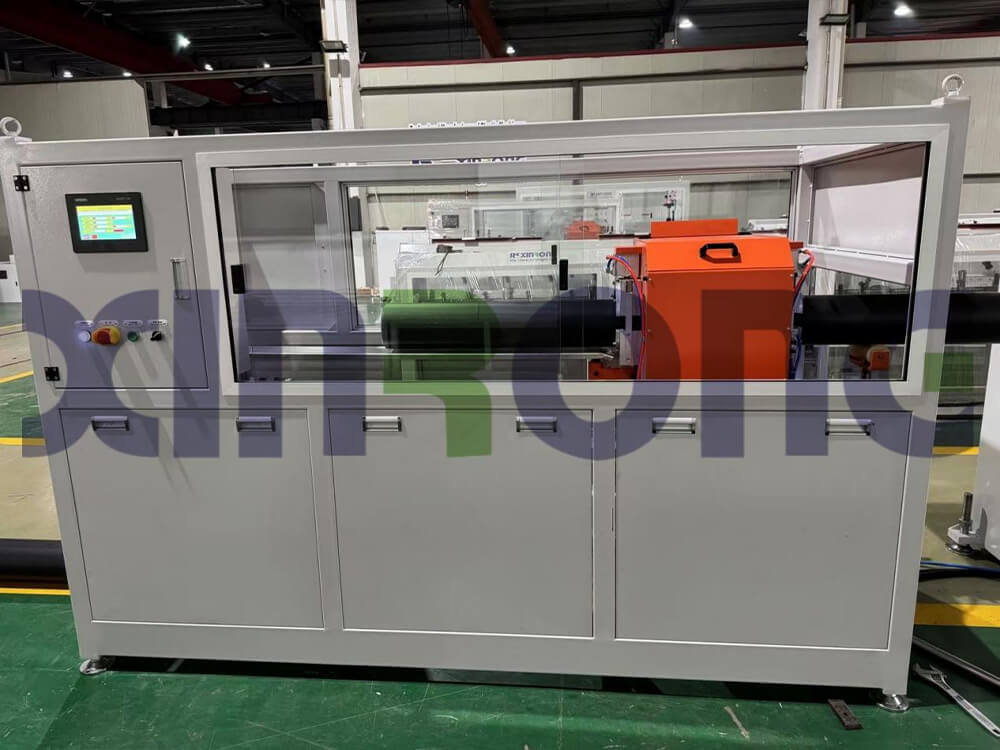

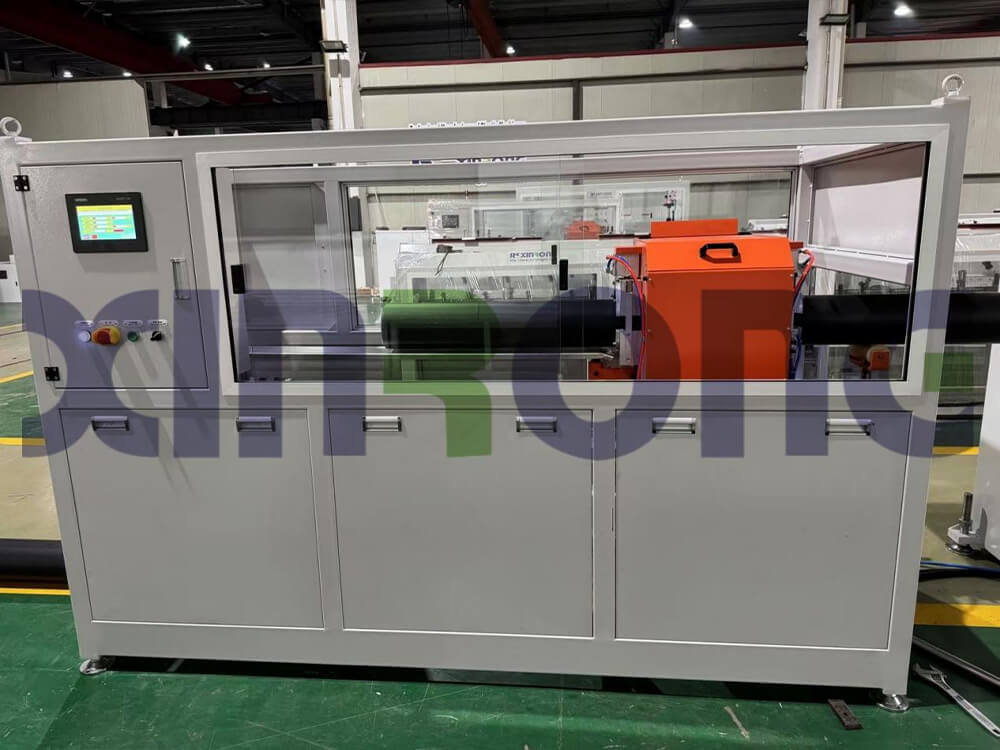

The PE pipe production line is a spiral die designed for HDPE and PP large-diameter thick-walled pipes. The die has the characteristics of low melt temperature, good mixing performance, low cavity pressure and stable production. The PE pipe high-speed production line adopts a proprietary sizing and cooling system, water film lubrication and water ring cooling to meet the requirements of HDPE and PP materials, ensuring the stability of diameter and roundness of high-speed production of thick-walled pipes.

The PE pipe high-speed production line uses a specially designed vacuum sizing box with multi-stage vacuum control to ensure the dimensional stability and roundness of HDPE and PP pipes. The extruder and haul-off are driven and controlled by imported speed regulators, which have good stability, high precision and high reliability.

Five major characteristics of PE pipes:

1. Reliable connection: The polyethylene pipe systems are connected by electric hot-melt, and the strength of the joints is higher than that of the pipe itself.

2. Good low-temperature impact resistance: The medium-strength low-temperature brittle temperature is extremely low and can be safely used in the temperature range of -60-60℃. During winter construction, the pipe will not crack due to the good impact resistance of the material.

3. Good resistance to stress cracking: HDPE has low notch sensitivity, high shear strength and excellent scratch resistance, and its resistance to environmental stress cracking is also very outstanding.

4. Good chemical corrosion resistance: HDPE pipes are resistant to corrosion from a variety of chemical media, and the chemicals present in the soil will not cause any degradation to the pipes. Polyethylene is an electrical insulator, so it will not rot, rust; in addition, it will not promote the growth of algae, bacteria or fungi.

5. Aging resistance and long service life: Polyethylene pipes containing 2-2.5% evenly distributed carbon black can be stored or used outdoors for 50 years without being damaged by ultraviolet radiation.

PE pipe production line manufacturers will show you the common problems in PE pipe production:

1. Pipe wall thickness control

The thickness of PE pipes involves the compression resistance of pipes, and the thickness control of pipes also involves the cost of products. The wall thickness index of pipes is an important parameter for pipe quality management. If the wall thickness is unqualified, it is a new project with strong product quality, so it is very important to control the wall thickness of pipes. The factors that lead to poor wall thickness of pipes are unstable server dispute quantity. On the one hand, the solution flow (MFR) of raw materials is unstable, and more importantly, the temperature of machines, equipment, servers and hosts during the production process. On the other hand, the PE material is dirty and the machine mold tower is not suitable.

2. Pipe diameter control

There are many factors that lead to the failure of the outer diameter of pipe fittings. If the outer diameter of the pipe fittings is not uniformly qualified, it will lead to the failure to ensure the welding quality of the pipe fittings during hot melt or electric fusion welding. Even due to the special fault of the joint, it cannot be welded. Therefore, the arrangement of the diameter of the pipe fittings is also very important. The business of the manufacturing enterprise should be completed carefully. On the one hand, it is necessary to ensure compliance with the standards and national industry standards, and on the other hand, it should be stable. Specific table 2. The round (diameter) operation in the production of pipe fittings has a lag effect. It takes several hours to completely freeze on the mold or diameter setting, which sometimes leads to continuous special excavation or waste.

3. Different centrality operation

During the production process of pipe fittings, it is easy to cause the pipe fittings to be out of round, which can easily cause welding difficulties. Therefore, the problem of different centrality of pipe fittings also needs to be paid attention to. On the one hand, there are too few semicircular pads for pipe fittings, which cannot meet the standards; on the other hand, the concentricity calibrator of pipe fittings is not calibrated in time or is calibrated too much. In addition, the main reason for the excessive different centrality of pipe fittings is still the wall thickness problem. If the wall thickness is uneven and round, it is also easy to cause the pipe fittings to be out of round. Finding a way to deal with the symmetry of the wall thickness of pipe fittings is to solve the basic problem of different centrality of pipe fittings; in addition, the cooling effect of pipe fittings is not very good because the nozzle is blocked during the production process. Perhaps the nozzle angle is not scientific, resulting in uneven cooling during the production of pipe fittings, which is also the main reason for the excessive different centrality of pipe fittings.

In addition, the natural environment in which the pipes are stored is poor, there is too much accumulation, the pipes are piled up outdoors, and the ground temperature is too high in summer. Under the action of ground stress, the ovality of the pipes will exceed the standard.

In addition to PE pipe extruder equipment, our company specializes in the production of various plastic pipe production lines. If necessary, you can consult related content at any time and look forward to our cooperation.