News

Site Editor

Site

/uploads/5cb96e23627a5.png

The shaping device in the mold is the main component of the PE pipe extrusion line. The molten material is cooled down on the inner surface of the caliberator to form a solid surface layer to ensure that the pipe obtains an accurate outer diameter. It also ensures the stability of the pipe and the normal traction and extrusion. The state and molding conditions of the molten material in the shaping device directly affect the internal and external surface quality of the pipe, and also directly determine the stability of the entire extrusion line and the reliability of high-speed production.

Site

/uploads/5cb96e23627a5.png

The shaping device in the mold is the main component of the PE pipe extrusion line. The molten material is cooled down on the inner surface of the caliberator to form a solid surface layer to ensure that the pipe obtains an accurate outer diameter. It also ensures the stability of the pipe and the normal traction and extrusion. The state and molding conditions of the molten material in the shaping device directly affect the internal and external surface quality of the pipe, and also directly determine the stability of the entire extrusion line and the reliability of high-speed production.

What are the basic requirements for the shaping device of the PE pipe extrusion line?

Views: 960

Author: Site Editor

Publish Time: 2021-05-22

Origin: Site

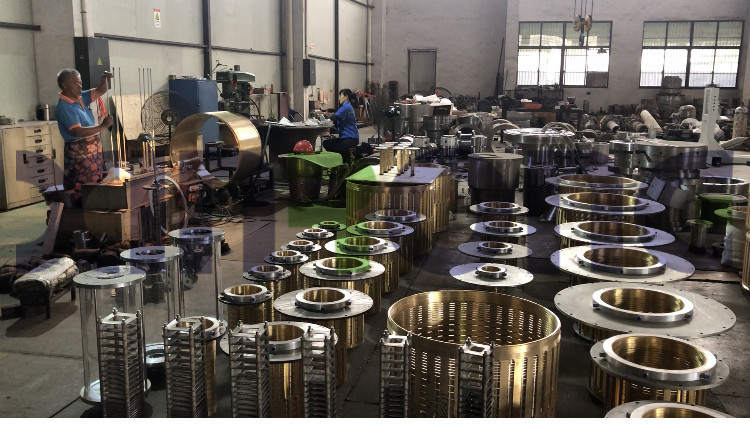

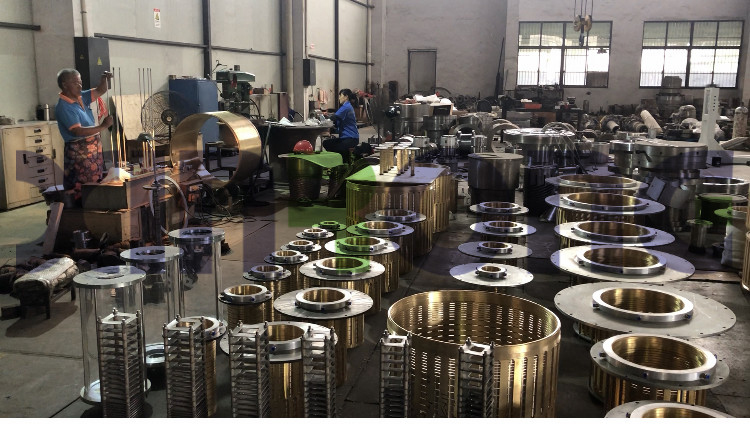

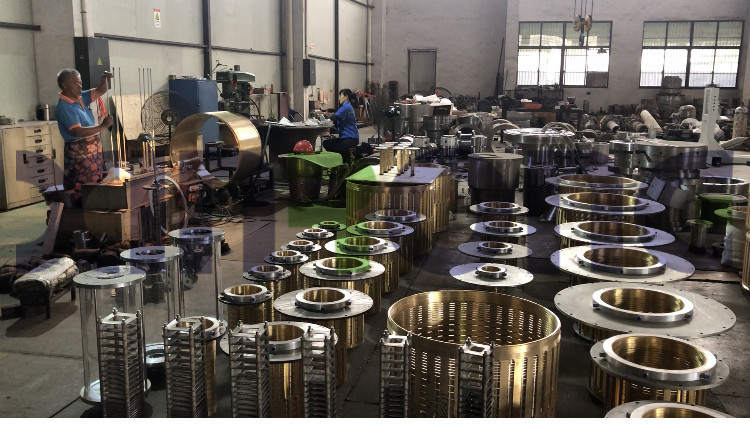

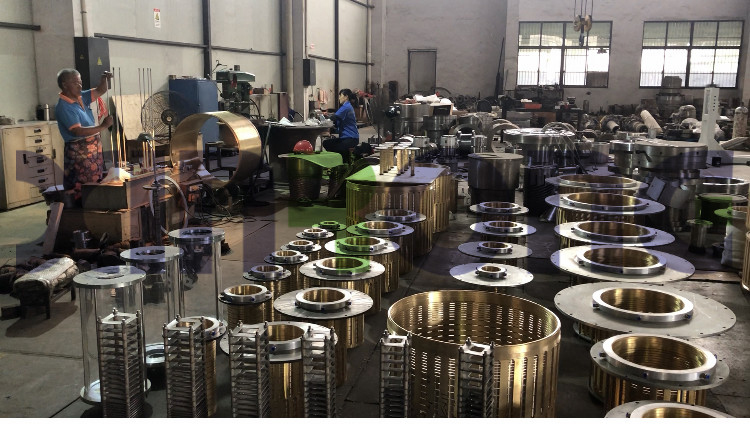

The shaping device in the mold is the main component of the PE pipe extrusion line. The molten material is cooled down on the inner surface of the caliberator to form a solid surface layer to ensure that the pipe obtains an accurate outer diameter. It also ensures the stability of the pipe and the normal traction and extrusion. The state and molding conditions of the molten material in the shaping device directly affect the internal and external surface quality of the pipe, and also directly determine the stability of the entire extrusion line and the reliability of high-speed production.

Therefore, a good shaping device design should meet the following three requirements:

①Good thermal conductivity provides rapid and sufficient surface cooling of the molten material in a short distance, and the cooling rate can ensure that the surface of the pipe quickly forms a solid phase skin layer.

②High wear resistance.

③The inner surface should have a high degree of smoothness.

According to different materials, production speed and quality requirements, different shaping structures can be selected. At present, there are mainly two popular PE pipe shaping devices: cylindrical sizing sleeves and sheet-shaped combined calibrator.

Among these two sizing devices, cylindrical sizing sleeves are widely used. It has a wide range of applicable properties and can meet the extrusion molding of PE pipes from Φ20 to Φ630:

①For the cylindrical sizing sleeve, the stability and uniformity of the water flow introduced into the water ring directly affects the extrusion quality of the pipe, and the cooling rate of the molten material in the calibrator can directly affect the quality of the inner wall of the pipe.

②The sheet-shaped combined sizing sleeve is mainly for the production of small-diameter, high-speed extruded PE pipes. The applicable caliber range: Φ20~Φ63MM. Depending on the diameter of the pipe and the material being processed, it can reach 35M/MIN or higher extrusion speed. The sheet-shaped shaping device is composed of multiple thin copper sheets, with a sizing round hole in the middle, and the outside is fixed by a support column. The distance between each layer of thin copper sheets is distributed according to the following rules: along the direction of billet introduction. The distance gradually increases. The smaller the distance between the copper sheets near the inlet end of the billet is to prevent the plasticized billet from accumulating and squeezing between the sheets. With the formation of a hard layer on the surface of the pipe, the distance between the copper sheets The distance can be gradually increased.

Therefore, a reasonable choice of tube shaping device plays a decisive role in the production quality and economic benefits of the tube!

Jiangsu Xinrongplas Machinery Co.,Ltd is professional in manufacturing various plastic pipe extrusion lines such as PPR Pipe extrusion line, PE pipe extrusion line, PVC pipe extrusion line, welcome to consult!