News

Xinrongplas

Site

/uploads/5cb96e23627a5.png

In our houses, the sewerage system is controlled by pipes. These pipes are essential when we discuss our health safety. I am sure all of us know about the importance of these pipes that lay the sewerage system. However; many of us don' t understand how these pipes are produced.

Site

/uploads/5cb96e23627a5.png

In our houses, the sewerage system is controlled by pipes. These pipes are essential when we discuss our health safety. I am sure all of us know about the importance of these pipes that lay the sewerage system. However; many of us don' t understand how these pipes are produced.

You Know How Pipes That Lay Sewers are Produced?

Views: 1195

Author: Xinrongplas

Publish Time: 2019-07-16

Origin: Site

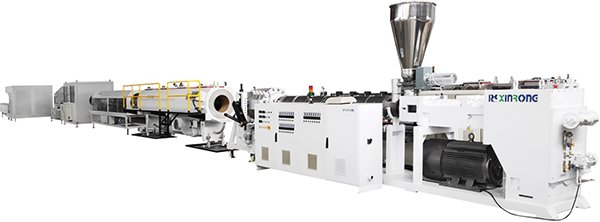

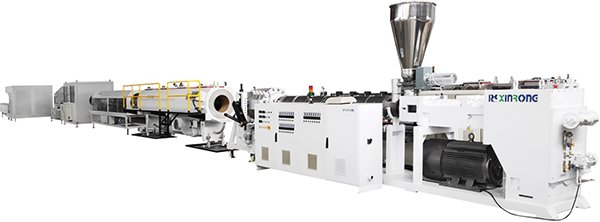

In our houses, the sewerage system is controlled by pipes. These pipes are essential when we discuss our health safety. I am sure all of us know about the importance of these pipes that lay the sewerage system. However; many of us don' t understand how these pipes are produced. There are different companies and industries around the world which manufacture these pipes. A China-based company named XINRONGPLAS is manufacturing and dealing in plastic machinery for many years, and they are also producing PVC pipe making machine and other similar machines.

PE pipe extrusion line is a type of machine made by the company for the production of sewerage pipes. This extrusion machine can be used to process different type of materials like PP, PPH, PPB, HDPE, LDPE, etc. The extrusion line can produce both single layer and multi-layered pipes of various sizes. The range of size produced by the company is from 16mm to 2000mm.

Further; the extrusion line also can produce 1000kg of pipes within an hour. For the removal of the confluence eam, the extrusion line has a spiral structure which helps in maintaining the quality of the product. For ensuring the quality of the pipe, a vacuum tank is included in the line as well.

The company also makes PVC pipe production line. The PVC line is available in different types and You can avail four cavity line, double cavity line, and a large diameter line. For better customization and customer care, the company can also provide you with the formula of the PVC production line so you can adjust your manufacturing and production procedure as per the provided formula.

This PVC production line can produce both multi-layered and single layered pipes of different range. The pipe production range varies from 16mm to 1000mm. For ensuring the plastic effects and high capacity, the machine has twin screw extruder included in the production line.

The pipe made by PVC pipe making machine generally has high temperature and also has a little bit of different shape. So, in the production line, the vacuum tank is included. This vacuum tank is used for decreasing the temperature of the produced pipes and also are used for shaping the pipes in proper structure. The vacuum tank has a double chamber structure. The first chamber is used for vacuum and cooling function. Further; the second chamber is used the quick and better formation of the pipe structure.

Just like other high-quality machines in the market, PVC production line also has customization feature for the customers. The machine has a PLC control system with the help of which you can use control the production quality, working procedure, and the pipe size.

The PLC controls system is also linked with the cutter of the machine. This connection between cutter and PLC system allows you to adjust the size of the pipes as per your requirement.

In case the required temperature of the pipe is not achieved by the vacuum tank, a separate cooling tank can also be used.