2020-08-18

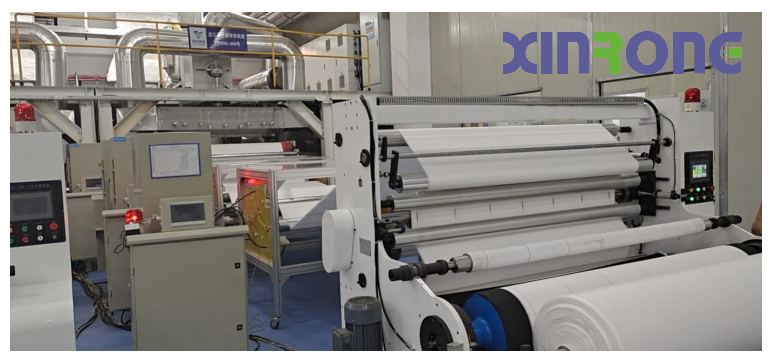

Polypropylene is the main raw material for melt blown fabric. The diameter of fiber can reach 1-5 μ M. These microfibers with unique capillary structure increase the number and surface area of fibers per unit area, so that the meltblown cloth has good filtration, shielding, thermal insulation and oil absorption. It can be used in air, liquid filter material, isolation material, absorbing material, mask material, heat preservation material, oil absorbing material and wiping cloth.

Read More »