In modern construction and drainage systems, UPVC (Unplasticized Polyvinyl Chloride) pipes have become widely used due to their excellent physical and chemical properties. This article will detail the processing technology of UPVC pipes, including raw material preparation, composition and function of materials, mixing, extrusion production line, and product inspection.

1. Raw Material Preparation

The production of UPVC pipes begins with raw material preparation. The main raw material is polyvinyl chloride (PVC), and additional auxiliary materials such as stabilizers, lubricants, fillers, and color masterbatches are also required. These materials must be strictly selected to ensure their quality meets production standards.

1.1 Material of PVC pipe

Composition and Function of Materials

The main components of UPVC pipes and their functions are as follows:

l PVC Resin: Provides the basic structure and strength of the pipe, determining its durability.

l Stabilizers: Prevent the degradation of PVC during processing, ensuring product durability.

l Lubricants: Improve processing performance, reduce friction, and ensure uniform material flow.

l Fillers: Lower production costs while enhancing the physical properties of the pipes.

l Color Masterbatches: Enhance the visual effect of the pipes and serve as usage identifiers.

2. Mixing

During the mixing phase, all materials are accurately weighed according to the predetermined formula and thoroughly mixed in mixing equipment. This process ensures that all components are evenly distributed and optimizes the performance of the final product through the addition of pre-mixed additives.

Customers can use either a separate mixing machine or a fully automatic/semi-automatic PVC mixing system based on actual conditions.

Fully Automatic/Semi-Automatic PVC Raw Material Mixing System Includes:

Material Collection System: The designed bag-opening station operates both automatically and manually or can feed through bulk bags, ensuring smooth material flow. A dust collection system is set at the entrance to effectively prevent dust generation.

Material Conveying System: The material conveying system uses efficient pneumatic and spiral conveying methods, with a simple structure and reliable operation, capable of long-distance transport.

Weighing and Dosing Unit: The dosing system consists of two independent weighing units for main and auxiliary materials, designed rationally to improve dosing accuracy and ensure high efficiency during production.

Mixing Equipment: The high-cool mixing unit is a crucial component of our system, combining high-speed hot mixing and cold mixing to ensure optimal mixing results.

Material Storage Equipment: Made of high-quality stainless steel and featuring an efficient automatic control system, it ensures safe storage of materials and smooth material entry and exit.

Dust Removal System: Depending on the usage scenario, our dust collectors use advanced filtration materials to ensure a clean production environment. The dust removal system is designed reasonably to effectively collect and filter dust generated during production, maintaining a good working environment.

Electrical System: The electrical control system links the entire set of equipment, ensuring the stable operation of the mixing line over the long term, with automatic detection and alarm functions to enhance production safety.

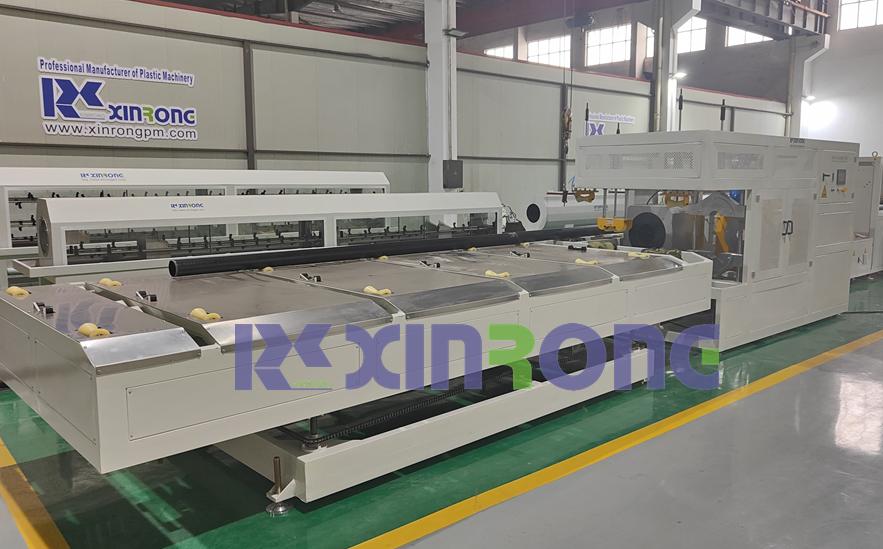

3. PVC Pipe Extrusion Production Line

After mixing is complete, the material enters the extrusion production line. In the extruder, the mixed material is melted at high temperatures and extruded through specially shaped molds to form pipes. During this process, it is essential to strictly control the temperature, pressure, and speed of the extruder to ensure the quality of the pipe formation.

3.1 Extrusion Process Control

Temperature Control: The extruder's temperature is generally set between 160-220 degrees Celsius to ensure smooth melting of PVC.

Pressure Adjustment: The screw speed and heating zone temperature are adjusted to maintain appropriate pressure during the extrusion process.

Speed Control: The extrusion speed is set reasonably to ensure consistency and stability of the pipe.

3.2 Vacuum calibration and Cooling

The extruded pipes are rapidly cooled through a vacuum calibration and cooling system to ensure they form a stable structure. The cooling method typically involves water baths to guarantee a smooth and defect-free surface.

3.3 Haul off traction.

After pipe extrusion, the traction process is essential for ensuring uniform shaping and stability of the pipes. The traction system controls the stretching speed of the pipes to ensure their outer diameter and wall thickness are consistent.

Haul off Machine: Each belt or caterpillar is controlled by an independent motor. The design considers sufficient traction force, ensuring that even if one motor fails, the remaining tracks have enough traction to continue the process.

Traction Speed: The traction speed is synchronized with the speed of the extruder and controlled by a PLC to avoid deformation or slipping of the pipes due to excessive or insufficient speed.

3.4 Cutting

The cooled pipes are cut to the required length, using either dust-free cutting or planetary cutting methods, with suitable tools and cutting machine types selected based on actual conditions.

Pipe Inspection:

Inspection items include appearance, dimensions, wall thickness, and pressure resistance to ensure compliance with industry standards.

4. Belling of PVC Pipes (PVC Socket Machine)

The Belling machine is a crucial step in the production of UPVC pipes, primarily aimed at enhancing the sealing and reliability of pipe connections. The main principle involves heating the ends of the pipes to soften them and then using expansion molds to expand the pipes to the required diameter.

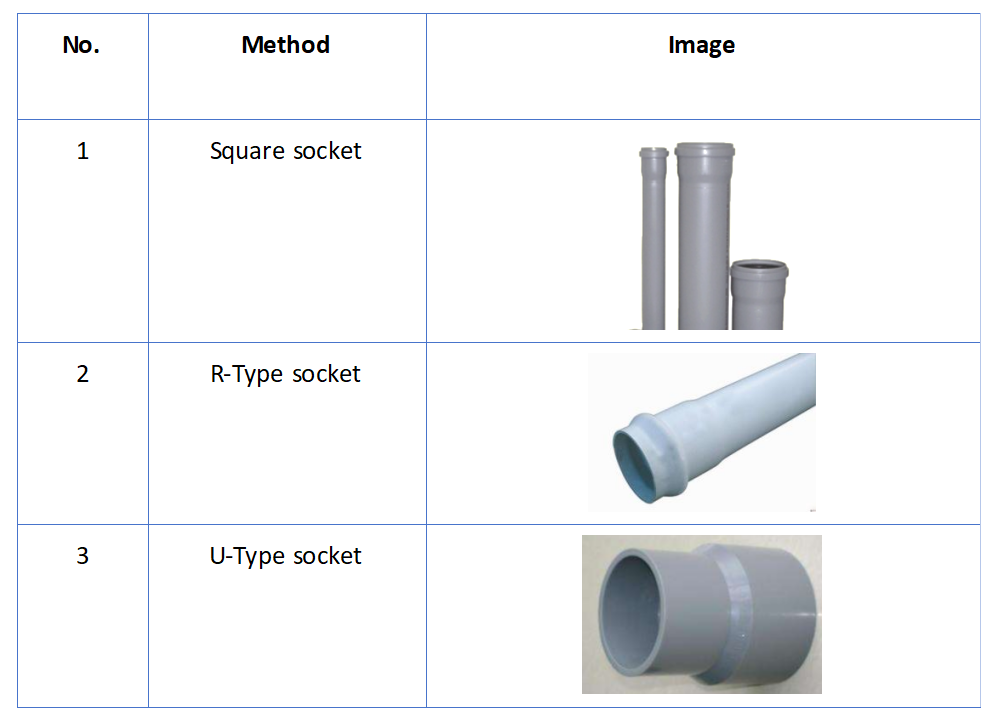

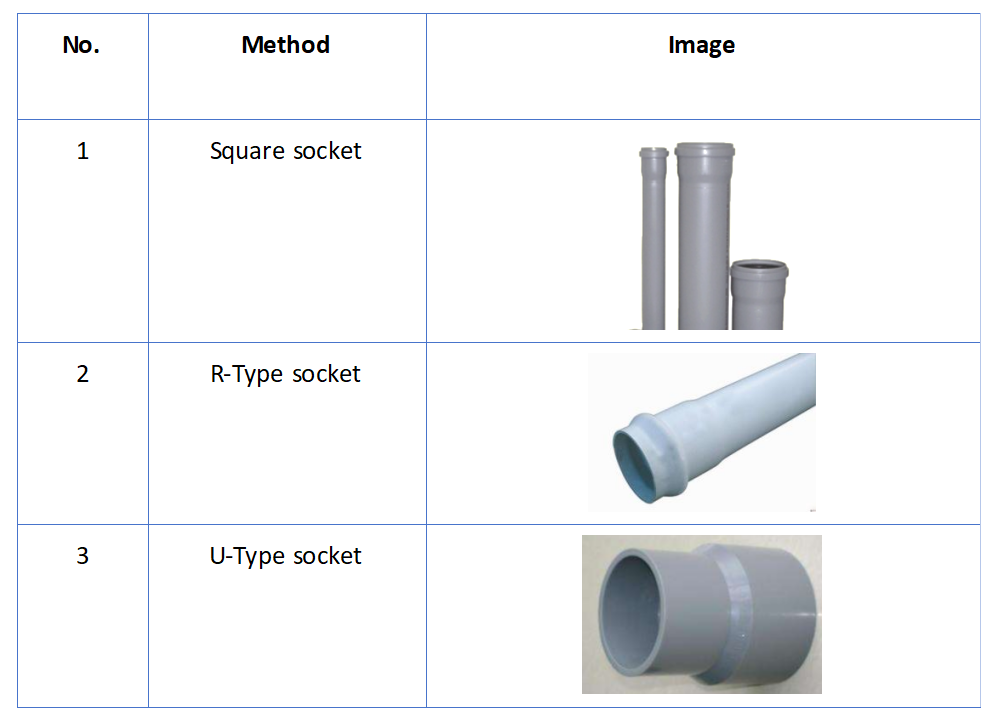

Common expansion methods for PVC pipes are as follows:

5. Product Inspection and Quality Control

Throughout the production process, product inspection and quality control are vital. Each batch of produced pipes undergoes rigorous physical and chemical performance testing to ensure compliance with national and industry standards. Inspection items include:

Pressure Resistance Testing: Ensures the pipes are safe under high-pressure conditions.

Corrosion Resistance Testing: Evaluates the performance of pipes in various chemical environments.

Dimensional Accuracy Testing: Ensures the outer diameter and wall thickness of the pipes meet design requirements.

The processing technology of UPVC pipes encompasses multiple stages from raw material preparation to finished product inspection. Through advanced processes and strict quality control, UPVC pipes exhibit excellent corrosion resistance, pressure resistance, and longevity, making them indispensable materials in modern water supply systems. With continuous technological advancements, the application prospects for UPVC pipes will broaden, providing more reliable solutions for construction and hydraulic engineering.

Jiangsu Xinrongplas Machinery Co., Ltd., with 30 years of experience in plastic pipe equipment production, provides professional solutions for plastic pipe production lines and is equipped with a dedicated after-sales service team to offer customers fast and high-quality service.