2020-04-21

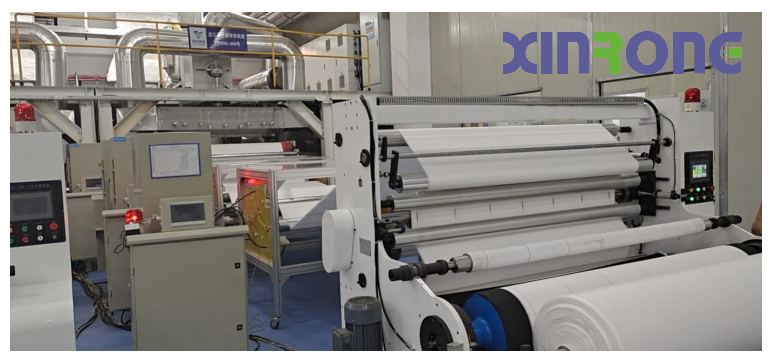

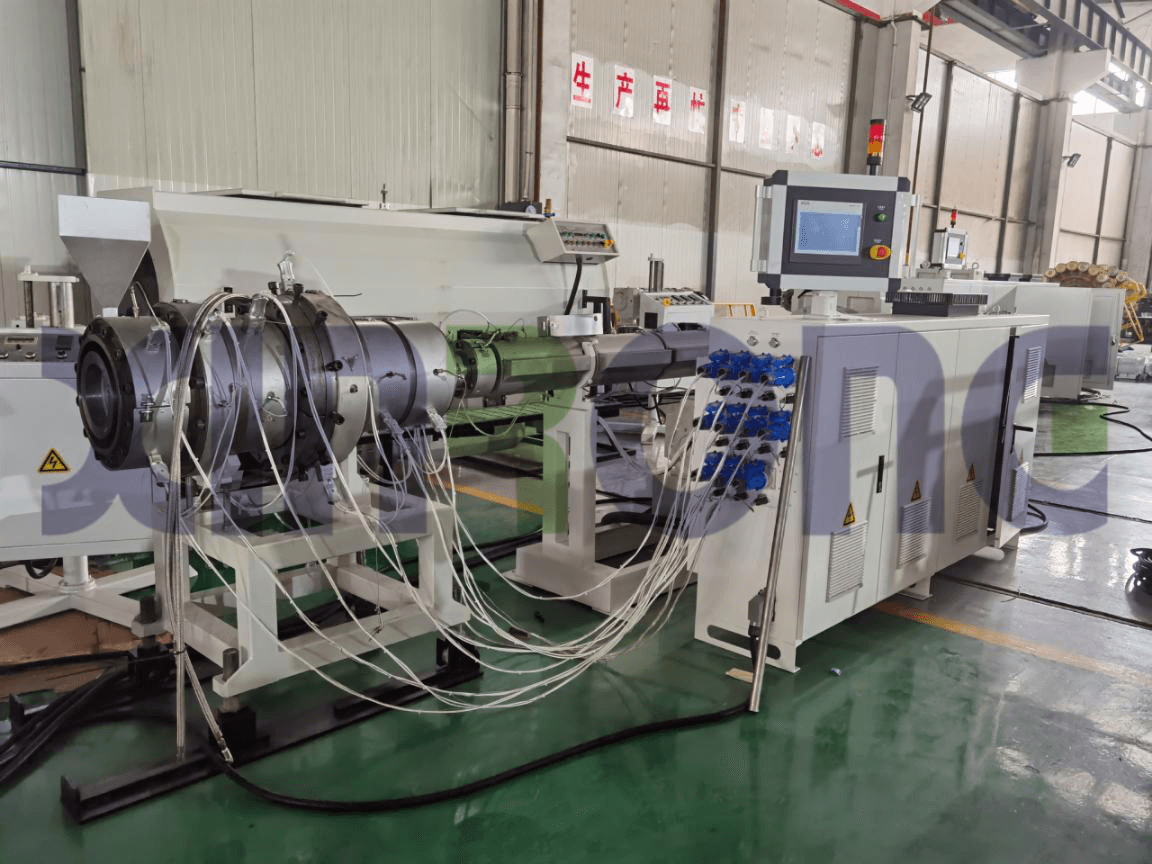

Through years of practical experience, the HDPE water and gas supply pipe production line developed and produced by Xinrong technology has unique structure, novel design, high degree of automation, convenient operation, stable and reliable continuous production. The pipe produced has moderate rigidity, strength, good flexibility, creep resistance, environmental stress cracking resistance and good heat fusion performance, which has become the first choice of urban gas transmission pipe and outdoor water supply pipe.

Read More »