2020-11-04

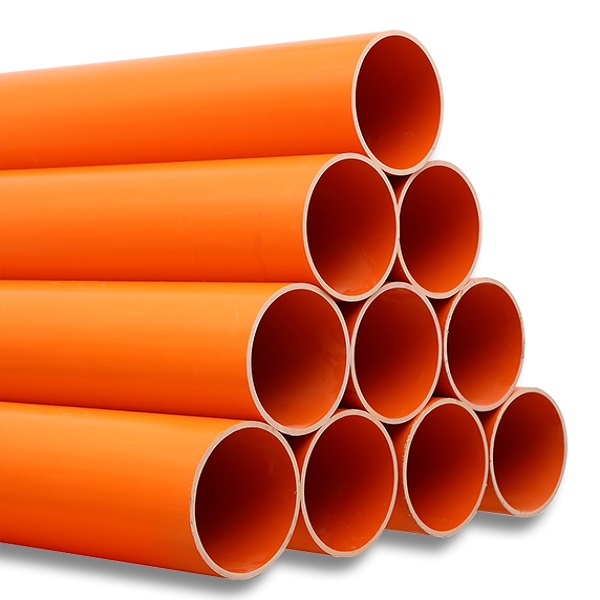

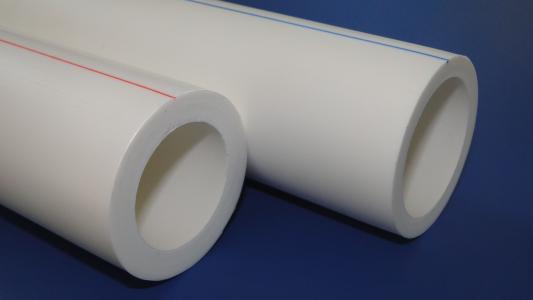

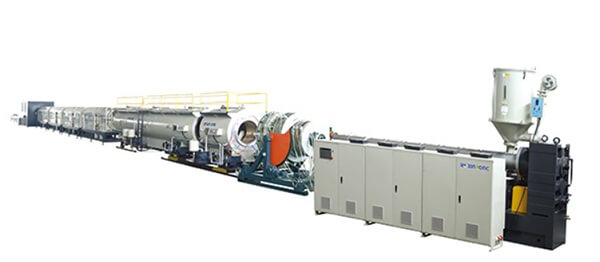

Compared with traditional cast iron pipes, galvanized steel pipes, cement pipes,PPR pipes have the advantages of energy saving and material saving, environmental protection, light weight, high strength, corrosion resistance, smooth inner wall, easy construction and maintenance, and long service life. It is widely used in construction, municipal, industrial and agricultural fields such as building water supply and drainage, urban and rural water supply and drainage, urban gas, electric power and optical cable sheathing, industrial fluid transportation, agricultural irrigation, etc.

Read More »