News

Site Editor

Site

/uploads/5cb96e23627a5.png

PVC is bright in color, corrosion-resistant and durable. Due to the addition of toxic auxiliary materials such as plasticizers and anti-aging agents in the manufacturing process to enhance its heat resistance, toughness and ductility so its products generally do not store food and medicine.

Site

/uploads/5cb96e23627a5.png

PVC is bright in color, corrosion-resistant and durable. Due to the addition of toxic auxiliary materials such as plasticizers and anti-aging agents in the manufacturing process to enhance its heat resistance, toughness and ductility so its products generally do not store food and medicine.

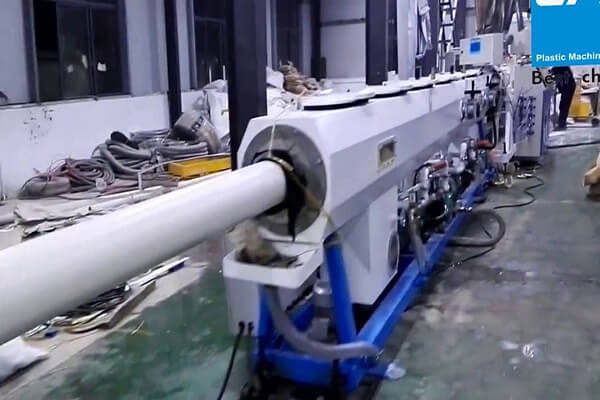

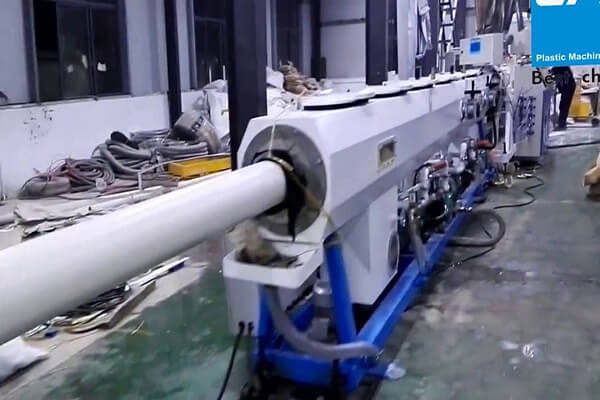

What is the price of PVC pipe production equipment?

Views: 1162

Author: Site Editor

Publish Time: 2020-03-04

Origin: Site

PVC is bright in color, corrosion-resistant and durable. Due to the addition of toxic auxiliary materials such as plasticizers and anti-aging agents in the manufacturing process to enhance its heat resistance, toughness and ductility so its products generally do not store food and medicine.

It is a synthetic material that is loved, popular and widely used in the world today. Its global usage ranks second among various synthetic materials.

(1) Raw material mixing: It is to add PVC stabilizer, plasticizer, antioxidant and other auxiliary materials to the high-speed mixer successively according to the proportion and process. The materials are heated to the set process temperature by self-friction of the material and then the cold mixer reduces the material to 40-50 degrees; this way it can be added to the hopper of the extruder.

(2) Extruder part: This machine is equipped with a quantitative feeding device, which can match the extrusion amount and the feeding amount to ensure the stable extrusion of the product. Due to the characteristics of the conical screw, the feeding section has a larger diameter, and the heat transfer area and shear speed of the material are relatively large, which is conducive to the plasticization of the material. The shear rate allows the melt to be extruded at a lower temperature.

(3) Extrusion die part: PVC that has been compacted, melted, and kneaded and homogenized, and subsequent materials are pushed to the die by the screw. The extrusion die is a key component of pipe molding.

(4) The vacuum shaping water tank is used to shape and cool the pipes. The vacuum shaping water tank is equipped with a vacuum system and water circulation system for shaping and cooling.

(5) The traction machine is used to continuously and automatically pull the cooled and hardened pipe out of the machine head for frequency conversion and speed regulation.

(6) Cutting machine: After the length switch is controlled according to the required length, automatic cutting is performed, and the frame is delayed to implement the flow production. The cutting machine uses the fixed-length switch signal as an instruction to complete the entire cutting process.

(7) The turning operation of the turning frame is realized by the air cylinder through air control. The turning frame is provided with a limit device. After the cutting saw cuts the pipe, the pipe continues to be transported. After the delay, the cylinder enters the work to realize the turning of the material.

It is recommended to go to the physical store according to your budget and actual needs. Generally, the PVC pipe making machine line price will vary according to the style and model of the product, but you can go to the physical store and ask the sales staff to help you make a recommendation based on your actual situation.